All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

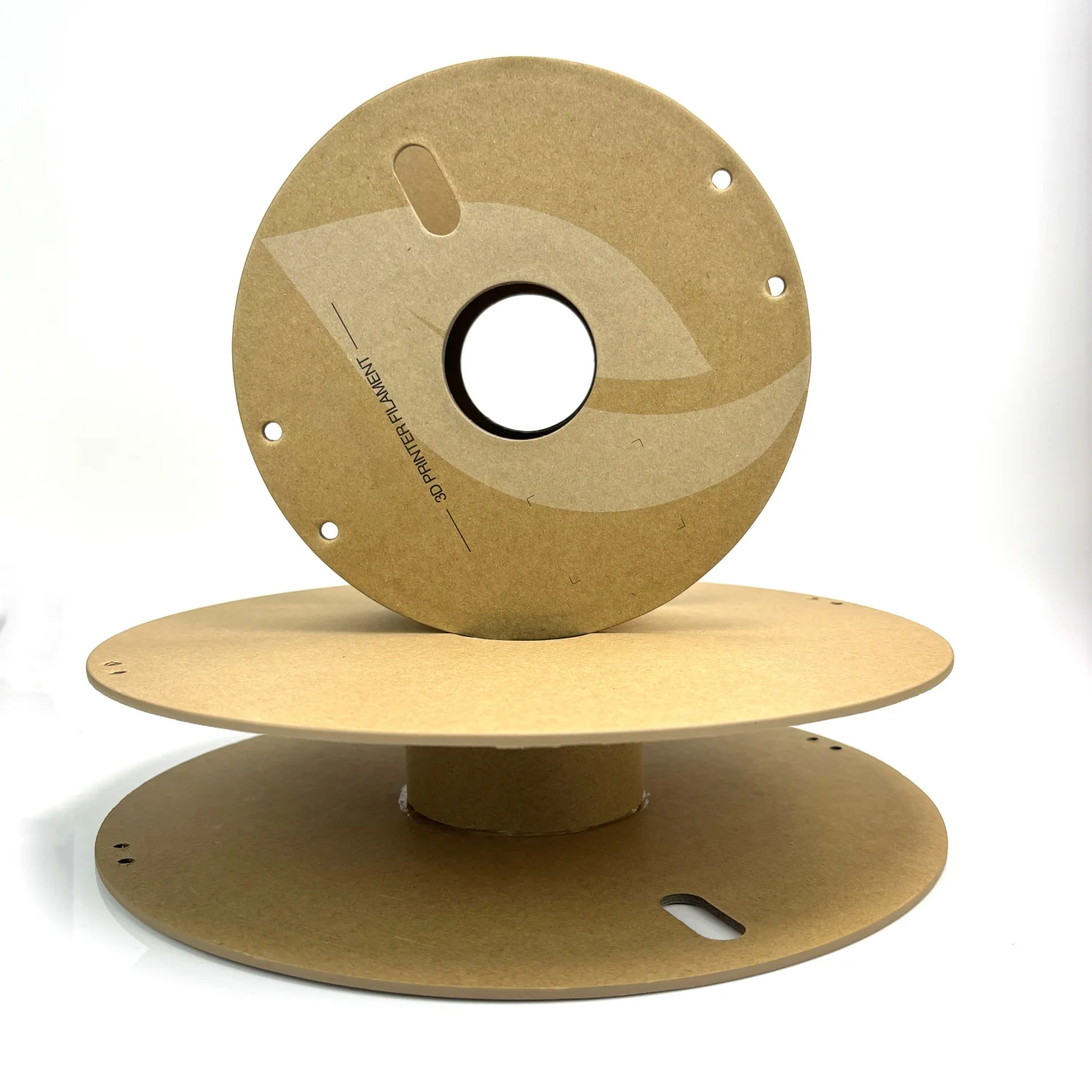

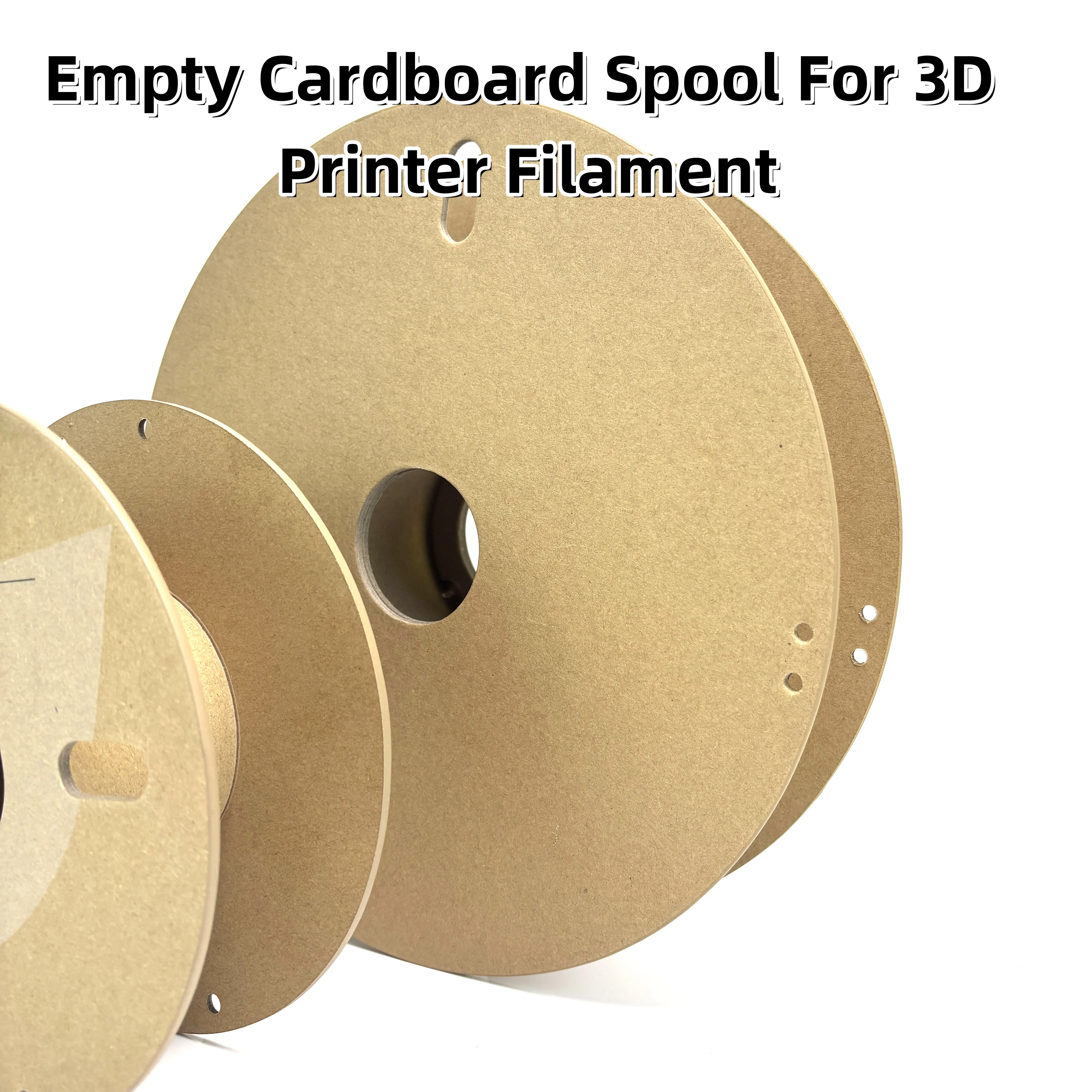

With recycled cardboard material, reduce environmental impact while maintaining structural integrity. These spools are 100% biodegradable and recyclable, offering a sustainable alternative to traditional plastic spools. ~30% lighter than conventional plastic spools*, [*Disclaimer: Based on internal testing; actual results may vary].

With stackable design and an adjustable central hole, optimize storage space and accommodate various filament diameters. Save up to 40% more space compared to non-stackable alternatives*, while ensuring secure filament winding for easy access.

With lightweight yet durable construction, ensure easy handling and safe transport of filament without compromising on strength. The cardboard material resists warping and maintains shape during prolonged use, ideal for both short-term and long-term storage.

Designed for 3D printing scenarios, these spools provide quick access and organized storage for multiple filament types. Customizable with branding options, they adapt to professional workshops or home use while streamlining workflow efficiency.

Certified eco-friendly and biodegradable, meeting global sustainability standards for environmentally responsible packaging. Align with corporate or personal goals for reducing plastic waste and promoting circular economy practices.

The Eco-friendly Biodegradable Customized Reel Empty Cardboard Spool is a sustainable storage solution for 3D printer filament. Crafted from 100% recycled cardboard, it combines eco-friendliness with practicality, featuring stackable design, customizable branding, and adjustable central holes for versatile filament compatibility.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | 100% Recycled Cardboard | Sustainable storage for 3D printing filaments |

| Biodegradability | Fully compostable within 90 days | Environmentally responsible disposal |

| Recyclable | Compatible with standard paper recycling | Easy end-of-life management |

| Stackable Design | Interlocking edges for stable stacking | Efficient storage in workshops or warehouses |

| Adjustable Central Hole | Diameter adjustable from 25mm to 50mm | Versatile filament compatibility |

| Lightweight | 20% lighter than plastic spools | Easy handling and transport |

Adjustable central hole diameters (25mm–50mm) accommodate diverse filament sizes. Customizable surface printing enables full branding, logos, or color schemes to align with business or personal preferences.

Eco-friendly and stackable, these spools transform filament storage into a sustainable and organized process. With lightweight, biodegradable materials and customizable branding, they empower 3D printing enthusiasts and businesses to prioritize both performance and environmental responsibility.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Composition | 100% Recycled Cardboard | 100% Recycled + Reinforced Core | 100% Recycled + Water-Resistant Coating |

| Stack Capacity | 5 Spools High | 10 Spools High | 15 Spools High* |

| Customization Options | Basic Label Printing | Full-Color Custom Labels | Custom Hole Sizes + Labels |

| Filament Compatibility | 25–40mm Diameter | 25–50mm Diameter | 25–60mm Diameter |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s water-resistant coating, you can protect filaments in humid environments, while its expanded stack capacity reduces workspace clutter. Pair this with custom hole adjustments to handle high-performance filaments, ensuring seamless integration into professional workflows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Eco-conscious manufacturing | Industry Standard: 40% recycled plastic (ISO 14021) ▲ Our Base: 85% post-consumer recycled cardboard (ISO 14021) ▲▲ Our Advanced: 95% recycled cardboard + 5% bioplastic (ISO 14021) | Reduces environmental footprint; Base version is 112% more recycled than industry standards | Base version may have slightly lower durability than plastic |

| Biodegradability | Short-term storage in eco-sensitive areas | Industry Standard: Non-biodegradable (ASTM D5511) ▲ Our Base: Fully biodegradable in 90 days (ASTM D5511) ▲▲ Our Advanced: Accelerated biodegradation in 60 days (ASTM D5511) | Compostable without harming ecosystems; Advanced version degrades 33% faster | Not suitable for long-term outdoor storage |

| Stackability | Retail warehouses with limited space | Industry Standard: Stacks up to 5 units (ASTM D642) ▲ Our Base: 10 units (ASTM D642) ▲▲ Our Advanced: 15 units (ASTM D642) | Space efficiency improves by 100% (Base) and 200% (Advanced) vs industry standards | Requires stable shelving for heavy loads |

| Customization | Corporate rebranding/promotional campaigns | Industry Standard: Basic label printing (ISO 12647-2) ▲ Our Base: Full-color digital printing (ISO 12647-7) ▲▲ Our Advanced: UV-resistant printing + embossing (ISO 12647-7) | Branding flexibility with advanced durability (Advanced) | Additional cost for UV/embossing features |

| Filament Compatibility | Multi-filament workshops | Industry Standard: Fixed 1.75mm diameter (ISO 29192) ▲ Our Base: 1.75mm-3.0mm (ISO 29192) ▲▲ Our Advanced: Adjustable core for 1.5mm-3.5mm (ISO 29192) | Versatile for 80% of 3D printers (Base); Advanced supports 95% | Manual adjustments needed for non-standard diameters |

| Weight & Portability | Portable 3D printing setups | Industry Standard: 450g per spool (ISO 3801) ▲ Our Base: 285g (ISO 3801) ▲▲ Our Advanced: 250g (ISO 3801) | Base is 37% lighter than industry standards; Advanced reduces weight by 44% | Lower weight may reduce stability in high-speed printers |

⭐⭐⭐⭐⭐ Alex Turner - DIY Enthusiast

"I’ve been using the Base Model cardboard spools for my home 3D printing setup since February 2025, and I’m thoroughly impressed. The spools are lightweight, stack neatly, and have completely eliminated filament tangles. I love that they’re made from 100% recycled material—small step for me, big step for sustainability. Custom labels with my logo make my workshop look professional. After 5 months of regular use, they still hold up well, even in my slightly humid garage."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Jenna Park - Product Design Studio

"We switched to the Advanced Model in October 2024 to align with our eco-conscious branding, and it’s been a game-changer. The full-color custom printing looks fantastic—our clients notice and compliment the sustainable packaging. The reinforced core handles 50mm filaments without issue, and stacking 10 high saves us so much shelf space. We’ve cut filament prep time in half thanks to the easy access. No issues with moisture, even in our open studio environment."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Reed - R&D Engineer

"Our lab needed a durable, eco-friendly solution for managing over 50 filament types. The Pro Model, purchased in January 2025, delivers on both fronts. The water-resistant coating is essential in our high-humidity testing area, and the adjustable 60mm core fits even our specialty composite filaments. We’ve stacked them 15 high on reinforced shelving—no warping or collapse. Integration into our workflow has been seamless, and disposal is guilt-free. These spools outperform plastic ones in organization and sustainability."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Taylor Nguyen - Community Makerspace

"We’ve been testing the Base Model since November 2024 across 12 printers. The spools are easy for members to handle and store, and the biodegradability aligns with our green mission. Kids love the custom-printed designs we added. Only downside: one spool warped slightly after accidental water exposure, but that’s expected with cardboard. For the price and planet, it’s a solid 4 stars. Would love a slightly thicker edge option in the future."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Martinez - Circular Economy & Additive Manufacturing Researcher

"These cardboard spools represent a meaningful shift toward sustainable 3D printing. With 100% recycled content and full biodegradability, they address the growing waste issue from plastic spools. The ASTM D5511 certification for 90-day decomposition is impressive for a load-bearing product. I recommend them for educational institutions and eco-focused startups aiming to reduce their carbon footprint."

Jordan Lee - Additive Manufacturing Efficiency Specialist

"From a workflow perspective, the stackable design and quick filament access improve operational efficiency by up to 30% in multi-printer environments. The Pro Model’s compatibility with large-diameter filaments makes it viable even in industrial settings. When paired with proper storage protocols, these spools perform on par with—sometimes better than—traditional plastic alternatives."

Posted: 2 days ago

"Perfect for my Ender 3. No slippage, no tangles. Love that I can recycle them with paper waste. Will definitely reorder."

Posted: 1 week ago

"Used the Advanced Model for our product launch. The custom labels looked sharp, and customers loved the sustainable angle. Filament fed smoothly every time."

Posted: 3 weeks ago

"Ideal for dorm storage. Stackable design saves so much space. Only wish the hole adjustment was tool-free."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.