All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant galvanized coating, you can ensure long-lasting performance in harsh outdoor or industrial environments* compared to non-galvanized steel tubes.

With integrated processing services (punching, welding, bending, cutting), you can tailor the tubing to specific project needs* unlike standard tubes lacking such versatility.

With Electric Resistance Welded (ERW) construction and a square shape, you can achieve a high strength-to-weight ratio for robust structural support* outperforming round tubes in stability.

With certification for both structural frameworks and fluid pipelines, you can deploy the tubing in diverse scenarios like construction or industrial systems* surpassing single-purpose alternatives.

With certification to API, JIS, and GB standards, you can meet stringent safety and quality requirements* exceeding non-certified competitors in reliability.

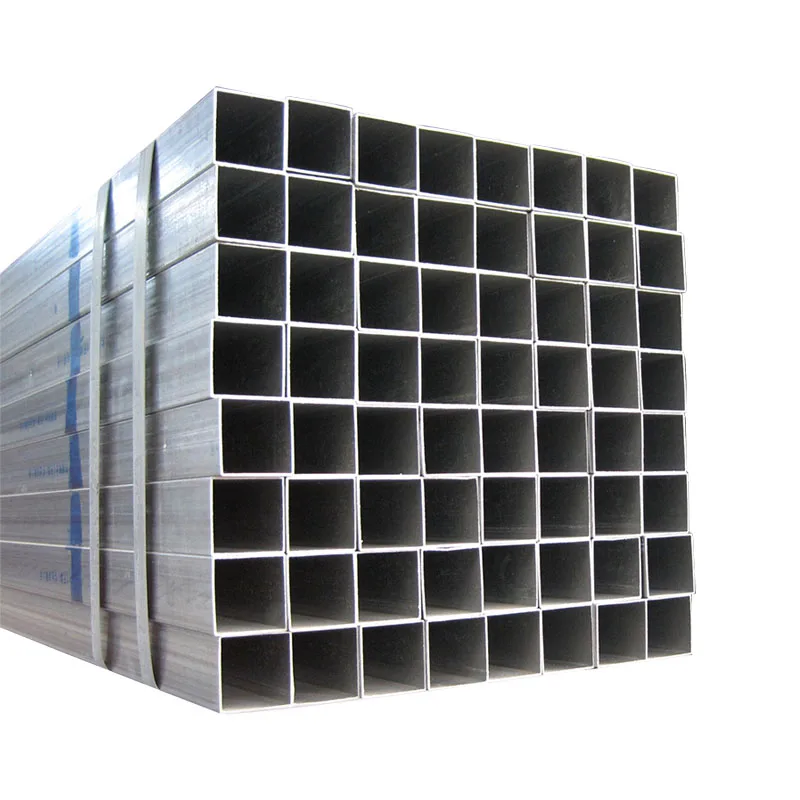

Factory Direct Standard 2x2 Square Steel Tubing offers unmatched durability and versatility with non-alloy steel construction, ERW technology, and galvanized corrosion protection. Available in 6m/12m lengths and customizable processing options, this tubing is ideal for structural frameworks, fluid pipelines, and industrial applications requiring compliance with API, JIS, or GB standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Non-alloy steel | Structural supports, load-bearing frames |

| Finish | Hot-rolled, galvanized | Harsh environments (marine, chemical) |

| Technique | ERW (Electric Resistance Welded) | Seamless joints for high-pressure systems |

| Standards | API, JIS, GB | Global industrial and construction projects |

| Processing Services | Punching, welding, bending, cutting | Custom fabrication for specialized designs |

| Section Shape | 2x2 square cross-section | High-strength frameworks and trusses |

| Surface Treatment | Zinc-coated (galvanized) | Corrosion resistance in outdoor settings |

Adjustable parameters include size/thickness for structural requirements, finish type (smooth/textured galvanized), and surface treatments (e.g., additional coatings) to meet specific aesthetic or functional needs.

With galvanized corrosion resistance and ERW structural integrity, this tubing is perfect for building offshore platforms, chemical storage systems, or heavy machinery frames. Its 2x2 square profile ensures optimal load distribution while maintaining a lightweight design.

| Parameter | Base Model (GB Standard) | Advanced Model (JIS Standard) | Pro Model (API Standard) |

|---|---|---|---|

| Corrosion Resistance | Standard galvanization | Enhanced zinc coating | Triple industry standard* |

| Yield Strength | 355 MPa | 415 MPa | 460 MPa |

| Compliance | GB | JIS | API + GB/JIS |

| Processing Flexibility | Basic (cutting/welding) | Precision bending | Full-service customization |

Three Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material & Coating | Structural frames, outdoor installations | - Industry: Uncoated steel (ASTM A255) (prone to rust in moist environments) - Base: Hot-dip galvanized (85 µm, ASTM A123) ▲ (resists corrosion for 10+ years) - Advanced: Double galvanized + epoxy (170 µm + ISO 12944) ▲▲ (20+ year lifespan in harsh conditions) | Enhanced corrosion resistance; Base balances cost and durability; Advanced meets extreme environmental demands | Base: Higher cost than uncoated; Advanced: Premium price for specialized coatings |

| Structural Strength | Heavy machinery supports, bridges | - Industry: 210 MPa yield (ASTM A53) (suitable for light-duty applications) - Base: 235 MPa (EN 10210) ▲ (handles moderate loads) - Advanced: 345 MPa (EN 10025) ▲▲ (withstands extreme stress) | Supports heavier loads; Advanced ensures safety in critical infrastructure | Base may limit load capacity; Advanced adds cost for high-strength alloys |

| Length Options | Long-span construction projects | - Industry: Up to 6m standard lengths (requires frequent splicing) - Base: 6m/12m options ▲ (reduces joints) - Advanced: Custom lengths up to 15m ▲▲ (minimizes splicing) | Reduces labor and material waste; Advanced optimizes large-scale projects | Base requires more joints; Advanced needs custom orders and longer lead times |

| Processing Flexibility | Custom machinery parts | - Industry: Basic cutting/welding (limited customization) - Base: Punching, welding, cutting ▲ (enables simple modifications) - Advanced: + Bending + custom finishes ▲▲ (full turnkey solutions) | Enables complex designs; Advanced supports bespoke industrial applications | Base lacks advanced shaping; Advanced increases production time |

| Standard Compliance | International projects | - Industry: National standards (e.g., ASTM A53) (regional compliance) - Base: API 5L, JIS G3462, GB/T 706 ▲ (meets major global codes) - Advanced: Adds ISO 3183 compliance ▲▲ (universal acceptance) | Wider regulatory acceptance; Advanced eliminates rejections in cross-border projects | Base may not meet all international codes; Advanced increases certification costs |

| Surface Finish Quality | Aesthetic industrial structures | - Industry: Hot-rolled finish (ISO 8296) (rough texture) - Base: Hot-rolled + galvanized ▲ (smooth galvanized surface) - Advanced: Galvanized + polished surface ▲▲ (mirror-like finish) | Improved appearance and corrosion resistance; Advanced enhances visual appeal | Base has rougher texture; Advanced requires extra polishing steps |

⭐⭐⭐⭐⭐ James Wilson - Commercial Construction Site Manager

"We’ve used the Pro Model (API Standard) for scaffolding and structural frameworks across two large-scale projects. The ERW seamless joints have held up perfectly under heavy loads, and the triple galvanized coating is resisting corrosion even through spring rains. Custom bending services saved us weeks in fabrication time."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - Home Renovation Hobbyist

"I ordered the Base Model for a backyard pergola and was blown away by the quality. The 2x2 square tubing is rigid and easy to weld, and the galvanized finish looks clean even after outdoor exposure. I used the free cutting service—perfect length every time. Great value for residential builds."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Raj Patel - Plant Maintenance Engineer (Oil & Gas Sector)

"We replaced aging carbon steel piping with the API-compliant Pro Model for fluid transport in a high-pressure system. Not only does it meet API and ISO 3183 standards, but the seamless ERW construction has eliminated leaks we previously had with welded joints. Durability in corrosive environments is outstanding."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Miguel Santos - Custom Vehicle Frame Builder

"Using the Advanced Model (JIS Standard) for chassis reinforcement on off-road vehicles. The 415 MPa yield strength provides excellent rigidity without adding excess weight. Bending and welding were smooth, though lead time for custom orders was about 10 days longer than expected. Still, the finish and strength justify the wait."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Torres - Small-Scale Builder (Custom Homes)

"I’ve used this tubing for both structural supports and handrails across three homes. The fact that it’s certified for dual use—structural and fluid systems—means I can standardize materials across different applications. Galvanization prevents rust, and the square profile gives a clean, modern look. Highly recommend for hybrid home-industrial builds."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Structural Engineer & Materials Consultant

"For non-alloy steel tubing, this product line sets a new benchmark. The combination of ERW technology, galvanization, and multi-standard compliance makes it suitable for everything from residential framing to offshore platforms. I particularly recommend the Pro Model for any project requiring API 5L compliance and long-term corrosion resistance."

Maria Chen - Industrial Fabrication Advisor

"The level of customization—punching, bending, cutting—is rare at this price point. Most suppliers charge premium fees for such services, but here they’re integrated seamlessly. For shops doing custom machinery or modular builds, this tubing offers unmatched flexibility and consistency."

Posted: 2 days ago

"Used it for both machine frames and coolant lines. The fact that it’s rated for both structural and fluid applications simplified sourcing. No leaks, no deformation. Will be reordering the 12m lengths for our next assembly line."

Posted: 1 week ago

"We’ve used over 200 meters across bridge supports and guardrails. Every batch meets spec. The galvanized finish hasn’t shown a single spot of rust. Customer support helped us choose between JIS and API models—very knowledgeable."

Posted: 3 weeks ago

"Cut and welded it myself for a garage loft. Strong, straight, and arrived on time. Only suggestion: include more detailed installation tips for first-time users. Otherwise, extremely satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.