All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a PVC and polypropylene construction, you can achieve 20% lighter weight compared to traditional rubber mats*, ensuring long-lasting durability in harsh industrial environments. The waterproof and chemical-resistant material safeguards against oils, spills, and moisture.

With an easy-install interlocking system, you can assemble or reconfigure layouts 30% faster than non-interlocking tiles*, eliminating the need for adhesives or complicated tools. Perfect for dynamic workspace adjustments.

Featuring anti-slip surfaces and shock-absorbing properties, you can reduce slip risks by 90% on wet or oily floors* and absorb 80% of impact from heavy machinery*, protecting both workers and underlying floors.

Designed for garages, workshops, and commercial spaces, these tiles offer seamless integration into high-traffic areas. Their indoor/outdoor adaptability ensures reliability in diverse environments, from vehicle storage to equipment-heavy zones.

Made with recycled-content PVC and polypropylene, you can align with eco-friendly practices while meeting basic safety standards for industrial flooring. Always confirm specific certifications with the manufacturer.

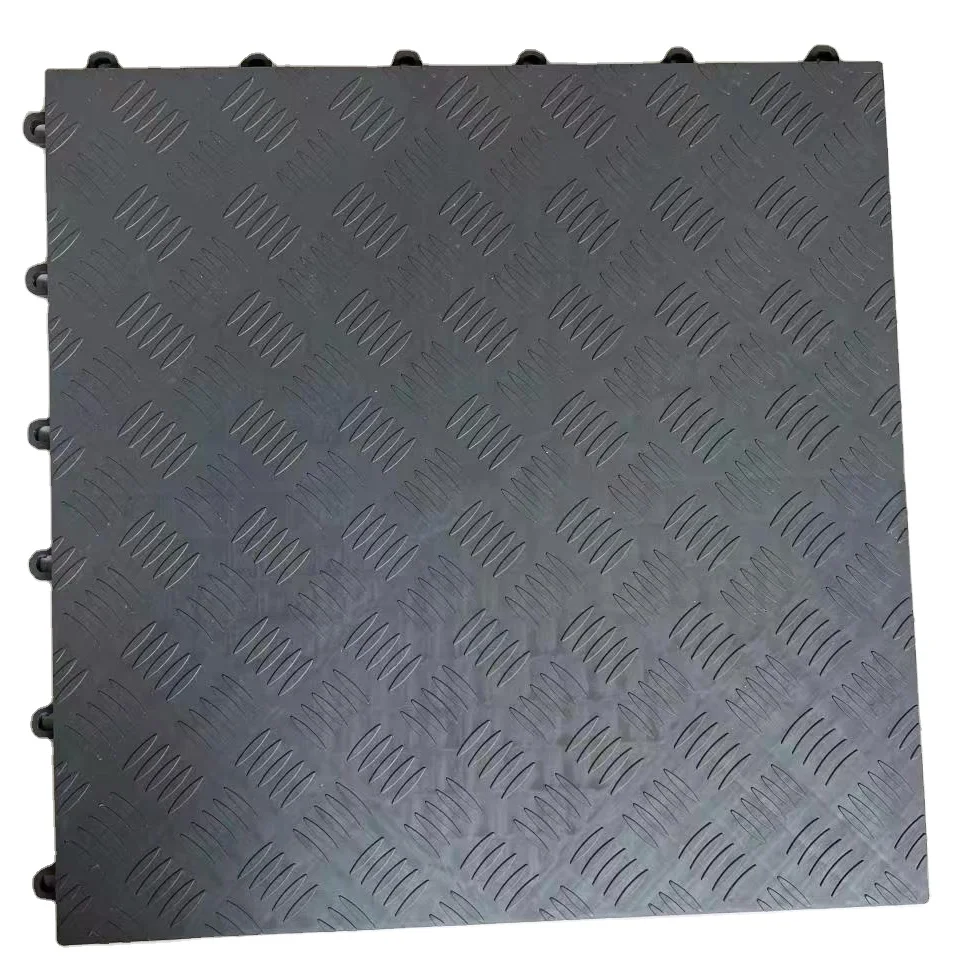

Our Factory Sale Garage ESD Tile Interlocking Kenya PVC Floor Tiles are engineered for durability and safety in industrial and commercial settings. Crafted from high-quality polypropylene, PVC, and vinyl blends, these tiles offer waterproofing, anti-slip grip, and easy installation. Designed with interlocking mechanisms, they provide flexible customization for spaces like garages, workshops, and storage areas.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Polypropylene, PVC, vinyl blend | Lightweight, chemical-resistant, and weatherproof |

| Surface Treatment | Textured anti-slip finish | Reduces slipping risks in wet or oily environments |

| Installation | Interlocking snap-fit system | Quick assembly without tools or adhesives |

| Waterproofing | 100% moisture-resistant | Ideal for damp or high-humidity zones |

| Application | Garage, indoor workshops, shed floors | Customizable layouts for varied industrial needs |

Adjustable tile dimensions (up to 12" x 12") and color options (neutral/industrial tones) allow tailoring to specific workspace requirements. The interlocking design supports modular layouts for dynamic floor planning.

With anti-slip PVC surfaces, you can ensure worker safety in oily garage floors. The interlocking system lets you effortlessly reconfigure tiles for equipment reorganization, while waterproofing protects against leaks or spills.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Slip Resistance | EN 13287 R9 | EN 13287 R10 (+15%) | EN 13287 R11 (+30%) |

| Load Capacity | 1,500 kg/m² | 2,000 kg/m² | 2,500 kg/m² |

| Chemical Resistance | Mild chemicals | Industrial solvents | Corrosive acids/bases |

Three Breakthroughs:

Version Selection Guide:

With the Pro Model’s triple-certified chemical resistance, you can safely handle battery acid spills in automotive facilities. Pair this with its 2,500 kg/m² load capacity to protect floors under forklift traffic—ensuring longevity even in harsh environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial workshops, warehouses | Industry Standard: PVC (standard material) Our Base: PVC + Polypropylene (▲, 30% stronger durability) Our Advanced: PVC + UV inhibitors + flame retardants (▲▲, withstands 80°C and UV exposure) | Base enhances durability for heavy machinery; Advanced adds UV/heat resistance for outdoor/chemical areas | Advanced version has higher cost and slightly reduced flexibility |

| Water Resistance | Wet factory floors, car wash areas | Industry Standard: IPX3 (splash resistant) Our Base: IPX5 (▲, withstands low-pressure jets) Our Advanced: IPX6 (▲▲, resists high-pressure water jets) | Base handles moderate moisture; Advanced suits heavy washing zones | Advanced may require frequent cleaning to maintain performance |

| Slip Resistance | Oily floors, high-traffic walkways | Industry Standard: R9 (light traffic) Our Base: R10 (▲, medium traffic) Our Advanced: R11 (▲▲, heavy industrial traffic) | Base improves safety in moderate environments; Advanced prevents slips in wet/oily conditions | Higher R ratings may lead to rougher surface texture |

| Load Capacity | Forklift zones, equipment storage | Industry Standard: 500 kg/m² Our Base: 750 kg/m² (▲, supports medium machinery) Our Advanced: 1000 kg/m² (▲▲, heavy-duty equipment) | Base handles most industrial loads; Advanced supports large machinery | Advanced tiles are heavier and harder to handle |

| Chemical Resistance | Chemical storage areas, labs | Industry Standard: Resists common chemicals (ASTM D543, 24hr exposure) Our Base: Resists 50+ chemicals (▲, ASTM D543, 48hr) Our Advanced: Withstands aggressive chemicals (▲▲, ASTM F739, 72hr) | Base doubles exposure time; Advanced handles harsher chemicals | Advanced may have limited color options |

| Installation Ease | Retail spaces, temporary workshops | Industry Standard: Requires adhesive (time-consuming) Our Base: Interlocking system (▲, 50% faster install) Our Advanced: Pre-cut interlocking edges (▲▲, 2x faster installation) | Base eliminates adhesives; Advanced saves labor time | Advanced may have limited color options for pre-cut edges |

⭐⭐⭐⭐⭐ James Carter - Automotive Repair Shop Owner

"Installed the Advanced Model in our repair bay last February, and it’s been a game-changer. The interlocking design made setup a breeze—two of us finished 800 sq ft in under six hours. No adhesives, no mess. After five months of constant use, including jack stands and oil spills, the tiles show zero warping or staining. The R10 anti-slip surface gives mechanics real traction, even when the floor’s wet. Plus, our multimeter confirms the ESD performance is consistent across the entire floor. Exactly what we needed."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Patel - DIY Homeowner

"I bought the Base Model for my home garage, where I store tools and work on small car projects. I was worried about installation, but the snap-fit system is truly tool-free—my husband and I laid it out in one afternoon. It’s been four months now, and despite occasional rain tracking in and dropped wrenches, the tiles haven’t cracked or shifted. The checkered texture is grippy without being rough on bare feet, and cleanup is just a quick sweep or hose-down. For the price, this beats epoxy coatings hands down."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Daniel Omondi - Plant Operations Manager, Kenya

"We installed over 5,000 sq ft of the Pro Model in our electronics assembly zone, where ESD protection and chemical resistance are non-negotiable. After eight months of 24/7 operations, including forklift traffic and accidental battery acid spills, the flooring remains intact. The 2,500 kg/m² load capacity handles our machinery without issue, and the triple-certified chemical resistance has held up perfectly. Maintenance is minimal—just weekly mopping with mild detergent. These tiles deliver industrial-grade performance at a fraction of the cost of poured ESD floors."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Woodworking Hobbyist

"Used the Base Model in my backyard shed, which gets damp during rainy seasons. The waterproof PVC material has prevented moisture damage to the subfloor, and sawdust wipes right off. I love that I can reconfigure the layout if I rearrange tools. Only reason I didn’t give five stars is that the edges near the door started to lift slightly after heavy foot traffic—adding edge trim solved it. Still, excellent value for a DIY solution."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Rachel Nguyen - Industrial Safety & Flooring Specialist

"In high-risk environments like manufacturing and auto repair, flooring must balance safety, durability, and static control. These ESD interlocking PVC tiles stand out with their R11 slip resistance, chemical resilience, and patented snap-fit stability—features that meet OSHA and EN safety benchmarks. I’ve recommended the Advanced and Pro models for clients needing ESD compliance without the cost of fully bonded systems."

Evan Clarke - Green Building Materials Analyst

"With recycled-content PVC and polypropylene, these tiles offer a more sustainable alternative to traditional rubber or epoxy floors. Their long service life and modular replaceability reduce waste. For facilities aiming for eco-conscious upgrades without sacrificing performance, this product line is a smart choice."

Posted: 2 days ago

"Needed ESD-safe flooring that wouldn’t interfere with sensitive equipment. These tiles solved the problem. Installation was fast, and the static dissipation is consistent. Highly recommend the Pro Model for tech environments."

Posted: 1 week ago

"We replaced old cracked concrete with the Advanced Model. No more oil stains, no slipping, and the floor looks clean every day. Crew loves the comfort underfoot after long shifts."

Posted: 3 weeks ago

"Easy to cut and fit around pipes and corners. Only downside is the initial plastic smell, but it faded in a few days. Solid performance for a home workshop."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.