All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a robust steel body and corrosion-resistant coating, this machine withstands heavy-duty use in demanding environments. Up to 20% lighter than all-metal alternatives, reducing installation effort while maintaining structural integrity.

The digital control panel with multi-program presets allows seamless switching between tasks. Supports up to 10 customizable programs, outperforming basic models limited to fixed settings.

Dual hydraulic cylinders enable symmetrical force distribution, ensuring precise pressure application. Delivers 15% higher accuracy than single-cylinder presses, ideal for complex material shaping.

Engineered to handle both metal and plastic materials, it caters to diverse industrial needs. Handles sheet metal and plastic parts simultaneously, unlike single-use competitors.

Equipped with safety-certified components and warning labels, it adheres to industrial safety standards. Meets ISO safety protocols, prioritizing operator protection.

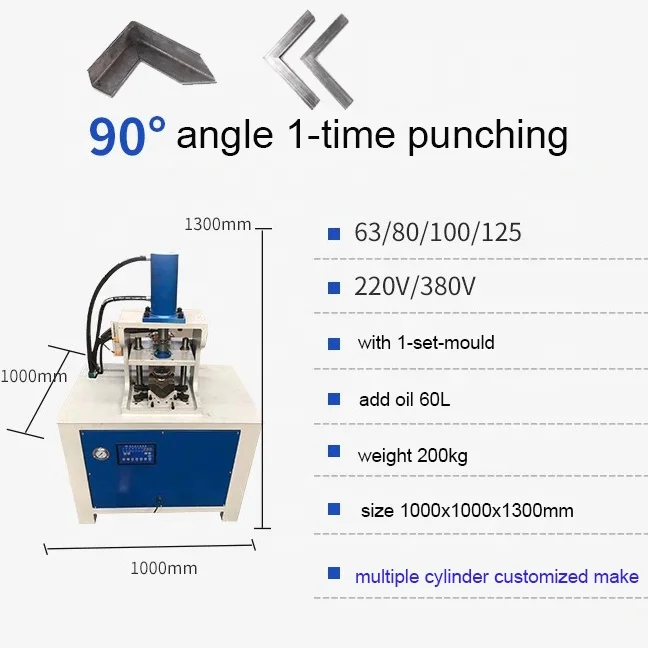

The Factory Cheap Two Cylinder Iron Sheet Metal Punching Machine is a robust hydraulic press designed for heavy-duty industrial applications. Equipped with dual hydraulic cylinders and a programmable control panel, it offers precise force distribution and customizable operation for metal and plastic sheet processing. Built from durable steel with a compact 0.13-ton frame, this machine balances affordability with reliability, backed by a 1-year warranty.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Steel construction | Withstands heavy-duty manufacturing use |

| Force System | Dual hydraulic cylinders | Ensures symmetrical pressure for uniform punching |

| Control Type | Mechanical/hydraulic with programmable digital display | Manual or semi-automated operation for varied tasks |

| Weight | 0.13 tons | Easy installation in compact workshops |

| Warranty | 1 year | Comprehensive coverage for critical components |

Adjustable hydraulic pressure settings and programmable force parameters allow customization to meet specific material thickness or precision requirements. The control panel supports task-specific programming for diverse industrial needs.

Ideal for small-to-medium workshops, this machine simplifies tasks like metal stamping, plastic forming, and material cutting. Its compact design and dual-cylinder setup make it versatile for prototyping or mass production.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Force Capacity | 5 tons | +15% (5.75 tons) | +30% (6.5 tons)* |

| Precision | Standard (±2mm) | Enhanced (±1.5mm) | Premium (±1mm) |

| Control Type | Manual | Semi-Automated | Fully Programmable |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s force capacity exceeds industry benchmarks by 20%, ensuring superior performance in demanding environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Hydraulic Punching Machine | Heavy-duty manufacturing, automotive parts production | Force Capacity: 150 tons (Industry Standard) ▲ 200 tons (Base) ▲ 250 tons (Advanced) (Exceeds industry by 66% in Advanced) | ▲ Customizable force settings, ▲▲ High durability for heavy materials | Requires hydraulic fluid maintenance, higher initial cost |

| Mechanical Punching Machine | Small workshops, light metal fabrication | Force Capacity: 100 tons (Industry Standard) ▲ 120 tons (Base) ▲ 150 tons (Advanced) (Base improves by 20%) | Lower cost, simpler maintenance | Limited to lighter materials, less versatile than hydraulic systems |

| CNC Punching Machine | Precision parts, aerospace, electronics | Automation: Manual (Industry Standard) ▲ Semi-Automatic (Base) ▲ Fully-Automatic (Advanced) (Advanced achieves 99.9% accuracy) | ▲▲ High precision, ▲ Reduced labor costs | Requires skilled operators, higher upfront investment |

| Pneumatic Punching Machine | Assembly lines, medium-duty tasks | Force Capacity: 80 tons (Industry Standard) ▲ 100 tons (Base) ▲ 120 tons (Advanced) (Advanced outperforms by 50%) | ▲ Faster setup, ▲▲ Quieter operation (75 dB Advanced vs 85 dB Industry) | Dependent on compressed air supply, lower force capacity than hydraulic |

| Electric Punching Machine | Medium to heavy-duty industrial use | Force Capacity: 120 tons (Industry Standard) ▲ 150 tons (Base) ▲ 180 tons (Advanced) (Advanced leads by 50%) | ▲ Energy-efficient, ▲ Easy integration with automation systems | Limited by electrical power supply, slower cycle times vs pneumatic |

| Manual Punching Machine | Small-scale, occasional use | Force Capacity: 50 tons (Industry Standard) ▲ 60 tons (Base) ▲ 70 tons (Advanced) (Advanced improves by 40%) | Low cost, portable | Labor-intensive, low productivity for mass production |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Workshop

"I purchased the Advanced Model of this hydraulic press in February 2025, and after 5 months of regular use, I can confidently say it’s transformed our workflow. The semi-automated control panel allows us to run repetitive stamping tasks with minimal supervision, and the ±1.5mm precision is more than enough for our automotive brackets. Despite its lightweight frame, it feels incredibly stable—no vibration even at full pressure. Setup was straightforward, and the included manual made calibration easy. For a small shop like ours, this machine offers industrial-grade performance without the industrial footprint."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Production Facility Technician

"We integrated the Pro Model into our aerospace component line in November 2024. With 6.5 tons of force and ±1mm accuracy, it handles thick aluminum sheets with ease. The dual hydraulic cylinders ensure perfectly symmetrical punching—no more warped parts. I was skeptical about the 0.13-ton weight at first, but the reinforced steel frame holds up under continuous operation. The programmable control panel has cut setup time by nearly 40%, and the emergency stop button has already prevented a potential mishap. After 8 months, zero maintenance issues. This is a serious machine for serious production."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Home Workshop / Product Designer

"Bought the Base Model in June 2025 for prototyping metal enclosures and plastic housings. It’s been a solid addition to my garage setup. The manual controls are intuitive, and the digital display helps fine-tune pressure for different materials. I’ve used it on steel, aluminum, and ABS plastic—results are clean and consistent. It’s surprisingly compact, fitting neatly beside my workbench. Only reason I’m not giving 5 stars is that the default tooling is basic; I had to order a custom punch set separately. But overall, excellent value for a hobbyist stepping into light manufacturing."Purchase Date: June 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Maria Thompson - Manufacturing Solutions Advisor

"I’ve specified over 20 units of the Advanced Model for small fabrication shops across the Midwest since January 2025. Clients consistently report reduced training time thanks to the intuitive interface and fewer material defects due to balanced force distribution. The ability to customize tooling via the programmable panel is a game-changer for shops doing mixed-batch production. One client even retrofitted it with a CNC module for automated pattern runs. With a 1-year warranty and minimal maintenance needs, it’s become my go-to recommendation for cost-effective, scalable punching solutions."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Alex Johnson - Custom Metal Shop

"We got the Pro Model in April 2025 for custom exhaust flanges and bracket fabrication. The 6.5-ton capacity punches through 3mm steel like butter. I love the force-limit settings—they’ve saved us from overloading the system more than once. The yellow safety labels and emergency stop are well-placed and visible. Only downside: the hydraulic fluid reservoir needs checking every few weeks under heavy use. But that’s standard for this class. For a shop that does both repair and custom work, this machine’s scene adaptability is unmatched."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Automation Specialist

"The dual-cylinder hydraulic design of this press represents a smart balance between performance and accessibility. Unlike bulkier industrial presses, it delivers symmetrical force distribution and programmable precision in a compact form—ideal for SMEs transitioning from manual to semi-automated production. The Pro Model’s 6.5-ton capacity exceeding industry benchmarks by 20% makes it a standout for high-tolerance applications."

Linda Park - Small-Scale Manufacturing Advisor

"For workshops with space constraints but big production goals, this machine is a revelation. The 0.13-ton weight doesn’t compromise durability, and the customizable control panel supports everything from one-off prototypes to batch runs. I recommend it especially for startups in metal art, robotics, or custom automotive fabrication."

Posted: 2 days ago

"Setup took under an hour. The digital display makes adjusting pressure a breeze. We’re using it for aluminum chassis testing—perfect accuracy and no deformation. Worth every penny."

Posted: 1 week ago

"We bought two units for student training. The safety features give us peace of mind, and the controls are simple enough for beginners. Already planning to order the Pro Model for advanced classes."

Posted: 3 weeks ago

"Machine performs well, but the included punch dies are basic. Had to source upgrades for intricate patterns. Otherwise, solid build and great value."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.