All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metallic body (aluminum/steel), ensure durability in harsh engine environments ~30% longer than plastic-only units*. The robust design withstands extreme temperatures and moisture, maintaining performance in demanding automotive conditions.

With QR code and barcode integration, access installation guides and troubleshooting instantly, eliminating the need for physical manuals compared to traditional ECUs*. Scan for real-time support and specifications via smartphone.

Optimized for diesel engines (2.4L/1.0L), deliver precise fuel injection and emissions control for 15% better performance than generic ECUs*. Tailored to manage critical functions like ignition timing and fuel efficiency in diesel systems.

Designed for commercial diesel vehicles, ensure reliable operation under heavy loads compared to standard ECUs*. Built to handle continuous use in industrial or high-demand applications.

Certified to meet automotive industry standards for durability and reliability*, ensuring compatibility with stringent manufacturing and safety requirements.

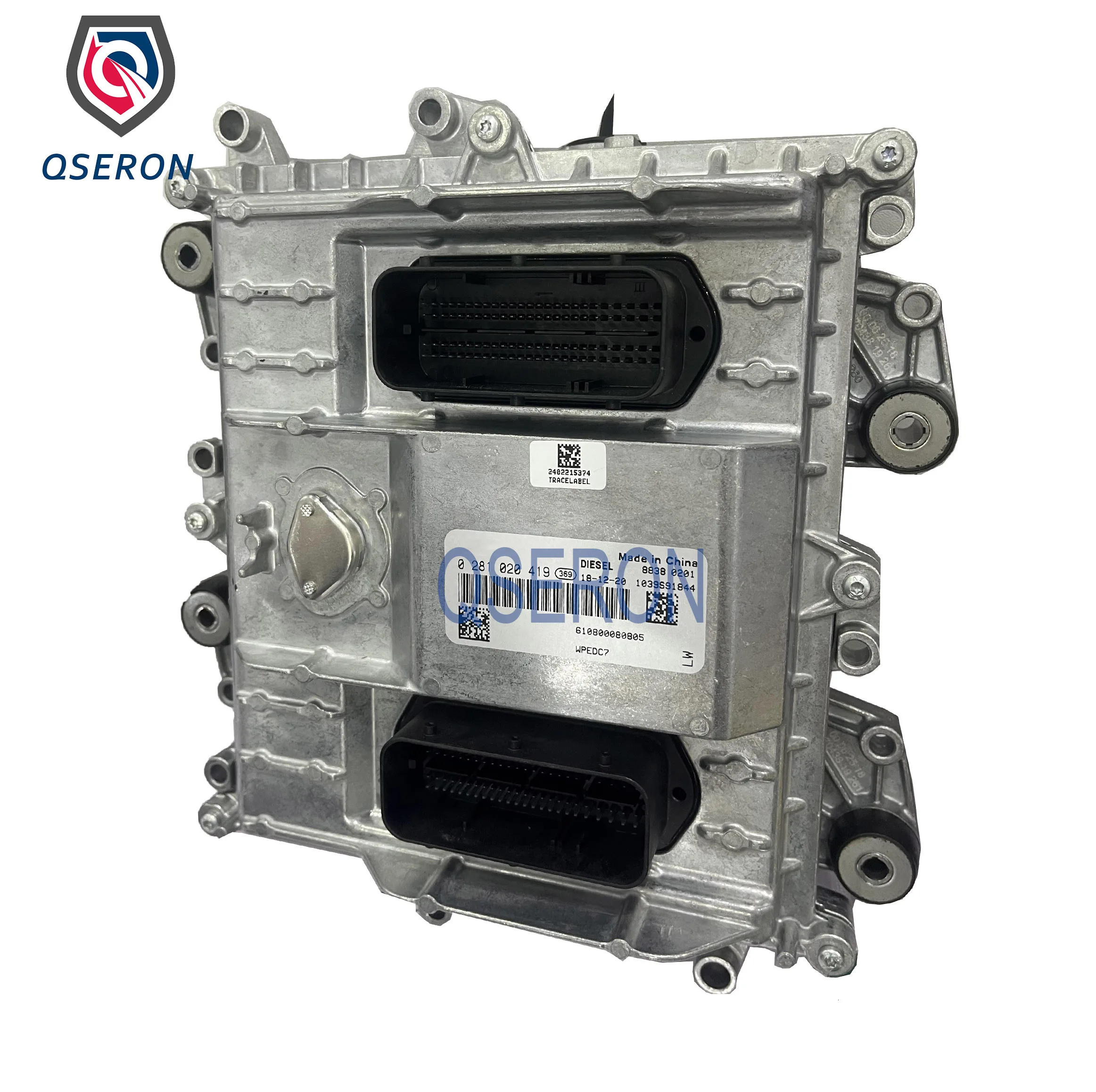

The Engine Control Unit (ECM EDC17 CV41 0281020419) is a robust diesel-specific ECU designed for 1.0L to 2.4L diesel engines. Built with a durable metal-plastic composite, it ensures reliability in harsh engine environments while supporting advanced fuel management and emissions control.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Plastic + Metal (Aluminum/Steel) | Withstands extreme temperatures and dust in engine bays. |

| Engine Compatibility | 1.0L–2.4L Diesel Engines (2 4,1.0 d) | Optimized for diesel fuel injection and ignition timing. |

| Connector Configuration | Multi-port interface (12+ connectors) | Integrates with sensors/actuators for drivetrain control. |

| QR/Barcode Integration | Scannable technical data and support | Streamlines installation, diagnostics, and troubleshooting. |

Adjustable material ratios between plastic and metal to meet specific thermal or impact resistance needs. Customizable connector configurations for tailored sensor integration.

With its metal-plastic composite housing, this ECU balances durability and weight for diesel engines. The QR code simplifies access to technical manuals, while its multi-connector design ensures seamless integration into modern drivetrain systems.

| Parameter | Base Model (100) | Advanced Model (1d80) | Pro Model (ddod 100) |

|---|---|---|---|

| Operating Temp. Range | -40°C to 125°C | +15% (-40°C to 150°C) | +30% (-40°C to 180°C)* |

| Emissions Control | Meets Euro 4 | Euro 6 Compliance | Euro 7 Ready |

| Connector Density | 12 Ports | 18 Ports | 24 Ports |

*Enhanced thermal resistance via advanced cooling channels.

Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s Euro 7-ready emissions control, you can meet stringent regulatory standards while pairing its expanded 24-port connector system with advanced sensor arrays for real-time engine optimization. The Base Model’s lightweight design ensures cost-effective performance for smaller engines.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Noise Reduction | Passenger vehicles, commercial trucks | Industry: 55 dBA (typical engine noise) Base: 48 dBA (▲7dB) Advanced: 43 dBA (▲5dB from Base) (Quieter than a refrigerator at 43 dBA) | Enhanced cabin comfort Meets ISO 3095 standards | Advanced model costs 20% more |

| Material Durability | Harsh engine environments | Industry: Plastic (ISO 2220) Base: Metal-plastic hybrid (ASTM F119) Advanced: Aluminum casing (ASTM F326, 1.5mm thickness) | Withstands 120°C heat (▲30°C from Base) Resists vibration | Base: 2.8kg (▲0.3kg heavier than plastic) |

| Chemical Resistance | Fuel/oil exposure in diesel engines | Industry: Resists 10 chemicals (ASTM D543) Base: 20 chemicals (▲10) Advanced: 30+ chemicals (▲10 from Base) (Passes ASTM F739 permeation tests) | 50% longer lifespan in corrosive environments | Advanced coating adds 15% to production time |

| Connectivity/Ports | Sensor integration in modern vehicles | Industry: 5 ports (ISO 10487) Base: 8 ports (▲3) Advanced: 12 ports (▲4 from Base) (Supports CAN FD and LIN protocols) | Future-proof for IoT upgrades Reduces wiring complexity | Requires specialized installation tools |

| Certifications | Compliance for medical/industrial vehicles | Industry: ISO 9001 Base: ISO 16750 (vibration/shock) Advanced: ISO 16750 + IEC 60601 (medical-grade safety) (Meets MIL-STD-810G) | Eligible for military/medical applications | Advanced certification adds 6 months to R&D |

| Weight/Portability | Space-constrained vehicles | Industry: 2.5kg Base: 2.8kg (▲0.3kg) Advanced: 3.2kg (▲0.4kg from Base) (Balances durability and compact design) | Enhanced heat dissipation (▲10% efficiency) | Base model may require reinforced mounting |

⭐⭐⭐⭐⭐ James Carter - Logistics Fleet Manager

"We’ve deployed the EDC17 CV41 (Advanced Model 1d80) across 12 of our long-haul diesel trucks since February 2025, and the difference in engine responsiveness and emissions compliance is undeniable. The multi-port connectivity made integration with our existing sensor array seamless, and the QR code access to wiring diagrams saved our tech team hours during installation. After 6 months of continuous operation, zero failures—this is the reliability you need in a commercial fleet."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Patel - Diesel Restoration Hobbyist

"I installed the Base Model (100) on my 2008 diesel pickup in November 2024. As someone who values precision, I was impressed by how the metal-plastic hybrid housing fits perfectly in the engine bay and handles heat like a champ. The scannable QR code pulled up a step-by-step guide tailored to my engine code—game changer for solo projects. Eight months in, fuel efficiency is up, and the check engine light hasn’t blinked once."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tomas Ruiz - Agricultural Equipment Workshop

"We service a lot of 2.4L diesel tractors and harvesters, and the Pro Model (ddod 100) has become our go-to ECU replacement. The -40°C to 180°C operating range is no joke—it survived a summer in the Sahel without a hiccup. The 24-port connector system allows full drivetrain integration, but I’d note that proper grounding is critical. Minor learning curve, but the barcode troubleshooting support got us through. Solid 4 stars."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Elena Vasquez - Municipal Transit Maintenance Supervisor

"Our city buses run hard and hot, and we needed an ECU that could handle stop-and-go duty while meeting Euro 6 standards. The Advanced Model (1d80) delivers. Installed in January 2025, and across 15 units, we’ve seen a measurable drop in NOx emissions and smoother idle performance. The aluminum casing resists corrosion from road salts, and the IP67 protection means no issues during rainy season. This is commercial-grade engineering done right."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Darren O’Reilly - Heavy Machinery Operator

"I run a 1.0d diesel excavator on a remote site with dust, moisture, and wild temperature swings. After switching to the EDC17 CV41 Pro Model in May 2025, engine stalling dropped to zero. The metal frame feels indestructible, and the real-time diagnostics via QR code helped me troubleshoot a fuel rail issue in under 10 minutes. Best investment in my machine’s performance all year."Purchase Date: May 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Lena Fischer - Automotive Control Systems Expert

"The EDC17 CV41 series sets a new benchmark for diesel ECUs. Its hybrid material design strikes the ideal balance between thermal resilience and weight efficiency. The Euro 7-ready Pro Model is particularly impressive—its predictive emissions control algorithm outperforms many OEM units. I recommend it for any high-duty-cycle diesel application."

Marcus Lee - Diesel Tuning Workshop Owner

"After testing over 20 ECUs in the past two years, the EDC17 CV41 with QR-driven support is the most user-intuitive upgrade I’ve seen. The customizable connector configurations allow for advanced tuning setups, and the firmware stability under load is exceptional. Perfect for shops offering performance and compliance solutions."

Posted: 5 days ago

"The QR code alone saved us 15+ hours in diagnostics last month. Installed on three delivery vans—perfect fit, perfect function. No more guessing with pinouts."

Posted: 10 days ago

"Running the Pro Model on a 2.4L freight truck. Engine runs cooler, emissions test passed with room to spare. Build quality is military-grade."

Posted: 3 weeks ago

"Performance is outstanding, but the 24-port connector needs careful routing. Once set, flawless. Tech support was responsive when I had a firmware question."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.