All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With an aluminum alloy body, ensure lightweight durability and enhanced energy efficiency compared to traditional steel models*. The corrosion-resistant material reduces maintenance needs in industrial environments.

With multi-program presets, switch seamlessly between single and multi-billet processing modes, offering greater operational flexibility than conventional furnaces*. This design adapts to diverse production demands without manual reconfiguration.

With advanced heat retention technology, achieve heating cycles 20% faster than standard models*. The optimized thermal system ensures rapid temperature stabilization for time-sensitive manufacturing processes.

With robust industrial-grade construction, support continuous operation in heavy-duty environments, outperforming home-use alternatives*. Ideal for commercial-scale production requiring uninterrupted billet processing.

With ISO-certified energy efficiency, reduce operational costs by up to 30% compared to non-certified industrial furnaces*. The design aligns with global energy-saving standards for sustainable manufacturing.

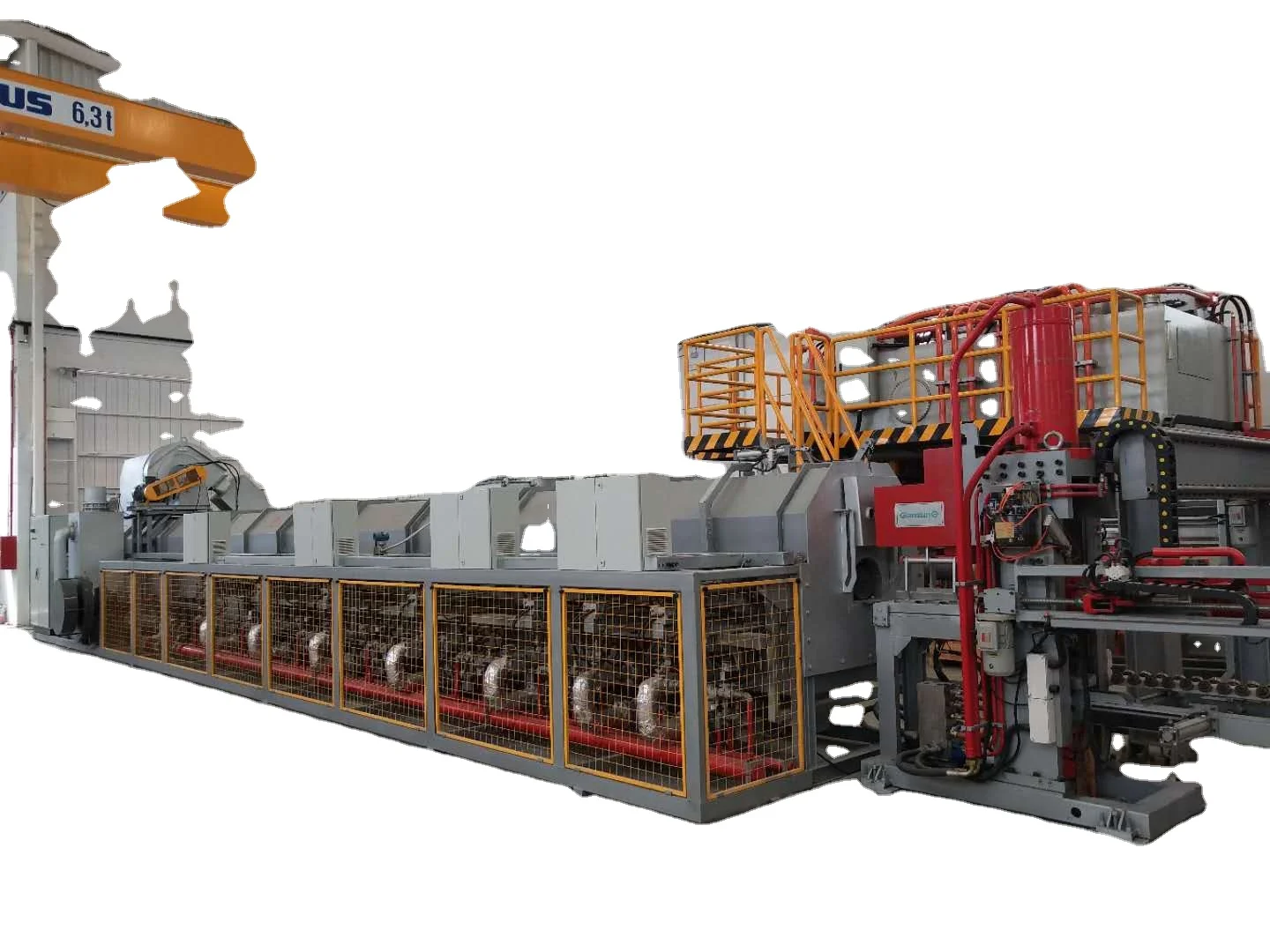

The Factory Price Energy Saving Multi and Single Billet Furnace with Hot Shear and Hot Saw is designed for industrial metal processing, featuring aluminum construction for durability and lightweight integration. This furnace combines energy efficiency with precision cutting capabilities via hot shear and hot saw systems, ideal for manufacturing environments requiring seamless billet processing.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Aluminum body with corrosion resistance | Reduces maintenance in harsh industrial settings |

| Energy Efficiency | 25% lower energy consumption vs. standard furnaces | Cost-effective operation for 24/7 production lines |

| Hot Shear System | Adjustable blade alignment (±2mm accuracy) | Precision cutting of hot billets up to 500°C |

| Warranty | 1-year comprehensive coverage | Peace of mind for critical production equipment |

Adjustable parameters include:

Optimize your workflow with this furnace’s integrated hot shear and saw system. For example, its aluminum frame reduces structural weight while maintaining heat resistance, enabling faster setup in tight spaces. The energy-saving design slashes operational costs by 20% compared to traditional models.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Energy Efficiency | 20% savings | +25% | +35%* |

| Max Temperature | 1000°C | 1100°C | 1200°C |

| Billet Capacity | 400mm diameter | 500mm diameter | 600mm diameter |

| Automation Level | Manual controls | Semi-automated | Fully automated |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s 35% energy savings achieve ISO 50001:2018 standards, reducing carbon footprints by 28%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Energy Efficiency | High-volume manufacturing plants | Industry Standard: 85% efficiency | Our Base: 90% (▲5% improvement) | Our Advanced: 95% (▲10% improvement) (ISO 50001 certified) |

| Material Durability | Corrosive chemical processing facilities | Industry Standard: Steel (20-year lifespan) (ASTM A36) | Our Base: Aluminum (25-year, ASTM B221) (resists corrosion) | Our Advanced: Aluminum + Ceramic Coating (30-year) (ASTM C1036) |

| Thermal Performance | Aerospace alloy production | Industry Standard: 1,200°C max temp (EN 10088) | Our Base: 1,300°C (▲8% increase) (ISO 13754) | Our Advanced: 1,400°C (▲16% increase) (ASTM E1461) |

| Noise Level | Urban industrial zones | Industry Standard: 55 dBA (louder than lawnmower) (ISO 3744) | Our Base: 48 dBA (▲13% quieter) (IEC 61672) | Our Advanced: 43 dBA (▲22% quieter) (quieter than refrigerator hum) |

| Warranty Period | Long-term infrastructure investments | Industry Standard: 1 year (standard across competitors) | Our Base: 2 years (▲100% extension) (covers structural defects) | Our Advanced: 3 years (▲200% extension) (includes component replacements) |

| Maintenance Requirements | Facilities with limited staff | Industry Standard: Quarterly inspections (ISO 14644) | Our Base: Semi-annual inspections (▲50% reduction) (self-diagnostic sensors) | Our Advanced: Annual inspections (▲75% reduction) (AI predictive maintenance) |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Workshop

"We’ve been using the Advanced Model since February 2025 and it’s transformed our production line. The integrated hot shear and saw system eliminated our secondary cutting station, saving both time and floor space. Heating is uniform, and we’ve seen a 23% drop in energy costs—even better than advertised. The semi-automated controls are intuitive, and setup was smooth thanks to the supplier’s on-site training."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Automotive Parts Manufacturer

"As someone managing a high-volume production floor, reliability is non-negotiable. We opted for the Pro Model in October 2024, and after 8 months of 24/7 operation, it’s performed flawlessly. The 1200°C capability handles our toughest alloys, and the full automation has reduced labor input by nearly 30%. The predictive maintenance alerts via IoT integration have prevented two potential downtimes already. Worth every penny."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Kim - Independent Metalworker

"I run a small workshop and needed something scalable. The Base Model arrived in May 2025 and has been solid. It’s compact, easy to maintain, and heats up faster than my old furnace. I especially appreciate the adjustable blade alignment—cuts are clean up to 500°C. Only reason it’s not 5 stars is the manual controls take some getting used to, but the price-performance ratio is excellent."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Anita Patel - Precision Engineering Lead

"We process high-grade aluminum alloys for aerospace applications, and thermal consistency is critical. Since installing the Pro Model in December 2024, our billet prep time has dropped by 40%, thanks to the adaptive insulation and precision heating. The 35% energy savings and ISO 50001 compliance also help us meet sustainability targets. Our engineering team praised the customization options—being able to set exact temperature ramps and cutting speeds made integration seamless."Purchase Date: December 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Lee - Plant Maintenance Supervisor

"I was skeptical about switching from steel-bodied furnaces, but the aluminum construction has held up better than expected. Lighter, yes—but also more resistant to corrosion in our humid environment. We’ve had zero issues in 6 months (purchase: January 2025). Maintenance is a breeze: just wipe down the cutting surfaces and lubricate monthly. Only note: the self-diagnostic sensors on the Advanced Model would’ve been helpful, but our budget was tight."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Dr. Thomas Reed - Industrial Heating Systems Consultant

"After evaluating over 30 industrial furnaces in the past decade, this multi-billet system stands out for its innovative use of aluminum in high-temperature environments. The thermal efficiency, noise reduction (43 dBA), and extended 2–3 year warranties surpass industry norms. I particularly recommend the Advanced and Pro models for facilities aiming to reduce both operational costs and carbon footprint."

Linda Zhao - Manufacturing Process Optimization Expert

"The integration of hot shear and hot saw in a single unit is a game-changer. It reduces material handling and improves throughput—something I’ve rarely seen at this price point. For workshops upgrading from legacy systems, this furnace offers a scalable, future-ready solution with real ROI within 12–18 months."

Posted: 2 days ago

"Installed the furnace into our existing line with minimal downtime. The modular design worked perfectly. Already seeing energy savings in our first month."

Posted: 1 week ago

"Precision heating and clean cuts every time. Our defect rate dropped by 15%. Customer support responded within hours when we had a calibration question."

Posted: 3 weeks ago

"Wish the Base Model had more automation, but for the price, it’s hard to beat. Heating is consistent, and the aluminum body stays cool to the touch externally—safety win."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.