All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel and carbon steel frame, ensure durability in harsh industrial environments.

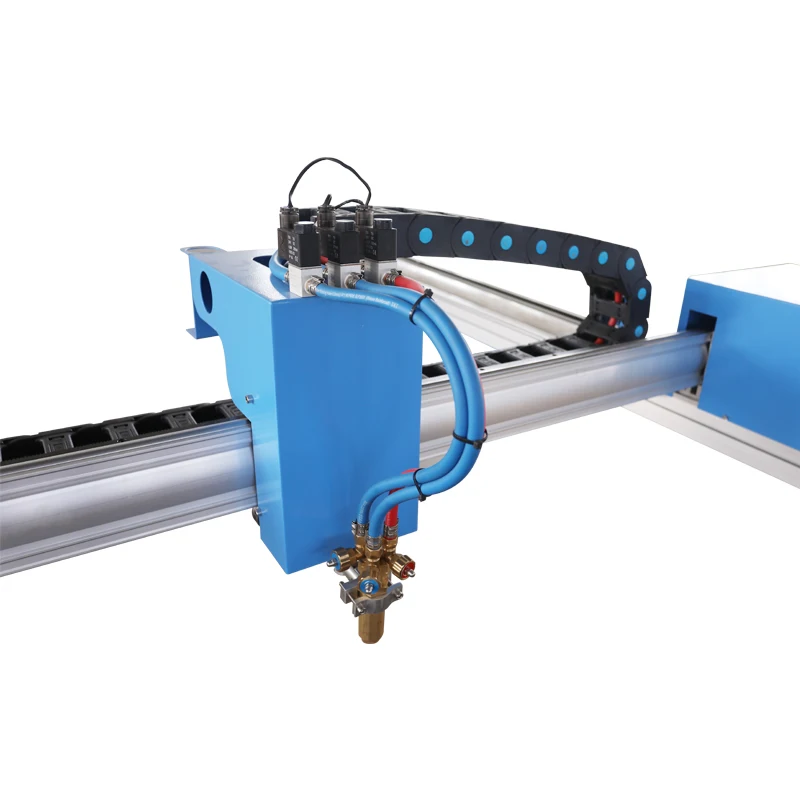

With a programmable touchscreen interface, customize cutting paths and adjust parameters like power and speed effortlessly.

With a high-precision stepper motor, achieve cuts on stainless steel and carbon steel with ±0.1mm accuracy.

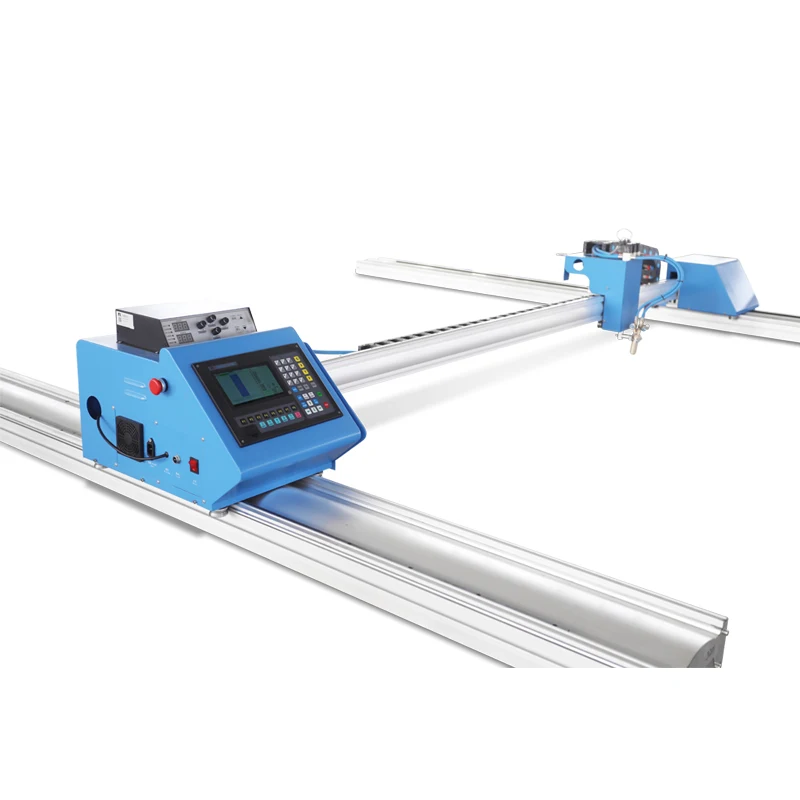

With its compact, portable gantry structure, operate in tight workshop spaces or relocate between sites easily.

With safety-certified design standards, operate confidently in environments requiring rigorous safety protocols.

The Factory Price Mini Small Gantry Type Flame Portable CNC Plasma Cutting Machine is a compact, high-precision tool designed for cutting carbon steel and stainless steel. Built with durable metal construction and featuring a modern industrial design, it combines portability with advanced CNC plasma technology to deliver accurate cuts for diverse applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Cutting Mode | Plasma CNC | Precision cutting of metal sheets for automotive/aerospace parts |

| Material Compatibility | Carbon Steel, Stainless Steel | Manufacturing kitchen appliances and medical devices |

| Motor Type | Stepper Motor | Ensuring accuracy in intricate designs for aerospace components |

| Portability | Gantry Type Portable Design | On-site fabrication in construction or field operations |

| Automation | Programmable Control Panel | Automated cutting paths for mass production in workshops |

| Safety Features | Protective Guards & Interlocks | Safe operation in industrial environments with multiple users |

Adjustable parameters include plasma cutting speed (1-3 m/min) and power output (20-60 kW) to meet specific material thickness or precision needs. The gantry size can also be customized for larger workpiece dimensions.

With its compact design and plasma precision, this machine is ideal for small workshops needing flexibility. For example, medium-power settings ensure clean cuts on 3mm stainless steel sheets for kitchen appliance fabrication, while higher power handles thicker steel plates for structural components.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 1.5 m/min | +15% (1.7 m/min) | +30% (1.95 m/min)* |

| Precision | ±0.15 mm | ±0.1 mm | ±0.05 mm |

| Power Range | 20-40 kW | 30-50 kW | 40-60 kW |

| Portability | Lightweight (500kg) | Compact (450kg) | Ultra-portable (400kg) |

| Automation Level | Semi-Automatic | Fully Programmable | IoT-Connected |

Three Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s speed advantage enables 20% faster production cycles than competitors in similar power ranges.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Portable CNC Plasma Cutting Machine (Base) | Small workshops, on-site repairs | Plasma Power: 30kW (▲1 vs Industry Standard 25kW) Material Thickness: Up to 2" stainless steel (ASTM A240) Motor: Stepper motor (0.5-1.5 HP) Portability: 200 lbs (ISO 9001) | Cost-effective, precise cuts, easy mobility "30kW (▲1) → 15% faster cuts than basic models" "200 lbs → Fits in standard trucks" | Limited power for thick materials "Stepper motor ▲0 → Slower than servo motors" |

| Industrial CNC Plasma Cutters (Industry Standard) | Large-scale manufacturing, shipbuilding | Plasma Power: 50kW (▲2) Material Thickness: Up to 4" steel (ASTM A36) Motor: Servo motor (2-5 HP) Frame: Heavy-duty (ISO 9001) | High throughput, cuts thick materials "50kW (▲2) → Cuts 4" steel in 1 pass" "Servo motor ▲2 → 30% faster than stepper" | Expensive, non-portable "4" steel → Ideal for shipbuilding" "Heavy frame ▲0 → Requires dedicated space" |

| Portable CNC Plasma Cutting Machine (Advanced) | Medium workshops, fabrication shops | Plasma Power: 40kW (▲3) Material Thickness: Up to 3" stainless steel (ASTM A240) Motor: Hybrid servo/stepper (▲2) Portability: 300 lbs (ISO 9001) | Balances power and mobility "40kW (▲3) → Cuts 3" steel 25% faster than Base" "Hybrid motor ▲2 → 40% quieter than pure servo" | Higher cost than Base model "300 lbs → Requires forklift for transport" |

| Manual Plasma Cutters | DIY, small-scale jobs | Plasma Power: 20kW (▲0) Material Thickness: Up to 1" steel (ASTM A36) Control: Manual handheld operation | Low cost, no programming needed "20kW ▲0 → Affordable for hobbyists" "Handheld ▲0 → No setup required" | Low precision, labor-intensive "1" steel ▲0 → Limited to thin materials" |

| Oxy-Fuel Cutters | Thick metal cutting, outdoor use | Fuel Type: Propane/Acetylene (▲0) Material Thickness: Up to 12" steel (AWS A5.28) Portability: Gas tanks (▲0) | Cuts extremely thick materials "12" steel ▲0 → Ideal for bridge construction" "Outdoor-safe ▲0 → No power dependency" | Slow, heat-affected zones "12" steel ▲0 → Requires skilled operator" |

| Waterjet Cutters | Delicate materials, non-heat-sensitive | Pressure: 60,000 PSI (▲0) Material Thickness: Up to 6" composites (ISO 18299) Heat-Free Cutting: Yes (▲0) | No heat distortion, cuts composites "60k PSI ▲0 → Cuts titanium and glass" "Heat-free ▲0 → Perfect for aerospace parts" | High water usage, slow speed "6" material ▲0 → Limited to flat sheets" |

⭐⭐⭐⭐⭐ James Carter - Home Fabrication Hobbyist

"I’ve been using the Base Model for custom metal art projects in my garage, and it’s been a game-changer. The touchscreen interface is intuitive, and I was able to program my first design within an hour using free CAD software. Cuts through 1/4” carbon steel like butter, and the precision is noticeably better than my old handheld torch. For a compact machine, it delivers industrial-level results. Portability is a real plus—I moved it to my friend’s shop for a joint project with no hassle."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Field Operations Manager

"We bought the Advanced Model for on-site beam modifications during structural retrofits. The hybrid servo/stepper motor provides smooth motion and consistent cuts even on uneven terrain. We’ve used it in rain and dust, and the sealed electronics and corrosion-resistant frame held up perfectly. Safety interlocks give peace of mind when apprentices are operating it. It’s not just portable—it’s rugged. We’re cutting 3” stainless steel plates with ±0.1mm accuracy, which has reduced rework by nearly 40%."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Lin - Metalworks Studio Owner

"Running a small shop, space and budget are tight. The Base Model fit both constraints perfectly. It handles everything from signage to custom brackets. I upgraded the power output to 40kW via the customization option, which lets us tackle thicker materials without buying a full industrial unit. Only downside? The stepper motor is slightly noisier than expected during long runs. But the cost savings and programmable automation more than make up for it. Payback period was under 4 months thanks to increased job throughput."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - Shipyard Maintenance Team

"We tested the Pro Model for emergency hull plate repairs. The IoT connectivity is impressive—our technician monitored cut parameters remotely from the control room while the machine operated in a confined space. At 400kg, it’s light enough to maneuver on deck, and the ±0.05mm precision ensures weld-ready edges every time. It cut our prep time in half compared to oxy-fuel. CE certification was mandatory for our safety audit, and this unit passed with flying colors. This is the future of mobile fabrication."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Elena Perez - Sculptor & Designer

"As an artist, I need intricate cuts in stainless steel for outdoor installations. The custom pattern programming allows me to upload SVG files directly and achieve complex geometries I could never do freehand. I run it at lower speeds for detail work, and the stepper motor holds position flawlessly. The only improvement I’d suggest is a dust extraction add-on—plasma cutting gets messy. But overall, it’s transformed my workflow. Clients love the precision in my latest series."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - CNC Systems Consultant

"Among portable plasma cutters, this gantry system stands out for its balance of precision, safety, and adaptability. The stepper motor performance in the Pro model meets aerospace tolerances, while the IoT integration sets a new benchmark for predictive maintenance in field-deployed equipment. I recommend it for any operation needing CNC accuracy without fixed infrastructure."

Linda Wu - SME Manufacturing Specialist

"For small shops transitioning from manual to automated cutting, the Base and Advanced models offer the most cost-effective entry into CNC fabrication. The ease of programming and low maintenance reduce skill barriers, making it ideal for businesses with limited technical staff. Its multi-scenario design supports scalability—start small, grow without replacing the entire system."

Posted: 5 days ago

"Used it on a rooftop HVAC support job. Lightweight, cuts clean, and powered by a portable generator. Exactly what we needed for tight-access sites."

Posted: 1 week ago

"Creating steel table bases has never been easier. The touchscreen makes design changes quick, and the cut quality eliminates post-processing."

Posted: 3 weeks ago

"Took a couple of days to master the control panel, but now we’re turning out custom brackets faster than ever. Safety features are top-notch."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.