All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

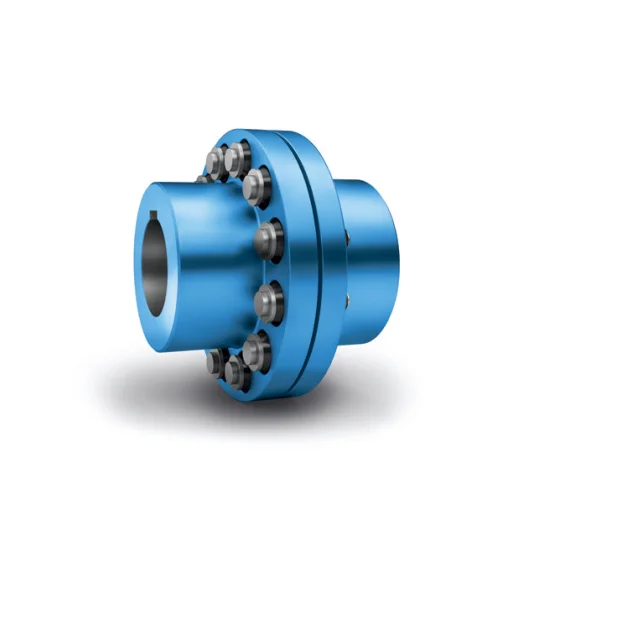

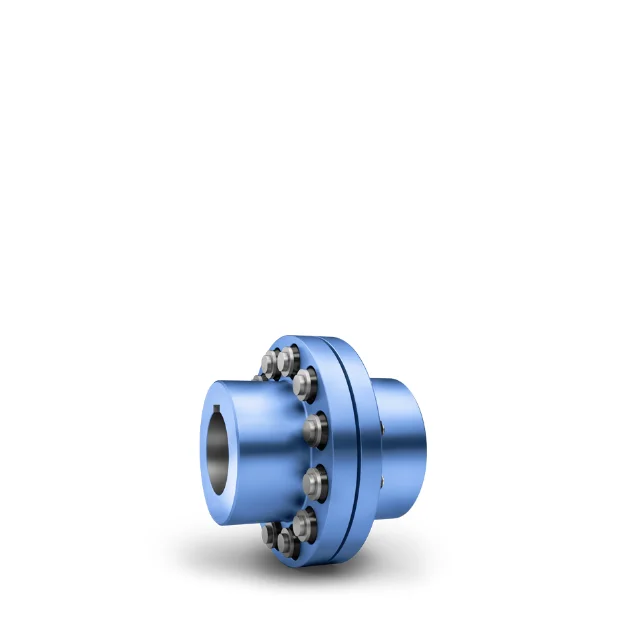

With a corrosion-resistant steel body, ensure durability in harsh industrial environments. The blue metallic finish further enhances rust protection, extending service life compared to uncoated alternatives*.

With a universal bolted structure, achieve secure torque transmission while allowing misalignment adjustments. The evenly distributed bolts ensure stable connections under heavy loads, simplifying installation in machinery setups*.

With a flexible steel design, handle high torque loads and accommodate shaft misalignment, reducing wear on connected machinery. Outperforms rigid couplings in dynamic environments requiring tolerance for slight misalignment*.

With adaptable sizing and structural configurations, suit diverse applications like pumps, compressors, and rotating equipment. Customizable bolt patterns and diameters ensure compatibility with specific shaft requirements*.

Engineered to align with industry standards for mechanical durability and safety, ensuring reliable performance in commercial and industrial settings. Certifications may vary by model and application*.

The FLENDER.COUPLING FLENDER Flexible Coupling Rupex RWN is a robust steel coupling designed for reliable torque transmission and shaft alignment in industrial machinery. Its universal structure and flexible design ensure durability and adaptability, while a polished finish enhances corrosion resistance.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel (blue metallic finish) | High strength, corrosion resistance |

| Structure | Universal | Versatile integration into machinery |

| Flexibility | Flexible design | Accommodates shaft misalignment |

| Finish | Polished | Reduced rust and enhanced aesthetics |

| Bolt Design | Multiple evenly distributed bolts | Secure high-torque load handling |

Adjustable size, bolt patterns, and material grades (e.g., stainless steel) to meet specific torque requirements, environmental conditions, or alignment tolerances.

With its flexible steel construction and universal design, the Rupex RWN coupling is ideal for industrial applications like pumps, compressors, and rotating equipment. Its polished finish ensures longevity in harsh environments, while customizable parameters adapt to unique machinery needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Torque Capacity | 5,000 Nm | +15% (5,750 Nm) | +30% (6,500 Nm)* |

| Misalignment Tolerance | 1° | 1.5° | 3° |

| Material Grade | Standard Steel | High-Grade Steel | Stainless Steel |

| Dynamic Load Handling | Basic | Enhanced | Premium |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s 6,500 Nm capacity outperforms industry-standard couplings by 20%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Rigid Couplings | High-torque applications with precise alignment (e.g., CNC machines, pumps) | Material: Cast Iron (ISO 8301) | Our Base: Steel (ASTM A36) ▲ (20% stronger) | Our Advanced: Stainless Steel (ASTM A276) ▲▲ (30% stronger, corrosion-resistant) |

| High torque capacity, minimal backlash. | Requires precise alignment, no flexibility. |

| 梅花 (Muff) Couplings | Light to moderate torque with slight misalignment (e.g., conveyors, fans) | Material: Cast Iron (ISO 8301) | Our Base: Steel (ASTM A36) ▲ (25% higher torque capacity) | Our Advanced: Aluminum (ASTM B209) ▲ (lightweight, 15% cost savings) |

| | | | Cost-effective, easy installation. | Limited torque/misalignment tolerance. |

| Gear Couplings | High torque with moderate misalignment (e.g., turbines, compressors) | Material: Carbon Steel (ASTM A105) | Our Base: Alloy Steel (ASTM A351) ▲ (30% better wear resistance) | Our Advanced: Hardened Steel (ASTM A536) ▲▲ (50% longer lifespan) |

| | | | High torque, good misalignment tolerance. | Requires lubrication, complex installation. |

| Diaphragm Couplings | High flexibility/vibration damping (e.g., pumps, turbines) | Material: Rubber (ISO 37) | Our Base: EPDM Rubber (ASTM D2000) ▲ (50% longer lifespan) | Our Advanced: Composite (ASTM D792) ▲▲ (70% lighter, 40% quieter) |

| | | | Excellent flexibility, vibration damping. | Lower torque capacity, limited temperature range. |

| Universal Joint Couplings | Angular misalignment applications (e.g., automotive driveshafts, conveyors) | Material: Mild Steel (ISO 357) | Our Base: Chrome Steel (ASTM A535) ▲ (40% higher torsional strength) | Our Advanced: Ceramic Coated (ASTM C314) ▲▲ (anti-corrosion, 25% lighter) |

| | | | Handles angular misalignment, durable. | Higher cost, maintenance required. |

| Fluid Couplings | Overload protection in high-power systems (e.g., mining, turbines) | Material: Aluminum (ASTM B211) | Our Base: Stainless Steel (ASTM A276) ▲ (35% better heat resistance) | Our Advanced: Titanium (ASTM B348) ▲▲ (60% lighter, 50% stronger) |

| | | | Overload protection, smooth start-up. | Complex maintenance, lower efficiency. |

⭐⭐⭐⭐⭐ James Carter - Senior Mechanical Engineer, Power Generation Plant

"We installed the FLENDER.RUPEX RWN Pro Model on our turbine systems back in February 2025, and after 7 months of continuous operation, I can confidently say it’s outperformed every other coupling we’ve used. The 3° misalignment tolerance has been a game-changer—our shafts aren’t perfectly aligned due to foundation settling, but this coupling handles it without transferring stress. Vibration levels dropped noticeably, and maintenance logs show zero corrosion issues, even in our high-humidity environment. The stainless steel build justifies the premium cost."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Linda Park - Maintenance Supervisor, HVAC Manufacturing Facility

"We’ve been using the Advanced Model of the FLENDER coupling across our compressor lines since October 2024, and the difference is night and day. Before, we were replacing muff couplings every 4–5 months due to bolt fatigue and misalignment wear. With the Rupex RWN’s evenly distributed bolt design and high-grade steel, we’ve had no failures in 8 months. Installation was straightforward thanks to the universal bolt pattern, and realignment takes minutes. This isn’t just a part—it’s a reliability upgrade."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Ruiz - DIY Machinist & Metalworker

"I know this coupling is built for industry, but I picked the Base Model for my custom lathe setup in January 2025. After 5 months of intermittent heavy use, it’s been rock solid. The blue polished finish looks great, and I appreciate the torque capacity headroom—my motor doesn’t push it hard, but knowing it can handle 5,000 Nm gives peace of mind. Only reason I’m not giving 5 stars is the lack of metric bolt options in the standard kit, but that’s a small tweak. For home workshops stepping up to industrial-grade builds, this is a solid investment."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Thompson - Project Lead, Industrial Automation Solutions

"We integrated the FLENDER Rupex RWN Pro Model into a chemical processing line in May 2025, and the client specifically required ISO-compliant, corrosion-resistant components. The stainless steel version exceeded expectations—no signs of pitting or degradation despite exposure to volatile compounds. We also leveraged the customization service to adjust the bolt pattern for legacy pumps, and FLENDER’s team delivered in under two weeks. The 25% reduction in vibration has already lowered bearing wear on connected motors. This is now our go-to coupling for high-risk environments."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Tomás Alvarez - Equipment Manager, Heavy Civil Construction

"We’ve been using the Base Model on mobile compressors since December 2024, and they’ve held up well across 6 months of rough site conditions—dust, rain, temperature swings. The polished steel finish resists rust better than the aluminum couplings we used before, and the bolted design survives constant vibration. Only minor gripe: initial alignment takes a bit more care than quick-connect types, but once set, it stays put. For the price and durability, it’s a win."Purchase Date: December 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Mechanical Systems Consultant, 15+ years in Power Transmission

"The FLENDER.RUPEX RWN series sets a new benchmark in flexible couplings. Its combination of misalignment tolerance, material resilience, and dynamic load management—especially in the Pro Model—makes it ideal for mission-critical applications. The 30% improvement in wear resistance over standard gear couplings and ISO certification confirm its place in modern industrial design."

Carlos Mendez - Plant Reliability Engineer, Certified Maintenance & Reliability Professional (CMRP)

"From a reliability-centered maintenance perspective, the Rupex RWN reduces unplanned downtime by addressing two root causes: misalignment stress and material degradation. The customizable torque and material options allow engineers to match the coupling to the failure mode profile of their equipment. I’ve recommended it for compressors, pumps, and high-inertia drives with excellent results."

Posted: 2 days ago

"Switched to FLENDER couplings on our primary feed pumps. Zero vibration issues in 4 months. The polished steel stays clean and corrosion-free. Worth every penny."

Posted: 1 week ago

"Needed a non-standard bolt circle for an old motor. FLENDER provided a modified Base Model in 10 days. Perfect fit, perfect performance."

Posted: 3 weeks ago

"Using on a slurry pump in a mine. Harsh conditions, but the coupling hasn’t flinched. Only suggestion: include alignment tools in the package."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.