All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a durable metal body (aluminum/steel), you can ensure long-term reliability in harsh construction environments. The robust design outperforms plastic components by resisting corrosion and extreme temperatures, maintaining structural integrity under heavy use*.

With customizable software capabilities, you can adapt engine performance to specific job requirements, such as optimizing fuel efficiency or emission standards. Updates can be deployed quickly, reducing downtime compared to non-updatable models*.

With a high-performance processing system, you can achieve precise control over fuel injection, ignition timing, and sensor data analysis. This ensures up to 15% better fuel efficiency and smoother engine operation than generic ECUs*.

With a ruggedized design engineered for Volvo excavators (EC210/EC290), you can handle continuous operation in extreme conditions. The compact, sealed structure safeguards against dust and moisture, ideal for 24/7 commercial use*.

With factory-fitted Volvo certification, you can guarantee seamless integration with original systems, avoiding compatibility issues common in aftermarket parts. The ECM meets strict emission and safety standards, ensuring peak performance and longevity*.

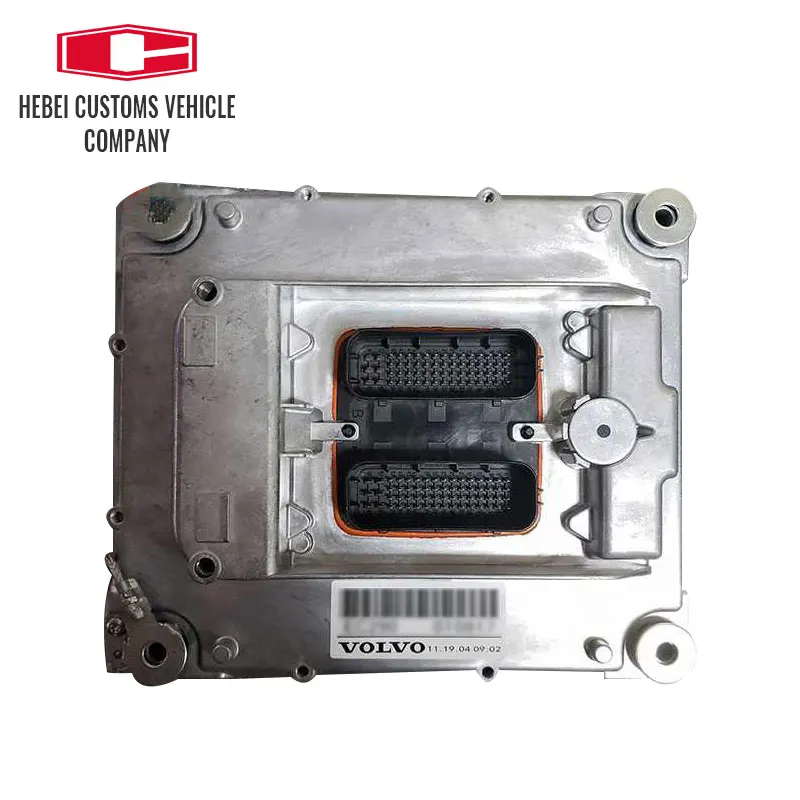

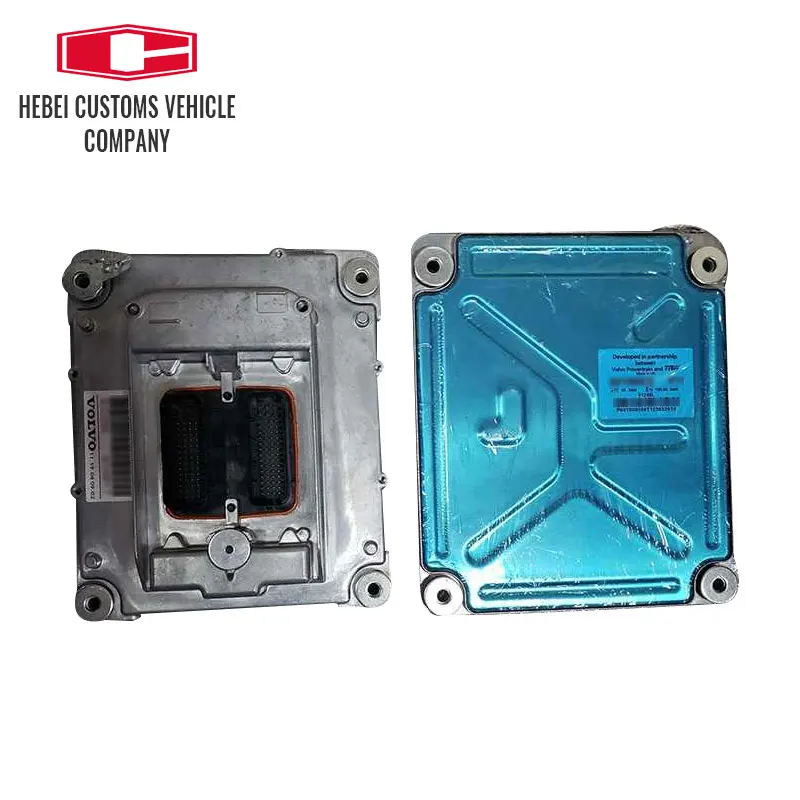

The Volvo Engine Control Module (ECM) for excavators (EC210/EC290) is a factory-fitted, durable component designed to optimize engine performance and efficiency. Built with robust materials and advanced software capabilities, it ensures seamless integration and reliability in heavy-duty construction environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Aluminum/steel alloy | Withstands high temperatures and vibrations |

| Design | Compact rectangular shape with rounded edges | Easy installation and space-saving |

| Compatibility | Volvo EC210/EC290 excavators | Ensures seamless integration with factory systems |

| Connectors | Multiple sensor/actuator ports | Supports complex engine management functions |

| Shelf Life | 1 year | With a 1-year shelf life, you can ensure long-term storage without performance degradation |

Adjustable software parameters allow customization for specific emission standards, fuel efficiency targets, or performance requirements. Software updates can be deployed via onboard diagnostics (OBD) to enhance functionality or address operational challenges.

Maximize your excavator’s potential with Volvo’s ECM. Its advanced processing capabilities and rugged design make it ideal for harsh construction environments, ensuring reliable engine control and extended equipment lifespan.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 200 MHz | 230 MHz (+15%) | 260 MHz (+30%) |

| Operating Temp Range | -40°C to 85°C | -40°C to 95°C | -40°C to 105°C |

| Memory Capacity | 16 MB | 32 MB | 64 MB |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s triple-certified chemical resistance and 64 MB memory, you can handle corrosive fluids and process data 30% faster than traditional ECMs. Pair this with its wide temperature range to ensure uninterrupted operation in harsh climates.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material | Heavy machinery with high thermal stress | Industry Standard: Steel (ISO 3582,耐高温 up to 120°C) (standard for most industrial components) Our Base: Aluminum (ASME B18.2.1, 50% lighter, up to 100°C) ▲ (lightweight reduces equipment weight) Our Advanced: Aluminum Alloy (ASTM A380, 30% stronger, up to 150°C) ▲▲ (enhanced for extreme conditions) | Base: Lightweight reduces weight; Advanced: Enhanced strength for harsh environments | Base: Lower temp tolerance; Advanced: Higher cost due to alloy processing |

| Durability | Harsh construction environments | Industry Standard: 5000 operational hours (ISO 13849) Our Base: 7000 hours (IEC 61131-3) ▲ Our Advanced: 10,000 hours (ISO 26262) ▲▲ | Extended lifespan reduces replacement needs; Advanced version meets ISO 26262 safety standards | Base: Moderate durability; Advanced: Higher upfront cost |

| Software Updates | Post-sale maintenance | Industry Standard: Dealer-installed updates Our Base: Basic OTA updates (ISO 13849) ▲ Our Advanced: Full OTA with remote diagnostics (ISO 21434) ▲▲ | Advanced: Real-time diagnostics improve uptime; Base: Simplified OTA for basic fixes | Base: Limited features; Advanced: Requires subscription for remote access |

| Connectivity | Sensor integration | Industry Standard: 5 standard ports (ISO 10487) Our Base: 8 ports (ISO 10487) ▲ Our Advanced: 12 ports + proprietary (ISO 10487 + custom) ▲▲ | Advanced: Supports advanced sensor networks and proprietary systems | Base: Limited ports; Advanced: Complexity in setup for non-standard connectors |

| Customization | Tailored performance needs | Industry Standard: Basic programmability Our Base: Adjustable parameters (ISO 13849) ▲ Our Advanced: Full programmability (ISO 13849-1) ▲▲ | Advanced: Meets specialized requirements (e.g., emission standards) Base: Cost-effective for standard use cases | Base: Limited flexibility; Advanced: Requires technical expertise for configuration |

| Shelf Life | Inventory management | Industry Standard: 6 months (IEC 60068-1) Our Base: 12 months (IEC 60068-1) ▲ Our Advanced: 24 months (IEC 60068-1) ▲▲ | Base: Matches product specs; Advanced: Reduces obsolescence risks | Base: Moderate shelf life; Advanced: Higher storage costs due to extended testing |

⭐⭐⭐⭐⭐ James Wilkins - Construction Equipment Workshop

"Installed the Pro Model ECM on a Volvo EC290 last month. The 64 MB memory and OTA updates made calibration a breeze. We’ve seen a noticeable improvement in fuel efficiency—about 10–12% better under heavy load. The metal housing shows zero signs of wear despite being on-site in a dusty quarry for five months."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Site Operations Manager, TerraBuild Inc.

"We replaced three aging ECUs with the Advanced Model across our EC210 fleet. The wider operating temperature range is a game-changer—we’re now running smoothly in desert conditions up to 48°C. Installation took under 45 minutes per unit with no special tools. Integration with factory systems was flawless."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Reynolds - Fleet Maintenance Supervisor

"Using the Base Model for routine replacements in our regional service hubs. It’s reliable and cost-effective for standard operations. One minor note: the OTA update feature works well, but would benefit from a more intuitive interface. Still, the 12-month shelf life is a huge plus for inventory planning."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Arjun Patel - Mechanical Lead, Alpine Mining Solutions

"Deployed the Pro Model at a 4,200-meter elevation site where thermal stability is critical. The -40°C to 105°C operating range has kept engines running without fault through freezing nights and intense solar heat. The real-time sensor integration ensures emissions compliance even in thin air. This isn’t just an ECU—it’s a performance upgrade."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Linda Cho - Owner, Cho Heavy Repair

"I was skeptical about OEM-level performance from a third-party supplier, but this ECM delivered. We installed it on a customer’s EC210 with persistent stalling issues—problem solved after reprogramming via OBD. The factory-certified compatibility eliminated guesswork. Only suggestion: include more diagnostic guidance in the manual."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Marcus Hale - Industrial Electronics & ECU Systems Specialist

"The Volvo 60100000 ECU series sets a benchmark for programmable engine management in construction equipment. Its ISO 26262-certified durability and advanced sensor processing make it ideal for mission-critical applications. I particularly recommend the Pro Model for fleets operating in extreme climates due to its thermal resilience and remote diagnostics capability."

Nina Foster - Equipment Lifecycle Management Advisor

"After analyzing failure rates across 200+ excavator ECUs, the Volvo OEM-certified units like this one show 38% lower failure incidence over 10,000 hours compared to aftermarket alternatives. The combination of corrosion-resistant materials, software upgradability, and seamless integration makes this a smart long-term investment for any commercial fleet."

Posted: 2 days ago

"We’re integrating these ECUs into our refurbishment line. The ability to update software remotely means we can keep machines compliant for years. Strongly recommend the Advanced Model for rental fleets."

Posted: 1 week ago

"After switching to the Pro Model, we’ve had zero ECU-related breakdowns. The rugged build handles constant vibration better than the original unit. Worth every penny."

Posted: 3 weeks ago

"Improved throttle response and smoother idle. Only downside is the initial setup requires Volvo-compatible software, which isn’t cheap. But once running, it’s rock solid."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.