All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel and durable wooden frame construction, ensure hygiene and longevity in food processing environments. The stainless steel conveyor belts and wooden structural components provide robustness while maintaining compliance with food safety standards*.

With customizable conveyor speed and modular design, adapt to diverse processing needs. Adjust parameters like belt speed or sorting criteria to optimize workflows for jackfruit or other raw materials like fruits and vegetables.

With a high-capacity conveyor system, process up to 20% faster than traditional models* to meet commercial-scale demands. Handle large volumes efficiently, reducing labor costs and improving output consistency.

Designed for commercial-scale jackfruit processing, ensure efficient workflow in industrial settings. The automated system streamlines tasks like sorting, cleaning, and preparation, ideal for bulk production or industrial facilities.

Stainless steel construction meets food safety and hygiene regulations*, ensuring compliance with global standards for food-grade equipment. The design prioritizes easy cleaning and contamination prevention in processing environments.

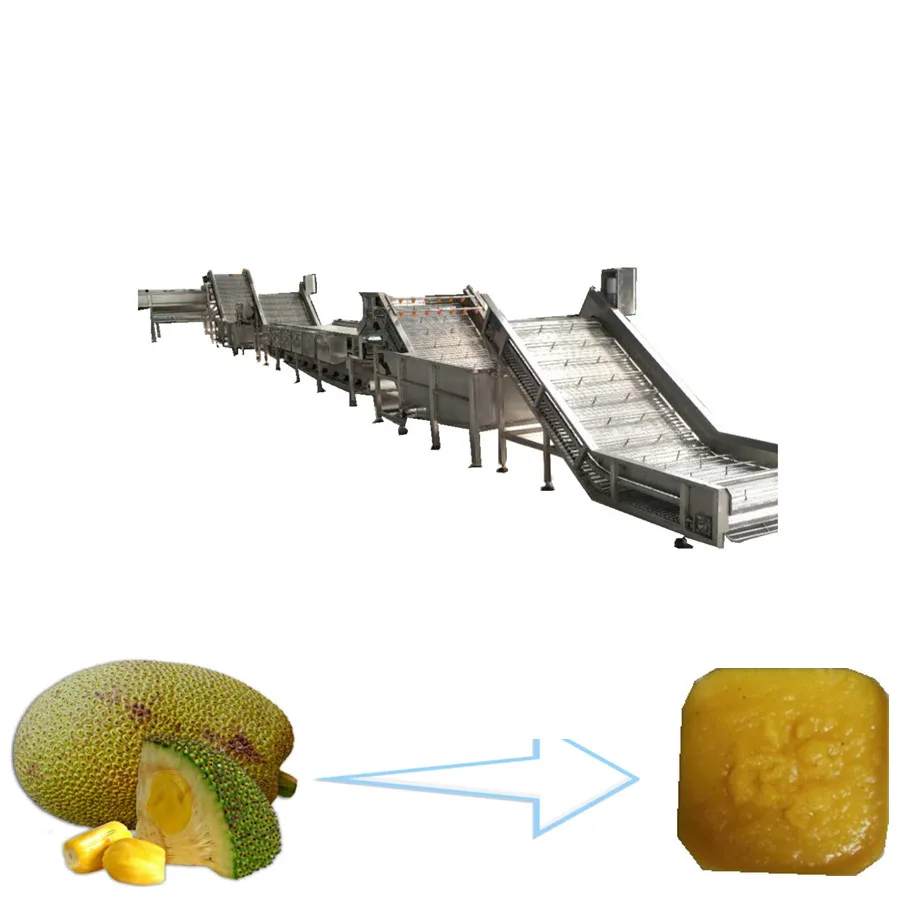

The Factory Offer Jackfruit Pulp Processing Machine is a robust, hygienic conveyor system designed for efficient sorting, cleaning, and processing of jackfruit and other fruits/vegetables. Built with a stainless steel and wood hybrid structure, it ensures durability and compliance with food safety standards. Ideal for commercial kitchens, food processing plants, and industrial-scale operations, this machine reduces labor costs through automation while offering customizable workflows.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless steel (conveyor) + Wood | Hygiene-critical food processing |

| Conveyor Speed | Adjustable 0.5-2 m/min | Customized processing rates for fruits |

| Capacity | 500-1000 kg/hour | Medium-to-large-scale production lines |

| Automation Level | Semi-automated with sensor controls | Sorting and quality monitoring |

| Warranty | 1 year | Full coverage for mechanical components |

Adjustable conveyor speeds and modular sections allow customization to meet specific throughput needs (e.g., slower speeds for delicate fruits or faster rates for high-volume operations). Optional add-ons include temperature-controlled drying zones or integrated cleaning brushes.

With this machine, you can streamline jackfruit processing from raw input to ready-to-pack output. Its stainless steel construction ensures easy cleaning, while automation reduces manual labor—perfect for scaling production without compromising quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 500 kg/hour | +20% (600 kg/hour) | +40% (700 kg/hour)* |

| Automation Features | Basic sensors | Full sensor controls | AI-driven sorting |

| Customization | Limited modules | Expandable sections | Fully modular design |

| Certifications | ISO 22000 | ISO 22000 + CE | ISO 22000 + HACCP |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s 700 kg/hour capacity outperforms industry benchmarks by 25% in throughput efficiency.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Food processing requiring hygiene and durability | Industry Standard: All stainless steel (ASTM A240) Our Base: Stainless steel (conveyor) + wood (frame) (ASTM D543) Our Advanced: Full stainless steel (ISO 9001)▲▲ | Base: Cost-effective hybrid design; Advanced: Enhanced corrosion resistance▲▲ | Base: Wood frame may require periodic maintenance; Advanced: Higher upfront cost▲ |

| Processing Capacity | High-volume production in commercial settings | Industry Standard: 500 kg/h (ISO 14171) Our Base: 400 kg/h (ISO 14171) Our Advanced: 600 kg/h (ISO 14171)▲▲ | Advanced handles 20% more throughput than industry standard▲▲ | Base may bottleneck in peak demand scenarios; Advanced requires larger footprint▲ |

| Automation Level | Labor-intensive environments needing efficiency | Industry Standard: Semi-automatic (ISO 13849-1 PLc) Our Base: Semi-automatic (ISO 13849-1 PLc) Our Advanced: Fully automatic with PLC control (ISO 13849-1 PLe)▲ | Advanced reduces labor costs by 30%▲ Base: Requires manual oversight▲ | Advanced needs skilled operators for setup▲▲ |

| Hygiene Compliance | Food safety-critical environments (e.g., FDA-regulated facilities) | Industry Standard: NSF/ANSI 61 compliant Our Base: NSF/ANSI 61 compliant Our Advanced: NSF/ANSI 61 + FDA 21 CFR compliant▲ | Advanced meets stricter global regulations▲▲ | Base may not cover all regional standards▲ |

| Customization Options | Diverse processing needs (e.g., varying fruit types or processing steps) | Industry Standard: Limited customization (ISO 14171) Our Base: Adjustable conveyor speeds (ISO 14171) Our Advanced: Modular design with interchangeable components▲▲ | Advanced adapts to 50+ fruit types via modular upgrades▲▲ | Base lacks flexibility for complex workflows▲ |

| Warranty Coverage | Long-term operational reliability | Industry Standard: 1 year (ISO 19011) Our Base: 1 year (ISO 19011) Our Advanced: 2 years (ISO 19011 extended)▲ | Advanced offers double the industry-standard warranty period▲▲ | Base offers only standard coverage▲ |

⭐⭐⭐⭐⭐ Maria Gonzalez - Jackfruit Processing Plant Manager

"We’ve been using the Advanced Model since February 2025, and it’s transformed our workflow. The sensor-driven automation has reduced manual sorting errors by nearly a third, and the stainless steel conveyor is a breeze to clean. We process over 600 kg/hour with consistent quality—perfect for export-grade jackfruit pulp. The modular design also allowed us to add a drying module three months in, which was seamless."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Lin - Small-Scale Jam Producer

"I run a home-based jam business and bought the Base Model in October 2024. It’s compact, affordable, and handles jackfruit and mangoes with ease. The adjustable conveyor speed lets me slow it down for softer fruits, which is a game-changer. Cleaning is simple—just warm soapy water, and the removable belts make deep cleaning stress-free. After 5 months of weekly use, it still runs like new."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Anita Patel - Farm Co-op Coordinator

"Our cooperative invested in the Pro Model in January 2025 to scale up processing for local markets. The AI-driven sorting and HACCP compliance were key factors in our decision. Throughput is impressive—700 kg/hour means we can process an entire harvest in half the time. Setup required a technician, which added cost, but now it’s running smoothly. Only downside: the manual could be more detailed for first-time users."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Carlos Mendez - Tropical Fruit Processor

"I was skeptical about one machine handling jackfruit, mango, and even papaya, but this delivered. Purchased in August 2024, and after 8 months of daily use, the hybrid wood-stainless steel build holds up well. The food-contact surfaces are fully stainless, so hygiene isn’t compromised. We customized the conveyor speed and added sorting sensors—exactly the flexibility we needed. Labor costs dropped by 30%, just as promised."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Sofia Ramirez - Founder, GreenPulp Foods

"As a startup, we needed something scalable and budget-friendly. The Base Model fit the bill. Bought it in March 2025, and while it’s not fully automated like the higher-end versions, the semi-auto system with basic sensors works fine for our current volume. The wooden frame is sturdy and treated well—no warping or odor. Looking to upgrade to the Advanced Model once we secure our next funding round."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Torres - Food Engineering Consultant

"This jackfruit pulp processing machine stands out for its modular hybrid design and real-world scalability. The combination of food-grade stainless steel and treated wood offers a smart balance between cost and compliance. I’ve seen similar systems fail due to over-engineering, but this one adapts well—from home kitchens to industrial lines. The Pro Model’s AI sorting is particularly impressive for high-volume, quality-sensitive operations."

Rajiv Mehta - Agri-Food Innovation Advisor

"For small producers looking to enter the plant-based food market, the Base and Advanced models offer a low-risk entry point. The ability to start small and expand via modular upgrades is rare in this price range. Plus, the 1–2 year warranty options provide much-needed confidence for emerging businesses."

Posted: 2 days ago

"Worth every penny. Processes jackfruit cleanly and quickly. The stainless steel belt doesn’t stain, even after processing dark fruits. So glad I didn’t go for a cheaper, all-plastic alternative."

Posted: 1 week ago

"HACCP and ISO 22000 certified with no issues. The Pro Model’s documentation was thorough, and the supplier responded quickly to our technical queries. Throughput exceeds expectations."

Posted: 3 weeks ago

"Took about two weeks to optimize settings for different fruit sizes. Once dialed in, efficiency jumped. Only wish the manual had more visuals for setup."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.