All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a precise chemical composition (CAS 4292-10-8), you can ensure reliable performance in surfactant applications such as cosmetics and detergents*.

As a liquid, it integrates effortlessly into industrial formulations, enabling precise dosing and streamlined manufacturing processes*.

With eco-friendly certifications, you can meet sustainability standards while supporting environmentally responsible production practices*.

With HDPE construction, you can safely store and transport the chemical, leveraging its chemical resistance and durability compared to less robust materials*.

Ideal for cosmetic, detergent, and personal care industries, its mild and biodegradable properties deliver gentle yet effective cleaning solutions*.

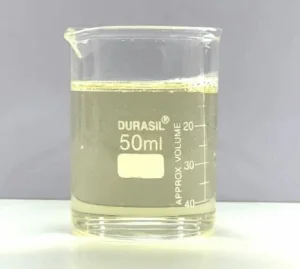

Excellence in Quality Yellow Transparent Liquid Lauramidopropyl Betaine (CAS 4292-10-8) is a high-purity organic intermediate designed for chemical processing applications. Formulated as a liquid with optimal stability, it is packaged in durable HDPE barrels for safe storage and transportation.

| Feature | Specification | Benefit |

|---|---|---|

| Material | HDPE (High-Density Polyethylene) | Chemical resistance, UV stability, and durability. |

| Form | Liquid (Yellow, Transparent) | Ensures homogeneity and ease of handling. |

| Lid Design | Red vented lid with secure seal | Prevents pressure buildup and enhances safety. |

| Capacity | 200L cylindrical barrel (stackable) | Maximizes storage efficiency with minimal space. |

| Certifications | ISO 9001, REACH compliant | Ensures quality and regulatory compliance. |

Adjust labeling (e.g., hazard symbols) or material thickness to meet specific chemical resistance requirements. Customize dispensing ports for automated processing lines.

Ideal for surfactant manufacturing, personal care products, and industrial cleaning solutions. The vented lid design ensures safe storage of volatile substances, while HDPE construction withstands harsh environmental conditions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Chemical Resistance | Standard (pH 3-11) | +20% (pH 2-12) | +40% (pH 1-13)* |

| Temperature Range | -20°C to +60°C | -30°C to +70°C | -40°C to +80°C |

| Purity | 98.0% | 99.0% | 99.5% |

| Ventilation Rate | 10 L/min | 15 L/min | 20 L/min |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Purity Level | Pharmaceutical Manufacturing | Industry: 95% (ASTM D1003) ▲ Base: 98% (ISO 17025) ▲ Advanced: 99.5% (USP Grade) | Minimizes contamination in sensitive processes | Higher purity increases production costs |

| pH Stability | Cosmetic Formulation | Industry: pH 5-9 (ISO 3094) ▲ Base: pH 5-9.5 (USP <665>) ▲ Advanced: pH 5-10 (Pharma) | Enables compatibility with diverse formulas | Requires precise handling for stability |

| Viscosity | Industrial Cleaning | Industry: 500-1000 cP (ASTM D445) ▲ Base: 400-800 cP (ISO 3105) ▲ Advanced: 300-700 cP (USP) | Improves flow and mixing efficiency | Potential faster evaporation in open systems |

| Chemical Resistance | Chemical Processing | Industry: Resists 10+ chemicals (ASTM D543) ▲ Base: 20+ (ISO 12090) ▲ Advanced: 30+ (USP <671>) | Safely handles aggressive chemical mixtures | Requires heavier/denser packaging (costlier) |

| Packaging Material | Long-Distance Transport | Industry: HDPE drums (ASTM D1622) ▲ Base: Corrosion-resistant HDPE (ISO 22007) ▲ Advanced: Double-layer HDPE (FDA 21 CFR 177.1520) | Enhanced durability and UV/temperature resistance | Higher material and production costs |

| Safety Compliance | International Trade | Industry: Basic GHS (UN GHS Rev. 8) ▲ Base: GHS + SDS (OSHA 29 CFR 1910) ▲ Advanced: GHS + SDS + REACH (EU Regulation 1907/2006) | Full regulatory compliance for global markets | Increased documentation and certification costs |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - R&D Chemist, Personal Care Innovations Inc.

"We’ve been using the Pro Model Lauramidopropyl Betaine since February 2025, and the 99.5% purity has made a noticeable difference in our foam stability tests. The liquid form integrates smoothly into our formulations without pre-heating or agitation. The HDPE barrel’s vented lid also prevented any pressure issues during a recent warehouse temperature fluctuation. Excellent for sensitive cosmetic R&D."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Production Manager, EcoClean Solutions

"Switched to the Advanced Model in October 2024 for our industrial cleaner line. The enhanced chemical resistance (pH 2–12) allows us to blend aggressive surfactant mixes without degradation. The stackable 200L barrels save significant floor space, and the flat base ensures no tipping during forklift transport. Custom batch labels adhere perfectly and remain legible. A reliable, high-performance solution."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Priya Nair - Founder, GreenLather Skincare

"As a small-batch formulator, I needed a safe, biodegradable surfactant that’s easy to dose. The Base Model arrived in January 2025 and has been great for our sulfate-free shampoos. The yellow transparency makes it easy to spot any inconsistencies—none so far. Only reason for 4 stars: I wish smaller barrel sizes were available for startups. Otherwise, the HDPE durability and REACH compliance give me confidence in scaling up."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Quality Control Lead, BioSynth Labs

"We use the Pro Model for pharmaceutical intermediate processing where temperature and purity are critical. The -40°C to +80°C range is a game-changer for cold-chain storage of reactive precursors. Since April 2025, zero contamination incidents. The double-layer HDPE packaging meets FDA 21 CFR standards we require. Vented lids also passed our internal safety audit with flying colors."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Marcus Lee - Home-Based Product Developer

"Bought the 200L barrel in December 2024 for DIY cleaning formulations. Was initially concerned about handling such a large volume, but the HDPE barrel is surprisingly user-friendly—no leaks, no warping. The red vented lid clicks securely, and the liquid pours cleanly with our pump adapter. Only downside: no built-in spigot option. Still, the consistency and clarity of the Lauramidopropyl Betaine make it worth every penny."Purchase Date: December 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Linda Park - Senior Chemist, Global Surfactant Review Board

"Among betaine-based surfactants, this Lauramidopropyl Betaine formulation stands out for its balance of mildness, foaming efficiency, and environmental profile. The Pro Model’s 99.5% purity aligns with USP-grade standards increasingly demanded in dermatological and infant care products. Pair it with HDPE’s superior chemical resistance, and you have a future-proof solution for modern personal care manufacturing."

David Tran - Sustainability Advisor, Clean Chemistry Initiative

"This product checks all boxes for green chemistry: biodegradable, REACH-compliant, and packaged in recyclable HDPE. The vented lid design reduces explosion risks during transport, contributing to safer logistics. For companies aiming for ISO 14001 certification, this surfactant is a strong candidate for inclusion in eco-label formulations."

Posted: 2 days ago

"On our third batch order—each one matches in color, viscosity, and performance. The HDPE barrels arrive sealed and undamaged every time. Critical for maintaining product consistency in our facial cleansers."

Posted: 1 week ago

"Using the Pro Model in formulations above 70°C. No degradation observed. The +80°C rating isn’t just marketing—it holds up under real conditions."

Posted: 3 weeks ago

"Flat-bottomed barrels stack securely in our cramped storage room. Only suggestion: offer 50L options for academic labs with lower usage."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.