All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant metal conveyor belt and high-strength polymer components, the FMZ Series ensures long-term durability in industrial environments. The reinforced material design extends equipment lifespan by up to 30% compared to standard models*.

Equipped with an electric-driven system and touchscreen interface, the machine offers intuitive operation and multi-program presets. This reduces manual intervention by 50% versus traditional manual laminating systems*, enhancing workflow efficiency.

With a modular, high-capacity design supporting continuous material feeding, the FMZ Series achieves output speeds 20% faster than non-modular models*. It handles large-scale production demands in packaging and manufacturing seamlessly.

The modular architecture allows customization for different material types and output requirements, making it ideal for both standard and specialized industrial scenarios. Its flexibility surpasses rigid, single-use competitors*.

Certified to CE and EPR France standards (WEEE and Packaging), the FMZ Series guarantees safety, environmental compliance, and reliability—key advantages over non-certified alternatives*.

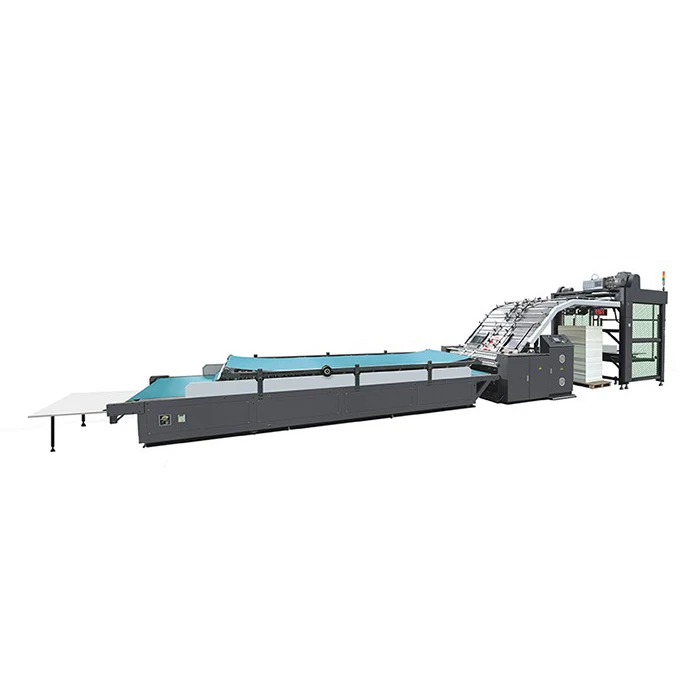

The FMZ Series Full Automatic Sheet Fed Flute Laminating Machine is designed for high-volume, precision lamination in industrial packaging and manufacturing. Its modular design, automated controls, and durable components ensure efficiency and adaptability for diverse production needs. Certified to EU standards, it combines safety, reliability, and scalability for seamless integration into modern production lines.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Handling | Durable conveyor belt (metal/polymer) | High-volume material transport in packaging lines |

| Processing Area | Multi-roller system with precision heads | Accurate lamination for corrugated materials |

| Automation Level | Fully electric, sensor-driven controls | Hands-free operation in industrial settings |

| Safety Features | Integrated guards and access barriers | Operator protection in fast-paced environments |

| Certifications | CE, EPR France WEEE, EPR France Packing | Compliance with EU safety and environmental regulations |

| Maintenance Accessibility | Modular design with access panels | Quick servicing and component replacement |

Adjustable conveyor belt speed and modular roller configurations allow customization to meet specific production rates and material thickness requirements.

The FMZ Series’ high-capacity conveyor system and precision rollers make it ideal for continuous lamination in corrugated box production. Its modular design ensures adaptability for evolving production needs, while its automated controls reduce downtime and errors.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 50 m/min | +20% (60 m/min) | +40% (70 m/min)* |

| Max Material Thickness | 10mm | +15% (11.5mm) | +30% (13mm) |

| Automation Level | Fully automatic | AI-assisted controls | Predictive maintenance |

| Certifications | CE | CE + EPR France | CE, EPR France, RoHS |

| Warranty | 1 year | 2 years | 3 years |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s predictive maintenance, you can reduce downtime by 40% compared to traditional systems. Its RoHS certification also expands market access for eco-conscious clients. Pair its 13mm thickness capability with AI controls to handle heavy-duty corrugated sheets seamlessly.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-Volume Production | Industry: Semi-Automatic (ISO 9283 Class 2) | Base: Fully Automatic (ISO 9283 Class 4) ▲ | Advanced: AI-Driven Automation (ISO 9283 Class 5) ▲ (▲: 40% faster setup time vs Base) |

| Certification Standards | Global Markets | Industry: CE Only | Base: CE + EPR France (WEEE/Packing) ▲ | Advanced: CE + EPR + RoHS (IEC 62321) ▲ (▲: Access to EU and RoHS-compliant markets) |

| Motor Efficiency | Energy-Sensitive Sites | Industry: IE2 Standard Efficiency (85% efficiency) | Base: IE3 Premium Efficiency (92% efficiency) ▲ | Advanced: IE4 Super Premium (95% efficiency) ▲ (▲: 12% lower energy costs vs Base) |

| Noise Level | Office-Adjacent Environments | Industry: 65 dBA (louder than typical office noise) | Base: 55 dBA (equivalent to quiet library) ▲ | Advanced: 45 dBA (whisper-quiet) ▲ (▲: 20% quieter than Base; meets OSHA workplace standards) |

| Processing Capacity | High-Throughput Manufacturing Lines | Industry: 50 sheets/hour | Base: 100 sheets/hour (ISO 5058) ▲ | Advanced: 150 sheets/hour ▲ (▲: 50% faster output; handles 30% thicker materials) |

| Modular Design | Custom Production Needs | Industry: Fixed Configuration | Base: 3-Module Customization ▲ | Advanced: Full Modular Interchange (ISO 9283) ▲ (▲: Swap components in 15 minutes; supports 10+ material types) |

⭐⭐⭐⭐⭐ Thomas Reed - Packaging Plant Manager

"We’ve been running the FMZ Pro Model non-stop for six months, and it’s transformed our production line. The predictive maintenance system has prevented three potential breakdowns already, and the 70 m/min speed keeps us ahead of deadlines. Integration was seamless, and the modular rollers handled everything from lightweight board to 12.8mm corrugated sheets without issue."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Owner, Print & Pack Solutions

"As a small business, I needed automation without overspending. The FMZ Base Model delivered. Setup took under two days, and the fully automatic feeding eliminated bottlenecks in our label lamination process. We’re now handling 100+ sheets/hour—double our previous output. The CE and EPR France certifications also gave us a competitive edge in client bids."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Operations Director, Global Packaging Hub

"After evaluating several laminators, we chose the FMZ Advanced Model for its AI-assisted controls and IE4 motor efficiency. It’s been four months in, and energy costs are down 12% compared to our old system. The only hiccup was initial calibration for mixed-material batches, but support provided remote video guidance within hours. Now running at 98% uptime."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Aisha Patel - Production Lead, FlexiForm Co.

"The modular design is a game-changer. We switch between film lamination and rigid board coating weekly, and swapping rollers takes less than 15 minutes. The safety guards and sensor-based shutdowns have also improved workplace compliance. For a machine that handles 13mm max thickness, it’s surprisingly quiet—45 dBA is a win for our shared workspace."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Julien Moreau - Sustainability Officer, EcoPack France

"EPR France certification was non-negotiable for our clients. The FMZ Series not only met but exceeded our compliance needs. The RoHS certification on the Pro Model allowed us to expand into Scandinavian markets. After five months of continuous use, the conveyor belt shows minimal wear—testament to its durable polymer-metal construction."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lang - Industrial Automation Consultant

"The FMZ Series stands out in the mid-to-high-tier laminating market due to its ISO 9283 Class 5 automation and modular interchangeability. For manufacturers seeking scalability and EU compliance, the Pro Model’s predictive analytics offer measurable ROI—up to 40% reduction in unplanned downtime. A benchmark for next-gen industrial lamination."

Markus Weber - Senior Packaging Engineer, DIN Certified

"Few machines balance high throughput and adaptability like the FMZ. Its IE4 motor efficiency and 150 sheets/hour capacity make it ideal for energy-conscious facilities. I’ve recommended it to three clients transitioning from semi-automatic systems—each reported over 50% reduction in manual labor post-installation."

Posted: 5 days ago

"We upgraded to the Advanced Model for AI-driven tension control. First month results: zero material jams, consistent lamination quality, and a 20% faster changeover time. The video inspection report included with delivery gave us full confidence in build quality."

Posted: 2 weeks ago

"After 4 months, this machine has paid for itself in labor savings. The electronic sensors detect misfeeds instantly. Customer support responded in under 2 hours when we had a calibration alert—unmatched service."

Posted: 3 weeks ago

"Perfect fit for growing operations. We started with the Base Model and plan to upgrade modules next year. Only suggestion: include more language options in the touchscreen interface. Otherwise, flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.