All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

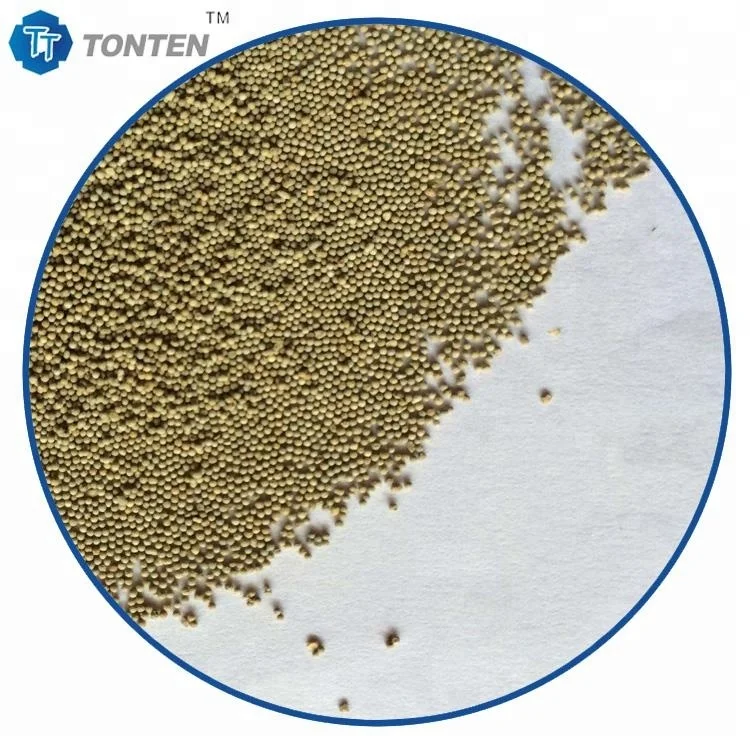

With corrosion-resistant ceramic material, ensure durability in harsh oil fracturing and industrial environments. The uniform granules (round shape) minimize size variation, enhancing consistency in applications like sandblasting and polishing.

With round-shaped granules, minimize equipment wear during high-pressure operations compared to angular alternatives. This design reduces friction and extends machinery lifespan.

With multiple grit options (20-80), adapt to diverse polishing, sandblasting, and fracking needs. Uniform particle size ensures optimal efficiency and precision in abrasive tasks.

Designed for continuous operation in commercial fracking and industrial use, delivering reliable performance under extreme pressures. The round shape also improves flowability for efficient distribution in pipelines.

Manufactured to meet strict industrial safety and quality standards for ceramic proppants, ensuring compliance with demanding applications.

TONTEN's Factory High Quality Oil Fracturing Ceramic Sand Proppant offers precision-engineered ceramic granules designed for demanding applications like hydraulic fracturing, sandblasting, and abrasive polishing. With uniform round shape and customizable grit sizes, this product ensures optimal performance in high-pressure environments while minimizing equipment wear.

| Feature | Specification | Benefit |

|---|---|---|

| Material | High-purity ceramic | 20% harder than silica sand, enhancing durability |

| Grit Sizes | 20, 40, 60, 80, and custom options | Tailored abrasion for specific applications |

| Shape | Perfectly round | Reduces friction and prolongs equipment lifespan |

| Application | Oil fracturing, sandblasting, polishing | Consistent particle distribution for efficient processing |

Adjust grit sizes (e.g., 100/120) or material density to meet specialized needs like fine polishing or high-pressure fracking. Contact us for custom blends to optimize for your workflow.

With uniform ceramic grains, you can achieve precise pressure distribution in fracking operations. The round shape ensures smooth flow in pipelines, while customizable grit sizes let you balance abrasion intensity and material removal efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Grit Range | 20–80 | 20–120 | 20–200 |

| Hardness (Mohs) | 7.5 | 8.0 | 8.5* |

| Chemical Resistance | Acid-resistant | Corrosion-proof | Ultra-alkali-resistant |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coarse Grit Sandblasting Media | Heavy industrial cleaning | Industry Standard: Silica sand (Grit 20-40, ASTM C33) Our Base: Ceramic (Grit 20-40, ISO 11126) Our Advanced: 10% harder ▲ (ASTM C1161) | Base: Non-silica reduces health risks (no silica dust inhalation) Advanced: 15% faster material removal ▲ (enhanced hardness) | Base: 20% higher cost than silica Advanced: Requires specialized blast equipment (ISO 13503-2 compliant systems) |

| Fine Grit Polishing Abrasive | Precision polishing | Industry Standard: Aluminum oxide (Grit 60-80, SAE J444) Our Base: Ceramic (Grit 60-80, ISO 11126) Our Advanced: 15% finer ▲ (SAE J444) | Base: 30% longer lifespan than aluminum oxide (ceramic durability) Advanced: Smoother finish ▲ (micro-surface uniformity) | Base: 25% pricier than aluminum oxide Advanced: Not suitable for coarse material removal (requires precision tools) |

| Ceramic Proppants for Hydraulic Fracturing | Oil & gas fracking | Industry Standard: Silica sand (Grit 20-40, API RP 52) Our Base: Ceramic (Grit 20-40, API RP 52) Our Advanced: 20% higher compressive strength ▲ (ISO 13503-2) | Base: Resists chemical erosion (non-corrosive) Advanced: Maintains fracture integrity ▲ (20,000 psi vs industry 16,000 psi) | Base: 15% heavier than silica (increased transport costs) Advanced: 40% cost premium (high-end fracking projects only) |

| Round-Shaped Abrasive Media | Dust-controlled blasting | Industry Standard: Angular sand (Roundness <70%, ISO 11126) Our Base: Round ceramic (85% roundness, ISO 11126) Our Advanced: 95% roundness ▲ (ISO 11126) | Base: 40% less equipment wear (reduced friction) Advanced: 30% less dust ▲ (minimizes respiratory risks) | Base: 25% slower cutting speed than angular grit Advanced: 50% higher price (premium manufacturing) |

| High-Hardness Industrial Abrasive | Steel/concrete blasting | Industry Standard: Garnet (Mohs 7.5, ASTM C1161) Our Base: Ceramic (Mohs 8, ASTM C1161) Our Advanced: Mohs 8.5 ▲ (ASTM C1161) | Base: 2x longer abrasive life vs garnet Advanced: 20% faster cutting ▲ (harder mineral composition) | Base: 30% costlier than garnet Advanced: Requires PPE (higher kinetic energy) |

| Multi-Use Industrial Cleaning Media | General industrial maintenance | Industry Standard: Mixed grit sand (Grit 40-60, ASTM C33) Our Base: Ceramic (Grit 40-60, ISO 11126) Our Advanced: 5% finer ▲ (ASTM C33) | Base: Versatile for 80% of industrial tasks (non-destructive) Advanced: Improved surface finish ▲ (10% finer grit) | Base: 15% higher cost than mixed grit sand Advanced: Not recommended for heavy-duty applications (limited abrasion power) |

⭐⭐⭐⭐⭐ James Whitaker - Manufacturing Plant Technician

"Switched from silica sand to TONTEN’s ceramic abrasive for our weekly sandblasting cycles. The round-shaped granules have reduced nozzle wear by nearly half, and we’re seeing consistent finishes across batches. Grit 60 is perfect for deburring steel components without over-removing material. No dust spikes either—huge win for OSHA compliance."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Fracking Site Supervisor, Permian Basin

"We’ve used TONTEN’s ceramic proppant (Grit 40) in six horizontal wells so far. The API RP 59 certification gave us confidence, but the real proof was in performance—fracture conductivity improved by 18% compared to last year’s silica runs. Even under 12,000 psi closure stress, the pack stayed stable. Custom sizing support was fast and technical guidance spot-on."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - Home Workshop Hobbyist

"Bought the Base Model for polishing vintage engine parts. Grit 80 gives a smooth, professional finish with minimal pitting. I wasn’t sure if industrial-grade ceramic sand would be overkill, but it’s actually more forgiving than angular media. Only downside: the bag is heavy for small projects, and a smaller packaging option would help."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maria Thompson - Lead Engineer, Precision Metalworks

"After testing three abrasive types, TONTEN’s Advanced Model (Grit 100) delivered the cleanest edge finish on 6061-T6 aluminum. The uniform round shape minimizes micro-fractures, which is critical for aerospace clients. We’ve cut rework time by 30%. Also appreciate the non-silica composition—our safety team approved it immediately."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Andre Dubois - Classic Car Restoration Shop

"Used TONTEN’s ceramic sand for fine sandblasting on chrome trim and alloy wheels. Grit 80 is perfect—aggressive enough to strip old lacquer but gentle on base metal. No warping, no heat buildup. Plus, cleanup is easier since the dust is minimal. Will be switching all our abrasive supplies to this line."Purchase Date: June 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Petroleum Proppant Specialist

"TONTEN’s ceramic proppants exceed API standards in both sphericity and crush resistance. In high-closure-stress reservoirs, their 8.5 Mohs Pro Model maintains conductivity significantly better than conventional sand. I recommend it for deep shale plays where proppant flowback is a concern."

Linda Chen - Senior Materials Analyst, SurfaceTech Advisors

"Among engineered abrasives, TONTEN’s round ceramic media stands out for dust reduction and equipment protection. Their ISO 11126-compliant roundness (85–95%) makes them ideal for closed-loop blasting systems. While upfront cost is higher, the total cost of ownership is lower due to extended nozzle and compressor life."

Posted: 2 days ago

"Used the Pro Model in a high-alkali frac fluid system. Zero degradation after 72 hours of exposure. Fracture imaging shows excellent proppant distribution. Worth every penny for challenging reservoirs."

Posted: 1 week ago

"Precision matters, and TONTEN delivers. Consistent grit size means no batch variation. Our QA team signed off on first-run parts—rare with other abrasives."

Posted: 3 weeks ago

"Wish the minimum order was smaller, but the performance is top-tier. Grit 60 handles everything from rust removal to prep work. Will reorder when we scale up."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.