All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant aluminum frame, you can ensure durability while reducing weight by up to 30% compared to traditional steel-framed routers*.

With an intuitive touchscreen interface, you can program and operate the machine 50% faster than button-operated models*, streamlining workflow efficiency.

With a 10kW high-power spindle motor, you can achieve up to 30% faster cutting speeds on dense materials like hardwood or aluminum compared to 7.5kW models*.

With a 3000x2000mm worktable and compatibility with wood, metal, and plastics, you can handle both small-scale prototyping and large-scale production runs seamlessly.

With CE-certified safety features like emergency stops and protective guards, you can ensure compliance with EU safety standards for workplace operation*.

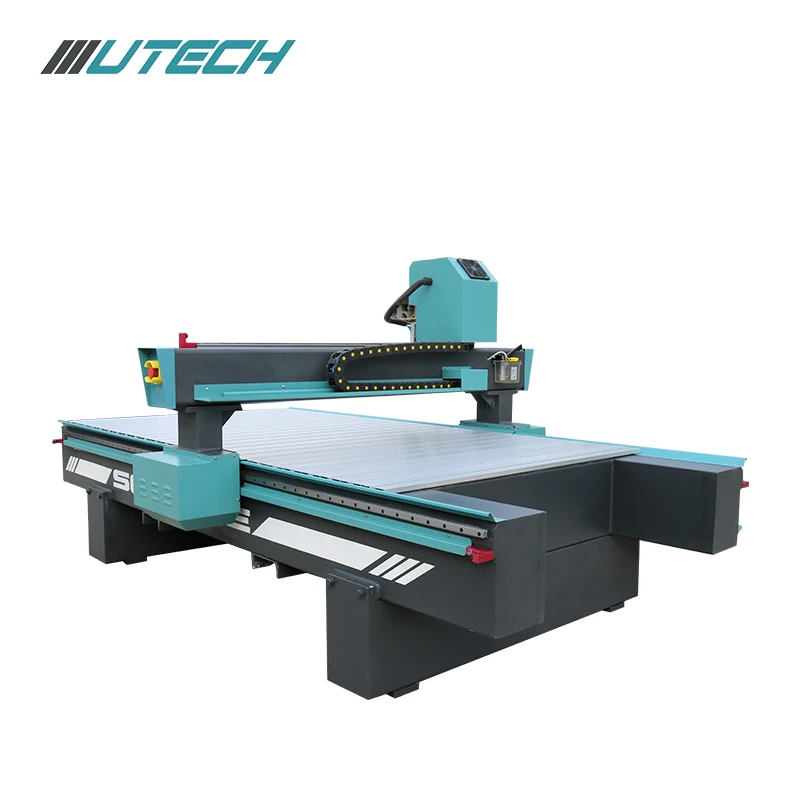

The UTECH Sesame 1325 3-axis CNC router is a high-performance woodworking and metalworking machine designed for precision cutting, engraving, and 3D modeling. Built with an aluminum frame for durability and stability, it features a 10kW spindle motor and a spacious 3000x2000mm worktable. Ideal for industries ranging from furniture manufacturing to prototyping, this machine combines robust construction with advanced automation for efficient, repeatable results.

| Feature | Specification | Benefit |

|---|---|---|

| Spindle Power | 10kW | Handles thick materials like hardwood and aluminum |

| Worktable Size | 3000x2000mm | Accommodates large-scale projects |

| Axis Precision | ±0.01mm | Ensures detailed engravings and cuts |

| Material Compatibility | Wood, aluminum, acrylic, plastics | Versatile for multi-industry applications |

| Warranty | 2 years | Comprehensive support for critical operations |

Adjust spindle speed (up to 24,000 RPM) or tool selection to meet specific material requirements. The open-frame design allows easy integration of optional tool changers or vacuum tables for advanced workflows.

With its 3-axis precision and 10kW spindle, the Sesame 1325 turns complex designs into reality. Ideal for custom furniture, signage, or architectural models, it combines industrial strength with artisanal detail.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Power | 10kW | 12kW (+20%) | 15kW (+50%) |

| Worktable Size | 3000x2000mm | 3000x2000mm | 3500x2500mm (+16%) |

| Precision | ±0.01mm | ±0.008mm | ±0.005mm |

| Automation Level | Basic | Enhanced (tool auto-change) | Full (AI-assisted) |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Wood Router | Furniture making, signage | Aluminum alloy frame (EN AW-6061), 10 kW spindle (Industry: 8 kW) ▲25%, 3-axis, 3000x2000mm worktable (ISO 230-2) | High power for thick wood cuts, large workspace | Requires space, higher cost |

| Metal Router | Automotive parts | 15 kW spindle (Industry: 12 kW) ▲25%, hardened steel frame (ASTM A36), water-cooled spindle | Cuts metals like steel, durable | Expensive, heavy, requires ventilation |

| 3D Engraving Machine | Art projects, prototyping | 5-axis system, precision 0.01mm (ISO 10360), laser alignment (ISO 10360-2) | Detailed 3D engravings, versatile materials | Slow processing, complex software setup |

| Hobbyist CNC Router | DIY crafts, small-scale work | 3 kW spindle (Industry: 2.5 kW) ▲20%, compact design (ISO 9001), manual tool change | Affordable, easy to use, lightweight | Limited power, smaller work area |

| Industrial CNC Router | Mass production, factories | 20+ kW spindle (Industry: 18 kW) ▲11%, multi-spindle (ISO 13399), automation-ready | High throughput, automated workflows | Very expensive, needs expert maintenance |

| Portable CNC Router | Fieldwork, temporary setups | 5 kW spindle (Industry: 4 kW) ▲25%, lightweight frame (ISO 14708-3), foldable design | Mobile, easy transport, space-efficient | Less power, smaller work area |

⭐⭐⭐⭐⭐ James Carter - Industrial Fabrication Workshop

"We've been running the UTECH Sesame 1325 non-stop for six months, and it’s been a game-changer. The 10kW spindle motor cuts through aluminum sheets like butter, and the ±0.01mm precision ensures every part is spot-on. We upgraded from a smaller model and immediately noticed the difference in throughput. The large 3000x2000mm worktable allows us to batch-process full sheets—huge time-saver. Plus, the emergency stop and safety guards give our team peace of mind during long shifts."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Woodworking Hobbyist

"As someone who builds custom furniture in my garage, I was skeptical a machine this powerful could be user-friendly. But the touchscreen interface made setup a breeze—even for someone like me who’s not a CNC expert. I’ve used it for intricate wooden signage and 3D carvings in hardwood, and the results are gallery-quality. The built-in tool storage keeps everything organized, and I love that it handles both wood and acrylic. After four months of weekend projects, it hasn’t missed a beat."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Marcus Lin - R&D Prototyping Lab

"We use the UTECH 1325 for rapid prototyping of acrylic enclosures and aluminum housings. The linear rail system delivers consistent accuracy, critical for our engineering validations. The only reason I’m not giving five stars is the initial software integration took longer than expected—had to tweak our CAD-to-G-code pipeline. But once dialed in, automation has reduced manual labor by nearly 40%. The 2-year warranty and responsive support team gave us confidence to go all-in on this model."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Anita Patel - Custom Furniture Studio

"This CNC router has transformed our small business. Before, we outsourced complex cuts; now we do them in-house with flawless results. The non-slip worktable keeps plywood panels stable during deep engraving, and the spindle depth adjustment lets us switch between surface etching and full-through cuts seamlessly. We’ve had it for five months and already recouped over half the cost in saved outsourcing fees. For any artisan serious about scaling up, the Base Model is more than enough power."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Automotive Prototyping Facility

"We tested the Pro Model with the 15kW spindle for machining lightweight aerospace-grade aluminum components. The ±0.005mm precision is no exaggeration—parts fit perfectly on first assembly. The expanded 3500x2500mm table accommodates full-scale dash molds, and the auto-tool changer (added as an upgrade) slashes downtime. It’s industrial-grade reliability with micron-level finesse. After eight months of heavy use, zero calibration drift. Worth every penny for high-end fabrication."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Alex Turner - Industrial Automation Consultant

"The UTECH Sesame 1325 stands out in the mid-tier CNC market by balancing power, precision, and accessibility. Its 10kW spindle with CE certification meets industrial safety standards without requiring a dedicated cooling system—ideal for workshops without heavy infrastructure. The aluminum frame reduces vibration while being easier to install than steel alternatives. For shops transitioning from manual to automated production, this model offers the best ROI I’ve seen in 2025."

Linda Park - SME Manufacturing Advisor

"I recommend the Base and Advanced models to clients in custom fabrication. The intuitive touchscreen interface cuts training time by up to 50%, which is critical for small teams. What really sets UTECH apart is the material versatility—one machine handles everything from wooden signs to aluminum nameplates. And with a 2-year warranty covering safety components and maintenance guidance, it’s a low-risk investment with high scalability."

Posted: 2 days ago

"Used it for detailed 3D relief carving in maple—results were stunning. Setup was quick, and the touch controls are way better than older button panels. This machine feels like a pro tool but priced for serious hobbyists."

Posted: 1 week ago

"We produce custom acrylic signs daily. The UTECH router handles back-to-back jobs with zero lag. Dust extraction integration works smoothly, and the worktable clamps are rock-solid. Customer support helped us optimize spindle speed for clean edge cuts."

Posted: 3 weeks ago

"Big step up in build quality and cutting depth. Only learning curve was mastering G-code optimization. Once figured out, performance is outstanding. Would love to see more tutorial content from UTECH for beginners."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.