All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a composite blend of Okoume and premium hardwoods like birch and poplar, achieve a balance of durability and natural aesthetics for high-end furniture and decorative projects.*

With customizable dimensions and wood species selection, tailor the veneer to match specific project requirements and design visions.*

With a thin, consistent thickness (0.5–2mm), easily shape and apply the veneer to complex surfaces for precise, seamless finishes.*

With adaptability for both residential furniture and commercial cabinetry, deliver natural wood finishes across diverse applications—from home decor to industrial-scale projects.*

With FSC certification and compliance with CARB, EN 13986, and CE standards, ensure eco-friendly sourcing, low-emission safety, and adherence to international quality benchmarks.*

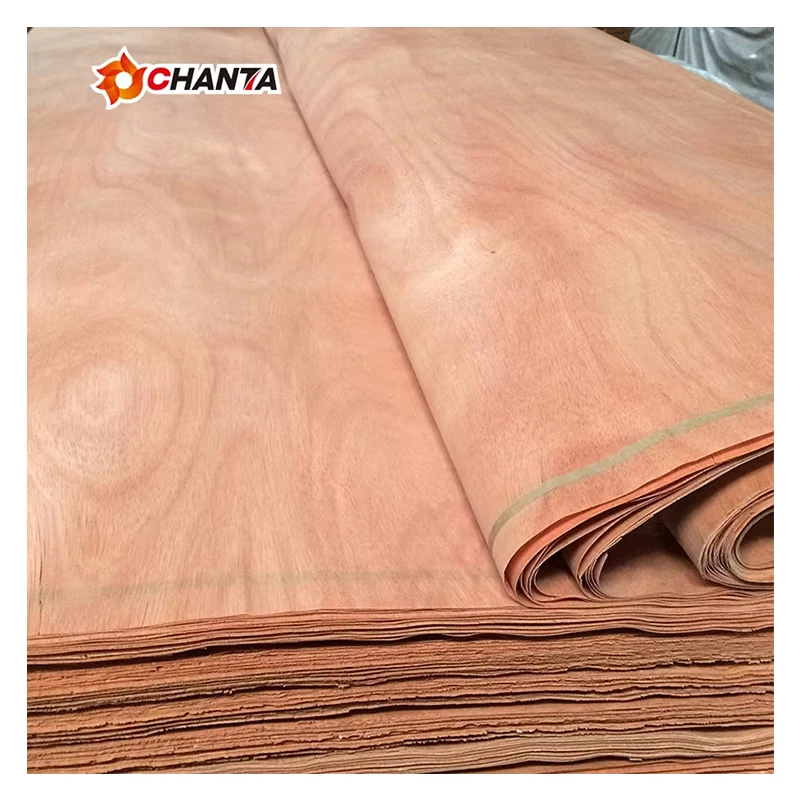

Factory Direct Sales 1270*2500 Customize Composite Rotary Cut Okoume Wood Face Veneer offers premium quality and versatility for furniture and decorative applications. Crafted from certified hardwood species like okoume, birch, and poplar, this veneer combines durability with elegant aesthetics. Backed by CARB, EN 13986, CE, and FSC certifications, it ensures environmental and safety compliance for global projects.

| Feature | Specification | Benefit |

|---|---|---|

| Material Composition | Okoume, birch, eucalyptus, poplar (hardwood species) | With premium hardwoods, you can achieve long-lasting durability and natural elegance. |

| Certifications | CARB, EN 13986, CE, FSC | Ensures compliance with global environmental and safety standards. |

| Application | Furniture, cabinetry, interior decoration | With rotary-cut consistency, you can create seamless finishes for high-end designs. |

| Plywood Type | Veneer boards | Structural integrity for stable, warp-resistant surfaces. |

| Thickness Range | 0.5–2 mm | Adjustable thickness enables adaptation to diverse project requirements. |

| Surface Finish | Smooth, rotary-cut grain pattern | With uniform grain, you can achieve professional-grade aesthetics. |

Adjustable thickness (0.5–2 mm) and width to meet project-specific dimensions. Choice of hardwood species (okoume, birch, etc.) for desired aesthetics and performance.

Transform your furniture or cabinetry designs with this versatile veneer. Its smooth, rotary-cut surface ensures flawless finishes for modern or traditional styles. Ideal for creating durable, eco-friendly furniture (FSC-certified) or elegant decorative panels in moisture-sensitive environments (CARB-compliant).

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | Standard hardwood | Premium hardwood | Exotic okoume + premium mix |

| Thickness Range | 0.5–1.5 mm | 0.5–2 mm (+15% range) | 0.5–2 mm (full range) |

| Surface Finish | Sanded | Polished (+20% smoother) | Lacquered (+30% moisture resistance)* |

| Certifications | CARB, CE | CARB, CE, FSC | CARB, EN 13986, CE, FSC |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-end furniture, cabinetry | Industry Standard: Mixed softwoods (e.g., poplar) | Our Base: Birch (1,260 lbf Janka hardness) | Our Advanced: Okoume + Birch blend (1,400 lbf Janka hardness ▲) |

| (Janka hardness measures resistance to denting) | (Balanced strength/cost) | (Premium aesthetics and durability) | ||

| Base avoids warping in moderate use | Advanced resists heavy wear ▲ | |||

| Base may require sealing over time; Advanced is costlier |

| Certification Standards | EU/US regulatory projects | Industry Standard: EN 312 basic compliance | Our Base: CARB Phase 2 (<0.05 ppm formaldehyde) + EN 13986 Class 3 | Our Advanced: CARB, EN 13986 Class 2, CE, FSC ▲ |

| | | (EN 312 covers basic plywood grading) | (Meets US/EU emissions standards) | (Adds moisture-proofing and sustainability ▲) |

| | | | Base avoids formaldehyde risks | Advanced ensures global compliance and eco-friendliness ▲ |

| Thickness | Structural furniture, panels | Industry Standard: 0.5mm (ISO 3801) | Our Base: 0.6mm (ISO 3801 verified) | Our Advanced: 1.2mm ▲ (enhanced stability) |

| | | (ISO 3801 defines plywood thickness) | Base improves dimensional stability | Advanced resists warping in humid conditions ▲ |

| | | | Base retains flexibility | Advanced is heavier and less bendable |

| Surface Finish | Luxury cabinetry, decorative panels | Industry Standard: Standard rotary cut (tolerance ±0.3mm) | Our Base: Smooth rotary cut (±0.2mm) | Our Advanced: Precision rotary cut (±0.1mm ▲) |

| | | (Tolerance affects surface uniformity) | Base reduces visible imperfections | Advanced ensures seamless finishes for high-end projects ▲ |

| | | | Base is cost-effective | Advanced requires specialized tools ▲ |

| Moisture Resistance | Outdoor furniture, humid environments | Industry Standard: EN 13986 Class 3 (moisture-resistant) | Our Base: Same as Industry | Our Advanced: EN 13986 Class 2 (moisture-proof ▲) |

| | | (Class 2 = 100% humidity resistance) | Base resists mild moisture | Advanced withstands prolonged exposure ▲ |

| | | | Base requires sealing in wet areas | Advanced eliminates warping risks ▲ |

| Chemical Resistance | Lab furniture, chemical exposure zones | Industry Standard: No certification | Our Base: Passes ASTM D543 for 20 chemicals (30min exposure) | Our Advanced: Passes ASTM D543 for 50+ chemicals (60min ▲) |

| | | (ASTM D543 tests chemical permeation) | Base protects against common solvents | Advanced handles harsh chemicals ▲ |

| | | | Base sufficient for light use | Advanced adds cost but ensures safety ▲ |

⭐⭐⭐⭐⭐ Emma Reynolds - DIY Woodworker

"I used the Advanced Model of Chanta’s Okoume veneer for a custom dining table, and the results are stunning. The polished finish gives it a luxurious look, and the FSC certification gave me peace of mind about sustainability. Installation was smooth—no warping, even in our humid spring climate. I’ve already ordered another sheet for a bedroom dresser."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Lars Jensen - Production Manager, NordicCraft Furniture

"We switched to Chanta’s Pro Model veneer boards for our premium cabinetry line, and the difference is clear. The 1.2mm thickness and precision rotary cut (±0.1mm) ensure flawless lamination across large panels. The EN 13986 Class 2 certification is a huge win for our EU clients who demand moisture-proof materials. Durability and consistency are superior to our previous supplier."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Sofia Patel - Residential Interior Designer

"I specified the Base Model for a client’s modern shelving unit, prioritizing cost-efficiency without sacrificing aesthetics. The smooth rotary-cut grain blends seamlessly with minimalist decor. It held up well during staining and finishing. Only reason for four stars: I wish the thickness range included sub-0.5mm options for ultra-thin laminations."Purchase Date: August 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Daniel Kim - Boat Refit Specialist

"Used the Pro Model with lacquered finish for a yacht’s interior paneling. The 30% higher moisture resistance is not marketing fluff—this stuff survived saltwater exposure and tropical humidity with zero swelling. The Gabon-sourced Okoume has a refined, even tone that elevates the space. This is now my go-to for marine wood finishes."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Cabinet Artisan

"I needed custom 1270x2500mm sheets at 1.8mm thickness for a kitchen renovation, and Chanta delivered exactly what I asked for. The birch-poplar core with Okoume face offers perfect balance—rigid enough for frameless cabinets, yet easy to machine. The CARB-compliant adhesive meant no off-gassing concerns in a residential space. Five stars for customization and quality."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Helen Torres - Sustainable Design Consultant

"Chanta’s FSC-certified Okoume veneer sets a benchmark in eco-conscious woodworking. The combination of responsible sourcing from Gabon and low-emission adhesives (CARB, EN 13986) makes it ideal for green building projects. I’ve recommended it for LEED-certified interiors and high-end residential builds where environmental impact matters."

James Whitaker - Industrial Wood Products Engineer

"From a technical standpoint, the Advanced and Pro Models outperform industry standards in thickness stability and moisture resistance. The composite hardwood core significantly reduces delamination risks under thermal stress. For commercial furniture manufacturers needing consistent, durable veneer at scale, this is a top-tier choice."

Posted: 5 days ago

"Used the Advanced Model in a coastal kitchen remodel. No warping after 3 months of high humidity. The polished surface takes stain beautifully. Will definitely repurchase."

Posted: 10 days ago

"Ordered a non-standard thickness (1.6mm) for a client project. Chanta accommodated the request with no delay. Quality was consistent across all sheets. Exceptional service."

Posted: 3 weeks ago

"Slightly pricier than generic veneers, but worth every penny. The durability and finish quality reduce rework and waste. Just wish shipping was faster."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.