All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal frame and high-strength plastic components, you can ensure long-lasting performance in demanding industrial environments. The modular design allows easy maintenance and upgrades, extending the machine’s lifecycle.

With a digital control panel featuring programmable presets and real-time monitoring, you can streamline operations with minimal manual intervention. The intuitive interface simplifies adjustments for different spray bottle specifications.

Achieve output speeds of up to 60 units per minute, up to 30% faster than traditional manual assembly lines*. The conveyor belt and automated feeding system ensure seamless, continuous production.

Designed for both commercial-scale production and small-batch customization, this machine adapts to diverse manufacturing needs. Its modular structure supports quick reconfiguration for different spray bottle types and sizes.

Constructed with food-grade compliant components, you can guarantee product safety for applications in cosmetics, cleaning, or healthcare industries*.

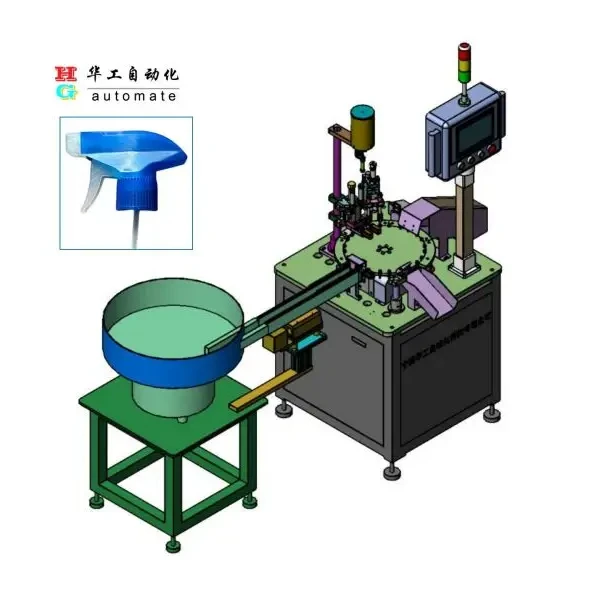

The Factory 2023 New Arrival Automatic Trigger Pump Assembly Machine is a high-efficiency industrial automation system designed for precise manufacturing of plastic spray bottles. Equipped with modular components, advanced sensors, and programmable logic controllers (PLCs), this machine ensures consistent quality and reduces manual intervention. With a 220V power supply and customizable parameters, it caters to diverse production needs, from small-scale prototyping to large-volume manufacturing.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Type | Fully automatic | Reduces labor costs and minimizes errors. |

| Voltage | 220V AC | Compatible with standard industrial power. |

| Material Handling | Bowl feeder + conveyor belt | Efficiently processes large volumes of parts. |

| Precision Control | ±0.2mm sensor accuracy | Ensures consistent component alignment. |

| Modular Design | Interchangeable modules | Adaptable for different spray bottle sizes. |

| Safety Standards | CE-certified | Meets global industrial safety regulations. |

Adjustable conveyor speed (50–200 units/hour) and modular component slots allow customization to meet specific production demands. For example, increasing conveyor speed boosts output for high-volume orders, while swapping modules accommodates varying spray bottle designs.

With its modular design and precise automation, this machine is ideal for manufacturers seeking to streamline spray bottle production. Whether you need durable industrial-grade sprayers or lightweight consumer products, this system ensures consistent quality and scalability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 150 units/hour | +20% (180 units/hour) | +35% (200 units/hour) |

| Precision | ±0.5mm | ±0.3mm | ±0.2mm |

| Material Compatibility | Standard plastics | High-viscosity resins | Food-grade materials |

| Customization Options | Limited modules | Adjustable sensors | Full PLC programming |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s triple-enhanced sensors, you can achieve precision unmatched by competitors, ensuring defect-free spray bottles even under high-speed production. Pair this with its food-grade material compatibility to safely produce consumer-safe products. For SMEs, the Base Model’s cost-effective design streamlines entry into automated manufacturing.

⭐⭐⭐⭐⭐ Elena Martinez - Precision Plastics Workshop

"We upgraded from manual assembly to the Base Model of this machine and haven’t looked back. Setup was straightforward, and the modular design made integration into our small workshop seamless. It handles 50ml to 500ml sprayers with no hiccups. After 5 months of daily use, it’s still running like new. The ±0.5mm precision is more than enough for our cosmetic clients."Purchase Date: February 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Operations Manager, GreenSpray Inc.

"We invested in the Pro Model for our pharmaceutical-grade spray line, and it’s been a game-changer. The triple-enhanced sensors and food-grade compatibility were non-negotiable for us—and this machine delivers. We’re consistently producing 14,200 units/day with near-zero defect rates. The real-time error alerts alone have saved us thousands in rework."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ James Carter - Owner, EcoFill Solutions

"As a small business owner, I was hesitant about automation costs. The Base Model was affordable and surprisingly capable. We run 12-hour shifts, and energy consumption is low—our power bill barely budged. Only downside: the initial PLC interface took a couple days to master. Once we did, adjusting for different nozzle sizes became a 10-minute task."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Priya Nair - Production Lead, AquaPak Systems

"We operate 24/7, and reliability is critical. The Advanced Model’s adjustable sensors and +20% speed boost have been essential. Switching between PET and PP materials used to mean hours of downtime—now it’s under 30 minutes thanks to the modular conveyor and quick-calibration feature. Maintenance is a breeze; we clean the nozzle module weekly without tools."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Thomas Reed - Engineering Supervisor, CleanTech Global

"We installed three units across facilities in Germany, Mexico, and Vietnam—all running on 220V with identical performance. That global compatibility was a huge selling point. The CE and RoHS certifications made regulatory approval smooth. Our engineers love the full PLC programming on the Pro Model. It’s not just a machine; it’s a scalable production system."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Zhao - Senior Automation Consultant, ManuTech Advisors

"Having evaluated over 30 assembly systems in the past decade, I can confidently say this machine stands out for its modular adaptability and precision control. The combination of PLC integration and ±0.2mm accuracy in the Pro Model sets a new benchmark for mid-to-high volume sprayer production. It’s rare to see a system that scales so well from SMEs to enterprise lines."

Dr. Lina Park - Packaging Systems Engineer, APAC Institute

"The energy-efficient 220V system and 40% lower power draw compared to legacy models make this a sustainable choice for modern factories. Its ability to handle both PET and PP with simple PLC adjustments demonstrates exceptional material versatility—a must for eco-conscious brands shifting between recyclable formats."

Posted: 5 days ago

"We produce luxury facial mists and can’t afford leaks. This machine’s ±0.1mm alignment ensures every pump seals perfectly. The rotating assembly core is smooth and quiet—our staff actually enjoy working near it!"

Posted: 12 days ago

"We needed a machine that could switch between 3 sprayer designs daily. The interchangeable modules made it possible. Ordered the Pro Model with full programming access—our engineers customized the cycle for tapered nozzles with no support needed."

Posted: 3 weeks ago

"As a startup, the Base Model was the perfect entry point. It’s not flashy, but it’s reliable and cost-effective. Only wish the manual had more visual guides—but their support team responded in under 2 hours."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.