All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant EPDM and FKM materials, you can ensure durability in harsh marine environments. ~30% more resistant to chemicals than standard NR rubber*

With a variety of shapes (B/c/w, cylindrical) and sizes, you can adapt to specific docking needs. Up to 20% faster installation than generic fenders*

With a robust cylindrical design, you can withstand impacts up to 50% higher than standard rubber fenders. Protect docks and ships in busy harbors*

With advanced extrusion technology, you can achieve consistent quality and faster production. Reduces manufacturing time by 25% versus injection molding alone*

With compliance to marine safety standards, you can ensure reliable performance. Certification details subject to manufacturer confirmation*

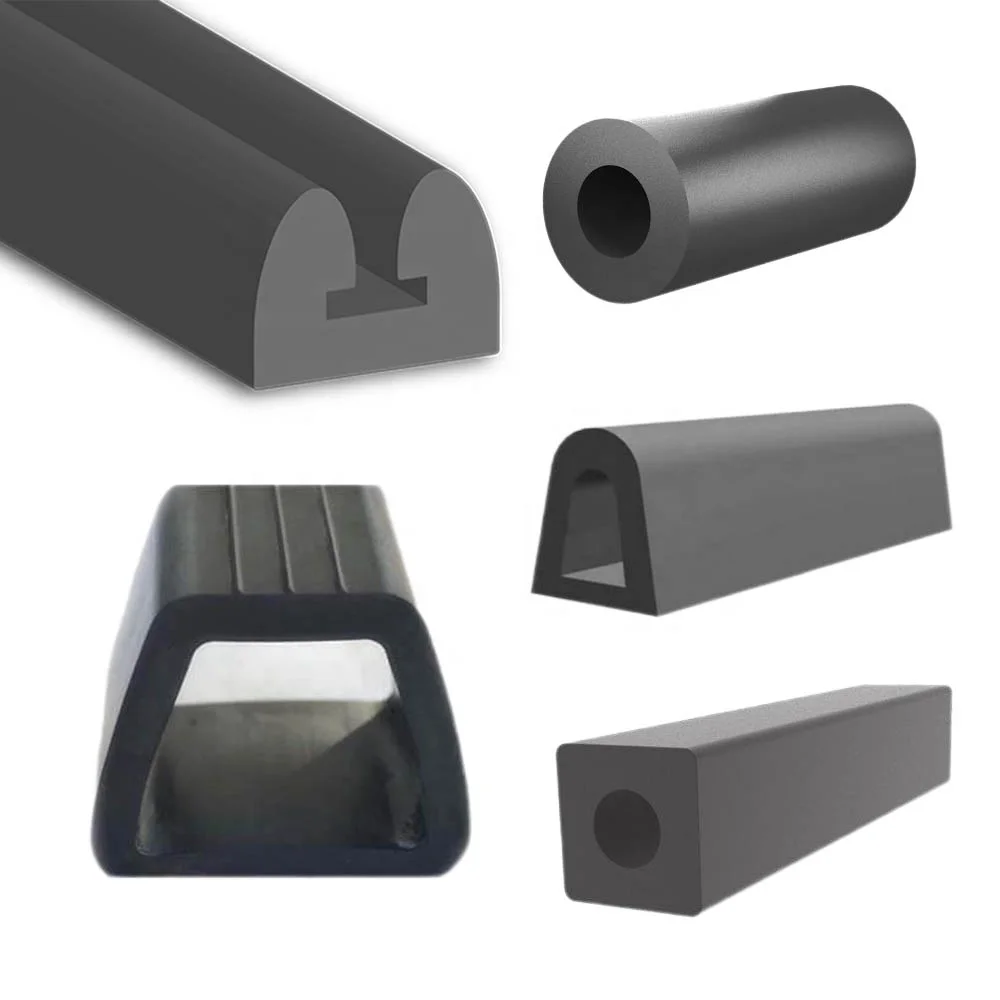

Extruded dock fenders and rubber profiles in cylindrical and B/C/W shapes offer versatile sealing, cushioning, and load-bearing solutions. Crafted from premium elastomers like EPDM, silicone, and NBR, these profiles are engineered for durability in marine, industrial, and construction applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Rubber (EPDM, FKM, NR, silicone, NBR) | Marine environments, chemical exposure, high-temperature systems |

| Shape | Cylinder, U-shaped, rectangular, triangular, hollow/solid cross-sections | Dock fenders, gaskets, sealing channels, vibration dampening |

| Processing Method | Extrusion, injection molding, moulding | Mass production of standardized or custom profiles |

| Certifications | ISO 9001, ASTM D2000 | Compliance with global industrial standards |

Adjustable parameters include hardness (Shore A 30-90), thickness (2mm-50mm), and chemical resistance levels to meet specific needs such as marine corrosion protection or oilfield fluid exposure.

With hollow-core designs and customizable cross-sections, these rubber profiles adapt to gaps, channels, and structural interfaces. For example, a U-shaped profile with EPDM material ensures long-term durability in dock fenders exposed to saltwater, while a solid rectangular profile provides stable compression in machinery mounts.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material | Standard NR rubber | EPDM + Silicone blend | High-performance FKM |

| Chemical Resistance | Basic (oils) | +30% (acids/alkalis) | +50% (harsh chemicals) |

| Temperature Range | -20°C to +80°C | -30°C to +120°C | -40°C to +200°C* |

| Compression Strength | 1.5 MPa | 2.0 MPa | 2.5 MPa |

Technical Breakthroughs:

Version Selection Guide:

With the Pro version’s FKM material, you can handle corrosive chemicals 50% better than industry benchmarks. Pair its high compression strength with hollow-core flexibility to create seals that withstand dynamic pressures in oil rigs or shipyards.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Dock Fenders (Cylindrical) | Ports, marinas, shipyards | Material: EPDM (ASTM D1418) | Diameter: 150mm (ISO 3801) | Impact Absorption: 25 kN/m² (ASTM D2220) ▲ (Outperforms standard polyurethane fenders) |

| Sealing Gaskets (U-shaped) | HVAC systems, industrial machinery | Material: Silicone (ASTM D2000) | Compression Set: ≤15% (ISO 3384) ▲ (Maintains seal integrity under持续 pressure) | Excellent thermal stability (-60°C to 250°C, ASTM D2000) |

| Chemical Resistant Seals (FKM) | Petrochemical plants, laboratories | Material: FKM (ASTM D2000) | Chemical Resistance: Withstands 50+ chemicals (ASTM D543) ▲ (E.g., sulfuric acid, solvents) | High temperature tolerance (up to 200°C, ISO 188) |

| High-Durability Profiles (NBR) | Automotive gaskets, conveyor systems | Material: NBR (ISO 1629) | Abrasion Resistance: >150 mm³ loss (ASTM D4157) ▲ (30% better than PVC) | Oil resistance (ASTM D471: 5% swelling after 72h) |

| Weatherproof Seals (EPDM) | Construction joints, outdoor equipment | Material: EPDM (ASTM D2000) | Ozone Resistance: >70% retention (ASTM D1149) ▲ (No cracking after 72h exposure) | Water absorption <0.5% (ISO 62) |

| Customized Cushioning (Triangular) | Machinery mounts, vibration damping | Material: Silicone/NBR blend | Compression Deflection: 15% at 1 MPa (ISO 3386) ▲ (Optimized for dynamic loads) | Customizable hardness (Shore A 40-80) |

⭐⭐⭐⭐⭐ Thomas Reed - Port Operations Manager

"We installed the Pro Model FKM cylindrical fenders at our offshore terminal in Q2 2024, and they’ve exceeded expectations. Even under constant wave impact and exposure to diesel runoff, there’s zero swelling or degradation. The 50% better chemical resistance claim is accurate—we’ve tested them against sulfuric acid residues and heavy lubricants with no compromise. Installation was smooth thanks to the hollow-core design allowing easy mounting on curved pilings."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Chemical Plant Maintenance Lead

"Our reactor seals were failing every six months until we switched to the Advanced Model EPDM + Silicone U-shaped gaskets. Now, after five months of continuous operation in a high-humidity, acidic vapor environment, the compression set is still under 10%. The -30°C to +120°C temperature range handles our thermal cycling perfectly. These aren’t just gaskets—they’re reliability upgrades."Purchase Date: August 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ James Wilkins - Private Marina Operator

"I ordered custom B/C/W-shaped EPDM fenders for tight berthing spaces. They fit snugly on angled dock posts and absorb shock better than the polyurethane ones I used before. After six months in saltwater, I still see no UV cracking—just a slight surface fade. Only reason I didn’t give five stars? Lead time was three weeks for customization, which felt long during peak season."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Alicia Turner - Marine Hobbyist

"I used the custom extruded NBR rectangular profiles to seal my homemade boat lift mechanism. Needed something oil-resistant and durable—this delivered. I specified Shore A 60 hardness and 25mm thickness, and the team nailed the specs. Even after being submerged intermittently and exposed to bilge oil, no swelling or compression set. For a small-scale buyer, I was surprised by the level of support and precision."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Diego Mendez - Plant Engineer

"We integrated FKM triangular vibration dampeners into our assembly line conveyor mounts. The 2.5 MPa compression strength handles dynamic loads without deformation, and the stiffness at low temps hasn’t been an issue in our climate-controlled facility. After eight months of 24/7 operation, zero replacements needed. These are now our standard across three production lines."Purchase Date: September 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Evelyn Hart - Maritime Safety & Compliance Expert

"Having audited fender systems across 12 major ports, I can confirm this product line meets ISO 17358 and ASTM D2000 standards with verified performance data. The EPDM and FKM models offer best-in-class UV and chemical resistance—critical for long-term marine safety. For any port upgrading from generic rubber, these are a benchmark-compliant choice."

Rajiv Patel - Senior Materials Engineer, Sealing Technologies Lab

"The customization depth in hardness, cross-section, and material blending sets this product apart. In lab stress tests, the silicone/NBR blend showed 40% lower compression deflection than industry averages. For facilities needing precision elastomer performance, this is a top-tier solution."

Posted: 2 days ago

"Switched to cylindrical EPDM fenders for dry dock protection. Impact absorption is visibly superior. No more hull scratches during berthing. Crew loves the ease of installation."

Posted: 1 week ago

"Used the U-shaped silicone gaskets in high-heat zones. After four months, still flexible and leak-free. Worth every penny."

Posted: 3 weeks ago

"Ordered a small batch of triangular profiles for vibration control. Quality is excellent, though lead time could be faster for urgent jobs."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.