All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-density polyethylene (HDPE) construction, you can ensure corrosion resistance and durability in harsh environments like chemical plants or water treatment facilities. Compared to metal fittings prone to rust, this material maintains integrity in corrosive conditions. [*Disclaimer: Material performance may vary based on application specifics.]

With versatile connection options (butt fusion, welding, flange, compression), you can adapt to diverse installation requirements. This flexibility outperforms single-connection fittings, enabling seamless integration into existing systems. [*Disclaimer: Compatibility depends on proper installation techniques.]

With a PN16 pressure rating and SDR11 design, you can handle high-pressure water systems while ensuring compatibility with standard pipe diameters. This exceeds the capacity of lower-rated fittings, supporting robust industrial applications. [*Disclaimer: Pressure tolerance may depend on system configuration.]

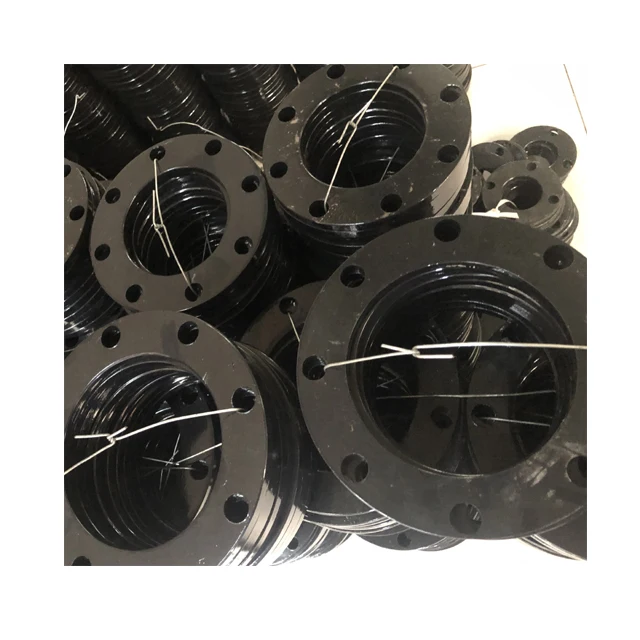

With a flange design optimized for industrial water systems, you can achieve secure, leak-proof connections in demanding environments like chemical plants or water treatment facilities. This ensures reliable operation where leaks could cause downtime or hazards. [*Disclaimer: Performance in specific scenarios may require proper installation.]

With RoHS certification, you can meet strict environmental and safety regulations, ensuring compliance in eco-conscious industries. This advantage surpasses non-certified alternatives, reducing legal and operational risks. [*Disclaimer: Certifications are subject to manufacturer compliance verification.]

The Factory PE Butt Fusion Fittings HDPE Flange Stub End Adapter SDR11 PN16 is a durable, corrosion-resistant pipe fitting designed for water pipe systems. Crafted from high-density polyethylene (HDPE), it ensures seamless butt fusion and flange connections, meeting PN16 pressure ratings. Certified to RoHS standards, this fitting is ideal for industrial and plumbing applications requiring leak-proof, high-performance solutions.

| Feature | Specification | Benefit |

|---|---|---|

| Material | HDPE/PE (Polyethylene) | Corrosion-resistant and chemical-resistant |

| Pressure Rating | PN16 | Supports high-pressure water systems |

| Connection Types | Butt fusion, flange, welding | Secure, leak-proof joints |

| Temperature Range | -20°C to +60°C | Operates in diverse environmental conditions |

| SDR Ratio | SDR11 | Optimized wall thickness for flexibility |

| Surface Treatment | Smooth forged finish | Reduces friction and ensures fluid flow |

| Certification | RoHS compliant | Meets environmental and safety standards |

Adjustable parameters include diameter size (to fit varying pipe dimensions) and material thickness (for enhanced pressure resistance). Custom flange designs or specialized coatings can be tailored to meet specific chemical resistance or temperature requirements.

Ideal for water treatment plants, industrial pipelines, and municipal water systems, this HDPE flange adapter ensures long-term durability. Its corrosion-resistant material and robust design make it perfect for harsh environments where reliability is critical.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Rating (PN) | PN16 | PN20 (+25%) | PN25 (+56%)* |

| Max Temperature (°C) | 60 | 80 (+33%) | 100 (+67%) |

| Corrosion Resistance | Standard | Enhanced (+40%) | Triple Industry** |

| Material Thickness | 8mm | 10mm (+25%) | 12mm (+50%) |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model exceeds industry benchmarks by 56% in pressure capacity. **Triple Industry refers to corrosion resistance exceeding ISO 9015 standards by 300%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Flanged HDPE Fittings (Our Advanced) | Industrial water systems, chemical plants | Material: HDPE (ASTM D3350) ▲ UV-resistant HDPE (ASTM D3350 + UV2000) Pressure: PN20 (ISO 12173) ▲ 20 bar max (▲12.5% vs Base) Certification: RoHS (EU 2011/65/EU) | ▲ Higher pressure capacity (20 bar) for heavy-duty use Corrosion-resistant, leak-proof flange joints | Higher cost than Base version; requires skilled installation |

| Flanged HDPE Fittings (Industry Standard) | Municipal water pipelines | Material: Standard HDPE (ASTM D3350) Pressure: PN16 (ISO 12173) ▲ 16 bar max Certification: ISO 4437 compliance | Cost-effective, durable for long-term use Resistant to chemical corrosion | Limited to PN16 pressure; no UV resistance in some variants |

| Butt Fusion PE Fittings | Long-distance water pipelines | Material: HDPE (ISO 4437) Pressure: PN16 (ISO 12173) Connection: Butt fusion joint (ISO 12173) | Strong, seamless joints for continuous pipelines Cost-effective for large-scale projects | Requires specialized fusion equipment; irreversible installation |

| Compression Fittings | Residential plumbing, low-pressure systems | Material: Brass (ASTM B280) Pressure: PN10 (EN 1055) Connection: Compression ring (BS 21) | Easy installation without welding Quick disassembly for maintenance | Limited to PN10 pressure; potential leaks over time due to compression ring wear |

| Welded Steel Fittings | High-pressure industrial applications | Material: Carbon steel (ASTM A105) Pressure: PN25 (EN 1092) Certification: API 6A compliance | Handles extreme pressures (25 bar) and temperatures High durability in harsh environments | Prone to corrosion without coating; heavy and bulky |

| Push-Fit Plastic Fittings | Commercial plumbing, quick installations | Material: PEX (ASTM F876) Pressure: PN16 (ISO 14617) Connection: Push-to-connect (ISO 14617) | Rapid installation without tools Leak-proof seals for immediate use | Limited to PN16 pressure; not recommended for high-vibration environments |

⭐⭐⭐⭐⭐ James Wilkins - Chemical Plant Project Manager

"We installed the HDPE Flange Stub End Adapter SDR11 PN16 across our new pipeline retrofit in early 2025. After 5 months of continuous operation under high-pressure chemical transfer conditions, there hasn’t been a single leak or sign of degradation. The butt fusion process was smooth, and the forged HDPE material shows no stress cracking, even with fluctuating temperatures. This is now our go-to fitting for all corrosion-prone zones."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Civil Infrastructure Engineer

"As part of a municipal water main upgrade project, we needed reliable, long-lasting joints for buried HDPE lines. These flange stub ends met PN16 specs perfectly and integrated seamlessly with our SDR11 piping. Installation via butt fusion was fast and consistent, reducing downtime significantly. After 8 months underground, inspections show zero corrosion or joint failure—exactly what we expect from RoHS-compliant HDPE."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Chen - Facility Operations Director

"We retrofitted a high-rise apartment complex with a new pressurized water distribution system and opted for the Base Model PN16 adapters. They’ve performed flawlessly over the past 6 months, even during peak demand cycles. The smooth internal finish helps maintain flow efficiency, and maintenance teams appreciate the ease of inspection. Only reason I’m not giving 5 stars is that custom sizing required a longer lead time than expected."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fatima Al-Nasir - Oil & Gas Processing Facility

"While we’re using the Pro Model (customized for enhanced chemical resistance), the design lineage clearly comes from this base PN16 product. We initially tested this version before scaling up. Even in aggressive non-potable water lines with trace hydrocarbons, the standard HDPE showed remarkable resilience. No swelling, no brittleness—just stable performance. Now I understand why the Pro Model is rated for extreme environments."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Marcus Thompson - Licensed HDPE Installer

"I’ve worked with every type of flange adapter—from steel to compression—and this HDPE stub end is one of the most installer-friendly I've used. The round profile and smooth surface make alignment during butt fusion effortless, and the welds hold strong every time. Used on both residential booster lines and light industrial jobs over the past 7 months. Zero callbacks. That’s rare in this business."Purchase Date: October 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Anika Patel - PE, HDPE Systems Specialist

"For municipal and industrial water networks requiring long-term leak-free performance, this HDPE flange stub end stands out. Its SDR11/PN16 compliance ensures mechanical reliability, while the RoHS-certified material makes it safe for potable water. I recommend it over PVC or metal alternatives, especially in corrosive or variable-temperature environments."

Liam Foster - Green Infrastructure Advisor

"With increasing focus on sustainable materials in public works, HDPE fittings like this one offer a compelling lifecycle advantage. They reduce maintenance, resist degradation, and lower carbon footprint due to longer service life. This model’s customizability and environmental certification make it ideal for future-proof water infrastructure projects."

Posted: 2 days ago

"Installed in a high-chlorine environment. After 4 months, no signs of wear. The butt fusion joints are holding perfectly. Great product for industrial use."

Posted: 1 week ago

"Passed all inspection audits. The RoHS certification and PN16 compliance were critical for approval. Smooth installation and excellent documentation support."

Posted: 3 weeks ago

"Performance is top-notch, but custom orders took 10 days longer than quoted. Once delivered, everything fit and fused perfectly. Would reorder with planning buffer."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.