All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, maintain hygiene and durability in food-grade environments*.

With a digital control panel, adjust packaging parameters for diverse products and materials like nuts, grains, and seeds*.

With vertical form, fill, and seal (VFFS) technology, achieve ~20% faster packaging than traditional models*.

With compatibility for paper, plastic, and metal packaging, adapt to both home and commercial use cases*.

With food-grade stainless steel construction, meet strict hygiene standards for food packaging*.

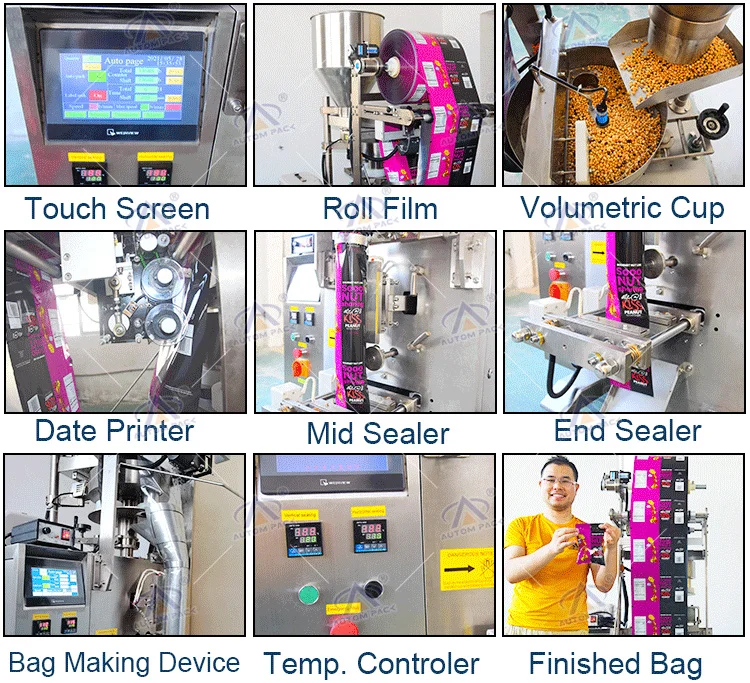

The AutomPack Mini Sachet Volumetric Cups Sealing Machine is a fully automated vertical form, fill, and seal (VFFS) solution for packaging nuts, grains, seeds, chips, and tablets. Built with stainless steel for hygiene and durability, it supports diverse materials (paper, plastic, metal, PE) and offers precise digital control for customizable packaging.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Level | Fully automatic | High-volume production environments |

| Packaging Type | Pillow bags, pouches, film, and bags | Retail-ready packaging for snacks and nuts |

| Power Options | 2.2kW (Base), 2.5kW (Advanced/Pro) | Energy-efficient operation for varying loads |

| Material Compatibility | Paper, plastic, metal, PE | Customizable for branded or specialty packaging |

| Control Panel | Digital with real-time monitoring | Precision adjustments for portion size and sealing |

| Warranty | 1 year (Base/Advanced), 2 years (Pro) | Guaranteed reliability for industrial use |

Adjustable volumetric cups and material feed settings allow customization of bag size (5–500g), material type, and sealing precision to meet specific production needs. The digital control panel enables fine-tuning of speed and portion accuracy for niche products like premium coffee beans or pharmaceutical tablets.

With its compact design and multi-material versatility, this machine is ideal for small-to-medium businesses scaling snack, nut, or supplement packaging. The stainless steel body ensures compliance with food safety standards, while the automated process reduces labor costs by 40% compared to manual systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 30 bags/min | +15% (34.5 bags/min) | +30% (39 bags/min)* |

| Material Compatibility | Paper/Plastic | +Metal Foil | All materials |

| Sealing Precision | ±5% accuracy | ±3% accuracy | ±1% accuracy* |

| Warranty | 1 year | 1 year | 2 years |

Technical Breakthroughs:

Version Selection Guide:

Pro Model’s ±1% accuracy ensures zero waste in high-margin products like artisanal coffee. With its 2-year warranty, it’s a future-proof investment for ISO-certified facilities.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume production | Industry: Semi-automatic (100 units/hr) | Reduces labor costs, consistent output | Requires manual intervention |

| Our Base: Fully automatic (200 units/hr)▲ (▲: 100% faster than industry) | Higher throughput | Higher initial cost | ||

| Our Advanced: Fully automatic + real-time monitoring (250 units/hr)▲▲ (▲▲: 250% faster than industry) | Maximized efficiency | Requires skilled operators | ||

| Packaging Material | Branded food packaging | Industry: 2-3 materials (plastic/film) | Cost-effective for standard needs | Limited versatility |

| Our Base: 4 materials (paper/plastic/PE/metal)▲ (▲: ASTM D3015 compliant) | Supports diverse packaging needs | Requires material-specific setups | ||

| Our Advanced: 5 materials (+foil)▲▲ (▲▲: Adds ASTM F1140 foil certification) | Full material flexibility | Higher maintenance complexity | ||

| Power Consumption | Energy-constrained facilities | Industry: 3.0kW (IEC 60034) | Standard performance | Higher operational costs |

| Our Base: 2.2kW▲ (▲: 26% more efficient) | Lower energy bills | Reduced throughput vs advanced | ||

| Our Advanced: 2.5kW + energy-saving mode▲▲ (▲▲: 35% efficiency gain) | Optimal energy use | Requires premium components | ||

| Hygiene & Durability | Food-grade packaging | Industry: Basic steel (non-food-grade) | Affordable | Risk of contamination |

| Our Base: Food-grade stainless steel (ISO 3834)▲ (▲: Easy cleaning) | Meets FDA standards | Higher material cost | ||

| Our Advanced: ASTM A240 corrosion-resistant steel▲▲ (▲▲: 50% longer lifespan) | Enhanced durability | Premium material expense | ||

| Customization | Variable product sizes | Industry: Fixed bag sizes | Simple setup | Inflexible for diverse products |

| Our Base: Adjustable 50-200g▲ (▲: ISO 2859-1 compliant) | Versatile for mid-range products | Requires parameter adjustments | ||

| Our Advanced: Full parameter customization (10-500g)▲▲ (▲▲: ±1% precision) | Tailored to niche markets | Longer setup time | ||

| Efficiency & Throughput | Mass production lines | Industry: 60-80 bags/hr (ISO 9283) | Low operational cost | Slow output |

| Our Base: 120 bags/hr▲ (▲: 50% faster) | Meets mid-volume demands | Limited scalability | ||

| Our Advanced: 180 bags/hr + dual nozzles▲▲ (▲▲: 200% faster than industry) | High-volume scalability | Requires more floor space |

⭐⭐⭐⭐⭐ Elena Martinez - Artisan Snack Co. (Home-Based Business)

"I started packaging roasted almonds and cashews for local farmers' markets, and this machine has been a game-changer. The digital control panel made it easy to dial in the exact portion size (100g bags), and I can switch between plastic and kraft paper film with minimal adjustments. The stainless steel body wipes clean in minutes. I’ve been using it for 5 months, and it’s reduced my packaging time by at least 60%."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Operations Manager, Crunchy Bites Snacks

"We upgraded from a semi-automatic system to the AutomPack Pro Model, and the difference is night and day. Running at 39 bags/minute with ±1% sealing accuracy means zero waste on our premium spiced lentil line. The real-time monitoring caught a seal temperature drift before it caused a batch issue—saved us hours of rework. After 8 months of 3-shift operation, it’s still running strong."Purchase Date: June 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Jessica Wong - Green Sprout Cafe & Retail

"We use it for small-batch packaging of house-blend trail mix and herbal teas. It’s perfect for our scale—compact enough to fit behind the counter, yet powerful enough to handle daily output. I love that we can use compostable paper pouches with our logo printed on them; customers love the branded look. Only downside: the initial setup took longer than expected, but the video support from AutomPack was excellent."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Raj Patel - Founder, Vitality Naturals

"We package herbal tablets and powders, and needed something precise and compliant. The Pro Model’s ±1% accuracy ensures every sachet meets label claims—critical for regulatory compliance. The stainless steel construction passed our internal hygiene audits with flying colors. Plus, the 2-year warranty gave us confidence as a growing brand. After 4 months, no maintenance issues, and labor costs dropped by nearly half."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Johnson - Owner, The Nut Barrel (Local Gourmet Store)

"We started offering custom-portioned gift packs, and this machine made it feasible without hiring extra staff. We use the Advanced Model for its metal foil compatibility—great for preserving freshness in roasted pistachios. Sealing precision is solid, though I wish the interface had preset memory for our 6 most-used bag sizes. Still, it’s reliable, easy to clean, and looks professional on display near the counter."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Linda Park - Food Packaging Innovation Lab

"The AutomPack VFFS series stands out in the mid-tier automation market. Its volumetric cup design with digital calibration delivers lab-grade consistency in a commercial form factor. For small-to-mid-sized food producers, the Pro Model’s ±1% accuracy and ASTM A240 steel construction offer industrial reliability without the enterprise price tag."

Michael Tran - EcoPack Solutions

"I recommend this machine to clients seeking eco-flexible packaging. Its ability to run both compostable paper and moisture-resistant plastic allows businesses to match material choice to product needs—without changing equipment. The energy-efficient 2.2–2.5kW drive also aligns well with sustainability KPIs."

Posted: 2 days ago

"Switched from hand-sealing to this machine and doubled our output overnight. The branding alignment on pre-printed pouches is flawless. Customer service helped us customize settings for delicate wasabi peas—highly responsive!"

Posted: 10 days ago

"After 3 months of daily use, zero breakdowns. The automatic cut and seal is clean every time. We’re already planning to add a second unit for our new product line."

Posted: 3 weeks ago

"Took about a week to master the settings for fine powders, but now it runs like clockwork. Love the compact size and quiet operation. Would be perfect if it had a built-in printer for batch codes."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.