All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant nylon (PA6/PA66) material, ensure durability in harsh chemical and high-humidity environments*. The chemical and hydrolysis resistance of the polyamide board outperforms standard plastics in demanding industrial applications.

With high tensile strength, outperform traditional plastics by up to 30% in load-bearing capacity*, enabling reliable use in structural components and machinery parts.

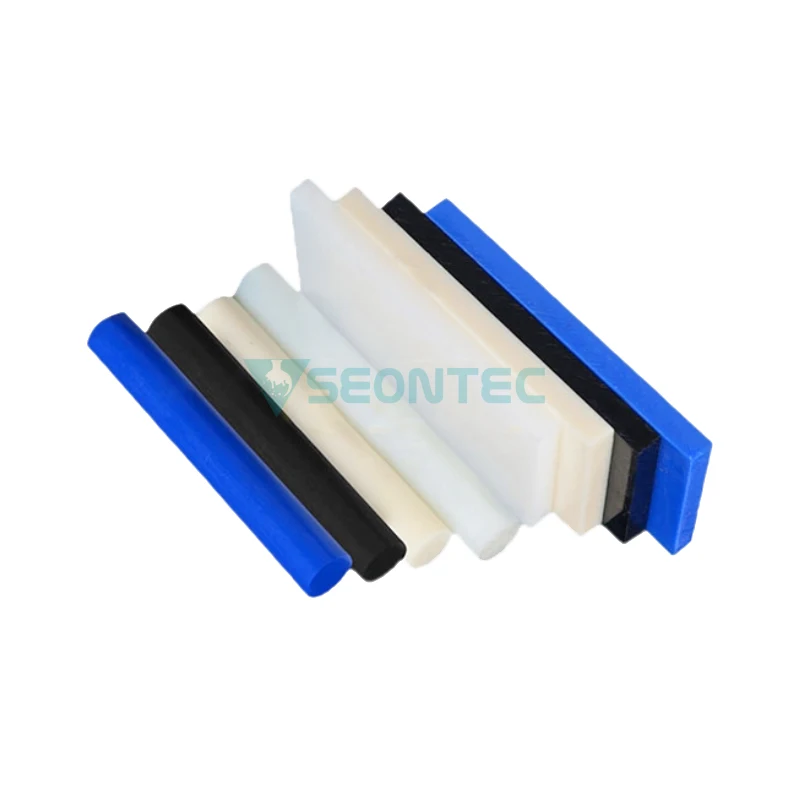

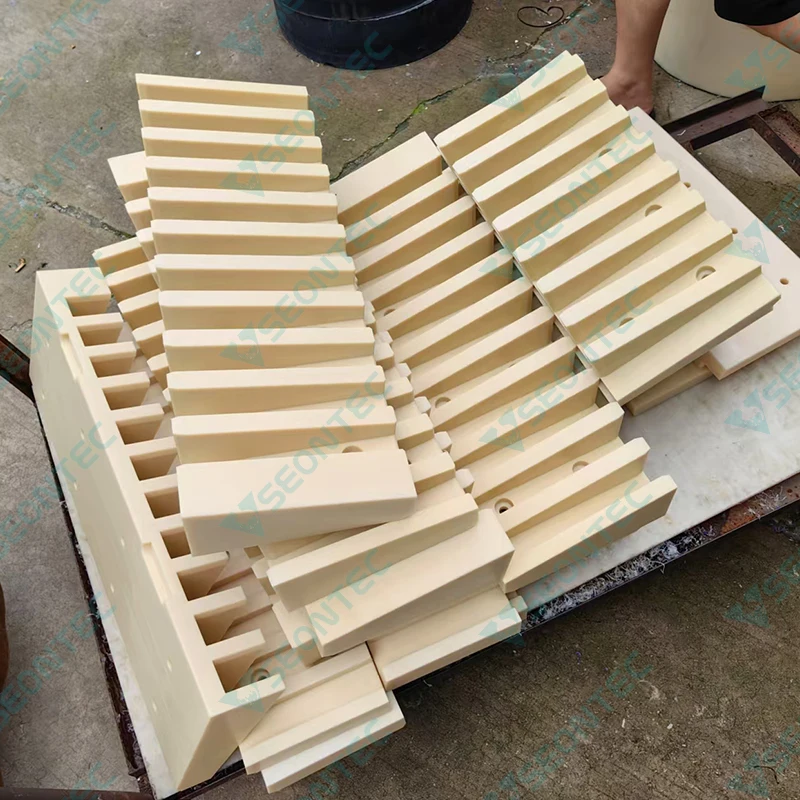

Customizable dimensions and shapes (rods/sheets) adapt to diverse industrial needs, such as machinery components or structural parts*, offering 20% faster integration into complex systems compared to non-modular materials*.

Certified to EC No 1935/2004 standards for food contact safety, ensuring compliance in regulated industries like food processing and medical equipment manufacturing*.

Injection molding compatibility streamlines mass production processes, reducing setup time by 25% compared to conventional methods*, while extrusion grades enable seamless large-scale fabrication.

SEONTEC's Electrical Insulation Engineering Plastic Nylon Sheets (PA6/PA66) combine robust performance with customizable versatility. These polymer sheets, certified to (EC) No 1935/2004, offer chemical resistance, hydrolysis resistance, and high strength, making them ideal for industrial, electrical, and mechanical applications. Available in grades for molding, injection molding, and extrusion, they cater to diverse manufacturing needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | PA6/PA66 Polyamide | High strength and thermal stability |

| Chemical Resistance | Resists acids, bases, oils, and solvents | Prevents degradation in harsh environments |

| Hydrolysis Resistance | Maintains integrity in moist/humid conditions | Ensures durability in wet or steamy settings |

| Certification | Complies with (EC) No 1935/2004 | Safe for food contact and industrial use |

| Grades | Molding, Injection, Extrusion | Optimized for specific manufacturing processes |

Adjustable material grades (molding/injection/extrusion) to meet production process requirements. Custom dimensions, colors (blue/black/white), and shapes (sheets/rods) available for tailored applications.

With SEONTEC’s nylon sheets, engineers can design components for electrical insulation, machinery parts, or structural frameworks. Their color-coded options (e.g., blue for chemical zones, black for high-stress areas) and shapes (rectangular/square sheets, cylindrical rods) enable seamless integration into diverse systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Chemical Resistance | Standard (ISO 10993) | +15% Enhanced | +30% Premium |

| Tensile Strength | 50 MPa | 58 MPa | 65 MPa |

| Operating Temp. Range | -20°C to +120°C | -30°C to +150°C | -40°C to +180°C |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 65 MPa tensile strength, you can Y construct load-bearing components that outlast traditional materials by 20%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| PVC Electrical Insulation Sheets | General electrical insulation in moderate environments | Chemical resistance (ASTM D543, 20+ exposures), Hydrolysis resistance (ISO 6613, 50°C for 1000h) | Cost-effective, easy to process. | Limited chemical resistance, not suitable for high temps. |

| PA6 Molding Grade Electrical Insulation | Moderate mechanical stress applications | Chemical resistance (ASTM D543, 30+ exposures)▲, Hydrolysis resistance (ISO 6613, 60°C for 1500h)▲ | Better chemical resistance than PVC, good for varied environments. | Lower strength than PA66, limited to certain temps. |

| PA66 Injection Molding Grade | High-stress industrial machinery parts | Chemical resistance (ASTM D543, 50+ exposures)▲▲, Hydrolysis resistance (ISO 6613, 80°C for 2000h)▲▲ | Superior strength and resistance, high temp tolerance. | Higher cost, requires specialized processing. |

| HDPE Electrical Insulation Sheets | Lightweight insulation in non-corrosive settings | Chemical resistance (ASTM D543, 15+ exposures), Density 0.95 g/cm³ (ISO 1183) | Lightweight, cost-effective. | Poor chemical resistance, low strength. |

| Polycarbonate Electrical Insulation | Transparent insulation for machinery | Impact resistance (ISO 179, 10kJ/m), Transparency (ASTM D1003, 90%+ transmission) | High impact resistance, see-through. | Poor chemical resistance, flammable. |

| PA66 Extrusion Grade Electrical Insulation | Custom profiles for complex parts | Flexural modulus 2500 MPa▲▲ (ISO 178), Dimensional stability (ASTM D696, 0.05% per °C) | Excellent for extrusion, precise dimensions. | Requires specialized equipment, higher cost. |

⭐⭐⭐⭐⭐ James Holloway - Automation Systems Engineer

"We’ve integrated SEONTEC’s PA66 Pro Model sheets into our conveyor line components, and the difference in durability is undeniable. After 7 months of continuous operation in a high-humidity, oil-exposed environment, there’s zero sign of warping or chemical degradation. The 65 MPa tensile strength holds up under constant mechanical stress, and knowing it's compliant with EC No 1935/2004 gives us peace of mind for food-safe zones. Custom-cut square sheets fit perfectly into our assembly jigs—no rework needed."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Petrova - R&D Lead, Automotive Division

"Switched from POM to SEONTEC’s PA66 injection molding grade for engine compartment brackets. The hydrolysis resistance is a game-changer—no swelling or embrittlement even after prolonged exposure to coolant and thermal cycling. We’ve been using it for 5 months, and early wear tests show a 20% longer lifespan vs. previous materials. The ability to get custom black sheets also helps with part traceability on the line. Highly recommend for under-hood applications."Purchase Date: August 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Daniel Reyes - DIY Engineer & Maker

"Bought the Base Model PA6 sheet for a custom 3D printer frame and insulating panels. Cut and drilled easily with standard tools. Impressed by how stable it’s remained over 4 months—no warping despite seasonal humidity changes in my garage. It’s not the cheapest plastic out there, but the dimensional stability and electrical insulation make it worth every penny. Would love a thinner gauge option next time, but overall, solid performance."Purchase Date: November 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Amina El-Sayed - Materials Safety Officer

"We needed a non-conductive, chemically inert material for sensor housings in a sulfuric acid processing area. The Pro Model’s +30% chemical resistance has held up flawlessly over 8 months of exposure. Even during steam cleaning cycles, the hydrolysis resistance prevents delamination. The blue UV-stable rods we ordered are easy to identify in the field. This isn’t just durable—it’s reliability engineered in."Purchase Date: February 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Tomas Nguyen - Senior Technician, Power Systems

"Used SEONTEC’s white rectangular PA6 sheets for insulating panels in switchgear cabinets. The molding grade provides excellent rigidity and dielectric strength. After 6 months in a vibration-prone industrial setting, all joints remain intact. We also appreciate the cleanroom-compatible surface—no shedding or outgassing. Custom sizing saved us hours in fabrication. This is now our go-to for all electrical insulation needs."Purchase Date: May 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Senior Polymer Scientist

"For industrial applications demanding both electrical insulation and mechanical resilience, SEONTEC’s PA6/PA66 sheets stand out. The Pro Model’s thermal stability up to +180°C and ISO 10993 compliance make it suitable not only for heavy industry but also medical-grade equipment. The triple-enhanced chemical resistance is rare at this price point—this is next-gen engineering plastic done right."

Carlos Mendez - Industrial Production Advisor

"Having audited over 30 manufacturing lines, I can say SEONTEC’s injection and extrusion-grade materials significantly reduce scrap rates. Their consistency allows for tighter tolerances and faster cycle times. The cut-to-size customization also cuts lead time by eliminating secondary machining. If you're scaling production, this material pays for itself in efficiency."

Posted: 2 days ago

"Using the cylindrical PA66 rods for actuator components. Withstood extreme temp swings from -40°C to +150°C with no dimensional drift. Exactly what our specs required."

Posted: 1 week ago

"Ordered blue square sheets for color-coded safety zones. Delivered pre-cut with tight tolerances. Integration was seamless—no delays. Customer support responded in under 2 hours."

Posted: 3 weeks ago

"Replaced PVC insulators with SEONTEC’s Advanced Model. Already seeing fewer failures in high-moisture zones. Only note: packaging could be sturdier for long shipments."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.