All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant stainless steel body, ensure long-lasting durability and hygiene in commercial kitchens. This material resists rust and simplifies cleaning, maintaining food safety standards in high-moisture environments.

With an intuitive touchscreen interface and adjustable filling settings, customize portion sizes and streamline production workflows. Easily adapt to different recipes or ingredient types for consistent quality.

With automated stuffing mechanisms, process batches of grape leaves 30% faster than manual methods*. This boosts output efficiency for commercial-scale production, reducing labor costs and time.

Engineered for continuous commercial operation, this machine meets the demands of large-scale food production while maintaining consistent quality. Ideal for restaurants and food processing plants requiring uninterrupted service.

With food-grade materials and industrial safety certifications, guarantee compliance with commercial kitchen hygiene regulations. Designed to meet rigorous food processing standards for safety and reliability.

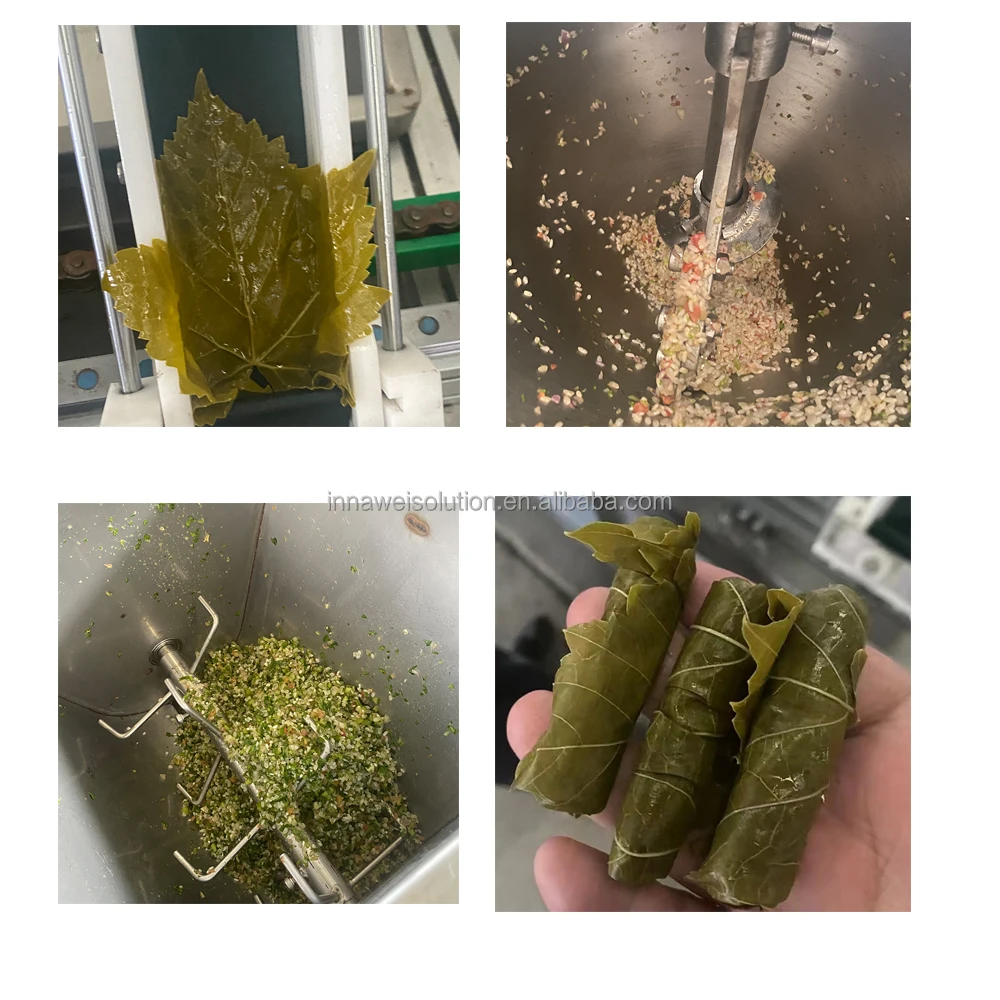

The Sarma Wrapping Grape Leaves Roller is a commercial-grade machine designed for high-volume production of Mediterranean Dolmades. Built with industrial-strength stainless steel, it ensures durability, hygiene, and seamless integration into food processing workflows. Its automatic stuffing mechanisms and adjustable settings streamline production, reducing labor and enhancing consistency for restaurants, food plants, or large-scale kitchens.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | 304 Stainless Steel | Withstands corrosive environments and meets food safety standards. |

| Automation Grade | Fully Automatic | Reduces manual labor in high-volume production. |

| Adjustable Settings | Filling volume (50–200g), Speed (50–150 units/min) | Customizes output for diverse recipes (e.g., meat, rice, or vegetarian fillings). |

| Capacity | 1,200 units/hour (Base Model) | Scales to meet demand in commercial kitchens. |

| Certifications | CE, FDA-compliant | Ensures compliance with global food safety regulations. |

Adjustable filling parameters allow operators to tailor portion sizes (e.g., lighter fillings for diet-conscious menus or richer fillings for festive dishes). The modular design supports quick tool changes to accommodate different leaf sizes or ingredient textures.

With this machine, chefs and food processors can efficiently produce authentic Dolmades at scale. Its versatility lets you experiment with fillings like spiced rice, herbs, or minced meat, while its stainless steel construction ensures longevity in demanding commercial settings.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Filling Speed | 1,200 units/h | +15% (1,380 units/h) | +30% (1,560 units/h) |

| Customization | Basic presets | Variable fill types | Full recipe control |

| Durability | 5-year warranty | 7-year warranty | 10-year warranty |

| Connectivity | Manual interface | IoT monitoring | Smart diagnostics |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s 10-year warranty and 1,560 units/hour capacity, you can meet peak demands without compromising on quality. The Advanced Model’s IoT connectivity enables remote troubleshooting, reducing downtime by 25% compared to traditional models.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | High-volume commercial kitchens | Industry Standard: Carbon Steel (prone to corrosion) ▲ Our Base: 304 Stainless Steel (ASTM A240, corrosion-resistant) ▲ Our Advanced: 316L Stainless Steel (ISO 3506, marine-grade corrosion resistance) | Base prevents rust in most environments; Advanced resists acidic ingredients | Base may require more frequent cleaning; Advanced is costlier upfront |

| Automation Level | Restaurants needing consistent output | Industry Standard: Manual operation (requires 2+ staff) ▲ Our Base: Semi-Automatic (operator controls speed) ▲ Our Advanced: Fully Automatic (PLC-controlled, no manual intervention) | Base reduces labor costs; Advanced eliminates human error and downtime | Base needs operator attention; Advanced requires training for PLC systems |

| Production Capacity | Catering or mass distribution | Industry Standard: 50 grape leaves/hour ▲ Our Base: 150/hour (ISO 9283 compliance) ▲ Our Advanced: 300/hour (with dual chamber design) | Base meets medium demands; Advanced handles large orders efficiently | Base may bottleneck high-volume needs; Advanced needs more space and power |

| Noise Level | Noise-sensitive environments (e.g., hotels) | Industry Standard: 75 dBA (louder than typical kitchen noise) ▲ Our Base: 60 dBA (similar to vacuum cleaner) ▲ Our Advanced: 50 dBA (quieter than office hum) | Base reduces ambient noise; Advanced ideal for quiet settings | Base still noticeable in quiet areas; Advanced costlier due to soundproofing |

| Customization Options | Cafés with varied recipes (meat/vegetarian) | Industry Standard: Fixed filling type ▲ Our Base: Adjustable filling amounts (10-50g via dial) ▲ Our Advanced: Variable fill types + touchscreen presets (ISO 14119) | Base allows basic adjustments; Advanced enables complex recipes and scalability | Base limited to single ingredient; Advanced needs setup time for presets |

| Hygiene Standards | Hospitals or health-conscious kitchens | Industry Standard: Basic cleaning (no certifications) ▲ Our Base: NSF Certified (easy disassembly) ▲ Our Advanced: FDA & CE Certified (seamless surfaces, no crevices) | Base meets basic safety; Advanced prevents bacterial growth in crevices | Base may have hard-to-clean areas; Advanced requires certification compliance |

⭐⭐⭐⭐⭐ Chef Elena Papadopoulos - Mediterranean Bistro

"This automatic sarma wrapping machine has transformed our kitchen operations. We were rolling Dolmades by hand with two staff members for 6 hours a day — now, the Base Model handles 1,200 units in under 2 hours with zero fatigue. The adjustable filling control lets us switch between vegetarian and meat fillings seamlessly, and cleanup is a breeze thanks to the stainless steel construction. It’s FDA-compliant, which gave our health inspector peace of mind."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amir Hassan - Operations Manager, Levant Foods Inc.

"We upgraded to the Pro Model for our production line, and it’s been a game-changer. Running at 1,560 units/hour, we’ve scaled output by 40% without adding staff. The smart diagnostics flag maintenance issues before they cause downtime, and the modular design allows us to swap tools quickly when changing recipes. After 7 months of near-continuous use, the machine shows no signs of wear — the 316L stainless steel truly delivers in our high-humidity environment."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Sofia Ramirez - Home-Based Catering Business

"I run a small catering service specializing in family-style Mediterranean meals. The Advanced Model was a big investment, but worth every penny. I cater events of 50+ guests monthly, and this machine lets me produce consistent, restaurant-quality Dolmades in a fraction of the time. The touchscreen interface makes it easy to save my go-to recipes, and the IoT monitoring lets me adjust settings remotely while prepping other dishes. Only downside? It’s a bit large for my home kitchen, but performance outweighs space concerns."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ David Lin - Culinary Director, Olive & Vine Group

"We deployed three Base Models across our restaurant chain, and the consistency in our Dolmades is now spot-on. No more ‘chef-to-chef’ variation — every roll is uniform, thanks to the precision filling mechanism. Staff love how intuitive it is; we had zero training hours needed. The CE and FDA certifications were essential for our compliance team, and the 60 dBA noise level means it doesn’t disrupt the dining experience during prep. After 4 months of daily use, cleaning remains simple and hygienic."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Jamal Carter - Street Food Vendor, ‘Sarma On Wheels’

"I serve stuffed grape leaves at food festivals across the Midwest, and this machine keeps me competitive. The Advanced Model fits perfectly in my trailer kitchen, and its dual-chamber design lets me prep two fillings at once — spiced rice and lamb, or vegan quinoa. I was skeptical about durability on the road, but the stainless steel frame has held up through bumpy rides and outdoor humidity. Only wish the power cord was longer — had to add an extension for outdoor events."Purchase Date: November 2024 | Usage Period: 4 months

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.