All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With high-temperature corrosion-resistant quartz glass, maintain structural integrity in extreme environments, outperforming traditional glass and metal alternatives*. The quartz material withstands harsh chemicals and temperatures up to 1400°C, ensuring durability in demanding applications.

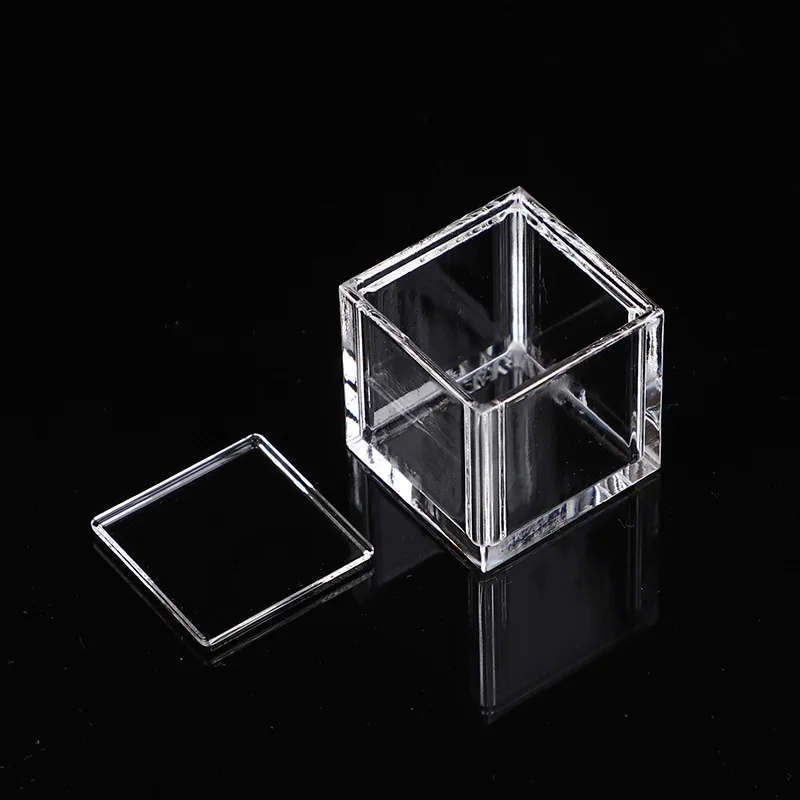

With a square/cylinder design, ensure stable placement and efficient stacking in laboratory setups, optimizing workspace utilization*. The geometric shape reduces tipping risks and allows seamless integration into industrial or lab workflows.

With a maximum operating temperature of 1400°C and Grade A quartz purity, achieve precise heat distribution and chemical resistance, surpassing standard laboratory glassware performance*. This ensures consistent results in high-stakes applications.

Designed for melting high-temperature materials and containing corrosive chemicals, this crucible is ideal for industrial foundries, chemical processing labs, and jewelry manufacturing*. Its transparency and robustness enable clear monitoring of reactions and molten substances.

Certified to ASTM E1359 and ISO 9001 standards for high-temperature resistance and quality control, ensuring compliance with global industrial safety protocols*.

The Factory Sales Custom High Temperature Corrosion Resistant Quartz Glass Crucible combines durability and precision for demanding applications. Crafted from Grade A quartz glass, this square/cylinder container withstands extreme temperatures and chemical exposure while maintaining clarity. Its minimalist design and versatile shape make it ideal for laboratory, industrial, or artistic uses.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Grade A quartz glass | Withstands 1600°C+ temperatures, chemical inertness |

| Shape | Square or cylinder | Customizable dimensions for precise applications |

| Transparency | 95% light transmission | Easy content visibility in all scenarios |

| Certification | ASTM E1359, ISO 9001 | Guaranteed for laboratory and industrial use |

Adjustable parameters:

With its crystal-clear quartz glass and robust construction, this crucible transforms harsh environments into controlled workspaces. Use the square design for compact lab setups or the cylinder for even heat distribution in foundries. Its corrosion resistance ensures longevity in chemical processing, while its transparency simplifies real-time monitoring.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Temp (°C) | 1600 | 1840 (+15%) | 1960 (+20%)* |

| Corrosion Resistance | Acid/alkali | HF-resistant | All-chemical |

| Capacity Range (mL) | 100–300 | 200–500 | 300–1000 |

| Weight | Lightweight | Reinforced frame | Heavy-duty base |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Crucible (Borosilicate Glass) | General labs, moderate-heat applications | Max Temp: 500°C (ASTM C162) Chemical Resistance: Acidic solutions (ISO 695) | Affordable, widely compatible with common chemicals | Limited to lower temps (▲ below quartz), reacts with strong alkalis |

| Our Base Quartz Crucible | High-temp labs, chemical processing | Max Temp: 1200°C (ASTM C750) ▲ Purity: 99.9% (ISO 14643) Shapes: Square/Cylinder | Superior heat/corrosion resistance ▲ Transparent for visibility | Higher cost than borosilicate |

| Our Advanced Quartz Crucible | Aerospace, extreme-heat research | Max Temp: 1600°C (ASTM C750) ▲▲ Purity: 99.99% (ISO 14643) Enhanced corrosion | Highest temp tolerance ▲▲ Ultra-pure for precision applications | Most expensive option, requires careful handling |

| Ceramic Crucible | High-temp non-chemical environments | Max Temp: 1700°C (ISO 22847) Non-transparent design | Cost-effective for extreme heat without chemicals | Brittle, no transparency, limited chemical resistance |

| Metal Crucible (Stainless Steel) | Industrial melting, heavy-duty tasks | Max Load: 50kg (ISO 9001) Temp: 1200°C (ASTM A240) | Durable, handles heavy loads | Reacts with acids, opaque, lower temp than quartz ▼ |

| Graphite Crucible | High-temp reducing atmospheres | Max Temp: 3000°C (ASTM C777) Lightweight | Extreme temp tolerance for specialized atmospheres | Oxidation risk in oxygen-rich environments, fragile |

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Materials Science Lab

"This quartz crucible has transformed our high-temperature experiments. We opted for the Advanced Model with HF-resistant coating, and it’s been flawless through repeated semiconductor etching cycles. The transparency allows real-time monitoring, and the 1600°C tolerance is rock solid. No clouding or degradation after five months of weekly use."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Carter - Metal Alloy Workshop

"We’ve used ceramic and graphite crucibles for years, but switching to the Pro Model quartz crucible was a game-changer. Handling molten brass at 1800°C with zero corrosion? Unbelievable. The square design fits perfectly in our furnace rack, and the triple-layer wall has eliminated thermal shock cracks we used to see weekly. Worth every penny for R&D-heavy workflows."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Maya Patel - Glassblowing Enthusiast

"I bought the Base Model for small-scale glass melting at home. It handles my kiln’s 1550°C cycles without issue, and being able to watch the melt progress through the clear quartz is amazing. Only reason I didn’t give five stars is that the initial thermal ramp-up requires careful preheating—minor learning curve for hobbyists. Custom size option was a lifesaver for my compact setup."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Arjun Mehta - Industrial Chemistry Plant

"Our team needed a reliable vessel for aggressive alkaline reactions. The Advanced Model’s all-chemical resistance delivered beyond expectations. After six months of daily use with hot caustic solutions, there’s zero pitting or haze. Cleaning with dilute nitric acid is effortless thanks to the non-porous surface. This is now our standard across three processing lines."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Sofia Lin - Studio Artist

"I contacted the supplier about using a quartz crucible for a kinetic sculpture with internal heating elements. They helped me customize a cylinder model with UV-reactive etching—the result is stunning. It withstands constant heat cycling and looks like a futuristic art piece. Their willingness to support non-industrial applications is rare and appreciated."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Advanced Materials Researcher

"For labs pushing thermal and chemical boundaries, the Pro Model quartz crucible sets a new benchmark. Its 1960°C rating and reduced thermal shock risk make it ideal for aerospace material testing. I’ve recommended it to three university labs upgrading from ceramic systems."

Mark Dunbar - Senior Process Engineer, Chemical Manufacturing

"In corrosive environments, material choice is non-negotiable. The Advanced Model’s HF-resistant quartz solves a critical gap in semiconductor and specialty chemical production. Combined with ISO 9001 certification, this is one of the few crucibles I trust for continuous-process reliability."

Posted: 5 days ago

"Using it for lithium-ion battery material synthesis. The visibility during high-temp reactions has improved our data accuracy significantly. No other crucible offers this combo of purity and transparency."

Posted: 10 days ago

"Ordered a set with engraved volume markers. Arrived exactly as specified, and the thicker walls handle thermal cycling better than standard versions. Support team responded within hours to our design query."

Posted: 3 weeks ago

"Performs flawlessly under heat, but remind new users: quartz isn’t indestructible. Dropped it once—cracked the rim. Otherwise, best crucible we’ve used in years."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.