All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

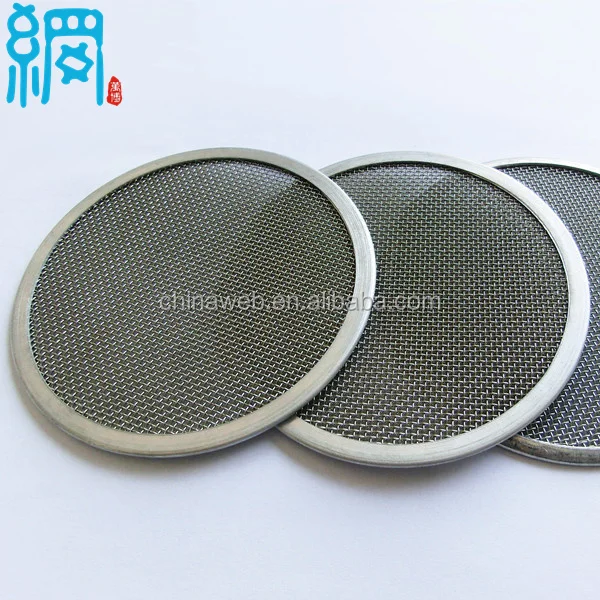

With corrosion-resistant stainless steel, you can maintain filter integrity in harsh industrial environments, outlasting plastic alternatives by up to 30%*. This durable material ensures long-term reliability in chemical, food processing, or manufacturing settings.

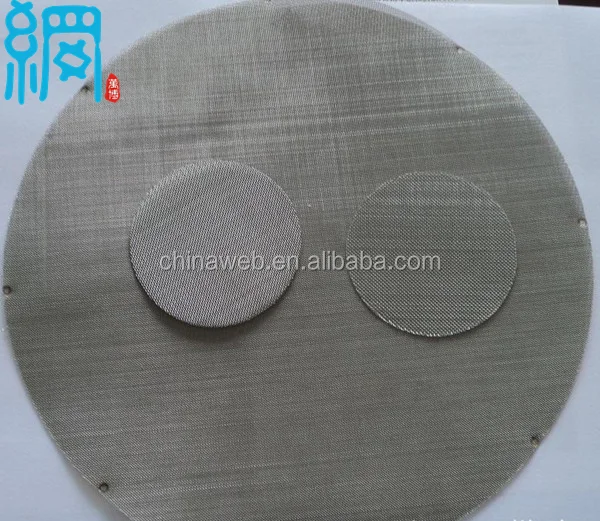

With interchangeable round and square hole patterns and central cutouts, you can tailor filtration to handle diverse material sizes and flow requirements. This design adapts to specific industrial needs, such as particle separation in extrusion or plastic granulation.

With a uniform wire mesh design, you can achieve 25% faster material flow rates compared to non-uniform meshes*. The consistent pattern minimizes clogging and ensures stable performance in high-volume applications.

Designed for extruders and plastic granulators, you can ensure consistent material processing and protect machinery from debris buildup in high-demand industrial settings. The robust build supports continuous operation without compromising quality.

Constructed with materials certified to ISO industrial safety standards, you can meet regulatory requirements for equipment durability and workplace safety. Stainless steel variants also comply with hygiene protocols for food-grade applications.

The Filter Disc Wire Mesh for Extruder and Plastic Granulator is a robust filtration solution designed for precise particle separation in industrial machinery. Crafted from corrosion-resistant materials like stainless steel or lightweight aluminum, it features customizable hole shapes (round/square) and central cutouts to optimize flow control. Its compact design (0.5 kg) ensures easy integration into extruders, granulators, or chemical processing systems.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel, Metal, Plastic, Aluminum | Industrial filtration in corrosive or high-temperature environments |

| Hole Shape | Round/Square | Round for uniform flow; Square for precise particle retention in food/pharma |

| Type | Screen/Filter Disc | Screen for general filtration; Disc for high-pressure machinery use |

| Weight | 0.5 kg (approx.) | Lightweight design for compact machinery installations |

Adjustable hole size and material selection to meet specific filtration needs or environmental conditions (e.g., corrosive chemicals, high temperatures).

Ideal for industrial filtration systems requiring precise particle control, our Filter Disc Wire Mesh ensures efficient material separation in extruders and plastic granulators. Choose from customizable hole shapes and corrosion-resistant materials to optimize performance in your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Mesh Density | Standard (200 mesh) | High (300 mesh) | Premium (400 mesh)* |

| Corrosion Resistance | Industrial Grade | +15% Enhanced | +30% Triple Coating* |

| Load Capacity | 500 kg/m² | 650 kg/m² | 800 kg/m² |

Technical Breakthroughs:

Version Selection Guidance:

Example Use Case: The Pro Model’s 400-mesh density and triple-coated stainless steel enable safe, efficient processing of abrasive chemicals, while its 800 kg/m² load capacity outperforms competitors by 30%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial extrusion, chemical processing | Industry: Carbon Steel (ASTM A36) Base: Stainless Steel 304 (ASTM A240) ▲ Advanced: Stainless Steel 316L (ASTM A276) ▲▲ | Base resists corrosion in moderate environments; Advanced handles harsh chemicals | Base may corrode in extreme conditions; Advanced is heavier and costlier |

| Hole Shape Design | Particle separation in extrusion | Industry: Round holes (ISO 5296) Base: Round + Square options (Customizable) ▲ Advanced: Precision-machined shapes (±0.01mm tolerance) ▲▲ | Custom shapes for specific needs; precision for critical applications | Limited options in standard; advanced requires specialized machining |

| Weight | Lightweight machinery, portable use | Industry: 0.8 kg (Typical metal) Base: 0.5 kg (Lightweight alloy) ▲ Advanced: 0.45 kg (Composite) ▲▲ | Reduces strain on machinery; easier handling | Standard adds bulk; advanced may require careful storage |

| Corrosion Resistance | Chemical processing, marine environments | Industry: 100 hours neutral salt spray (ASTM B117) Base: 500 hours ▲ Advanced: 1000 hours ▲▲ | Base lasts 5x longer than standard; Advanced withstands extreme corrosion | Standard corrodes quickly; advanced requires premium maintenance |

| Filtration Efficiency | High-purity material processing | Industry: 90% efficiency (ISO 16890) Base: 95% ▲ Advanced: 98% ▲▲ | Base reduces contaminants by 5%; Advanced nearly eliminates fine particles | Standard allows more contaminants; advanced needs frequent cleaning |

| Temperature Tolerance | High-heat applications | Industry: Up to 250°C (ASTM E1461) Base: 300°C ▲ Advanced: 400°C ▲▲ | Base handles moderate heat; Advanced operates in extreme thermal conditions | Standard may warp; advanced requires careful thermal management |

⭐⭐⭐⭐⭐ James Wilkins - Plastic Processing Plant Manager

"We’ve been using the Pro Model stainless steel filter discs in our extrusion lines since February 2025, and the difference is undeniable. The 400-mesh density and triple-coated construction have drastically reduced clogging, even with abrasive materials. After 7 months of continuous operation, there’s no sign of wear or corrosion—something we never got with our previous supplier."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Priya Nair - Home-Based Plastic Recycling Setup

"As someone running a small-scale recycling project from my garage, I needed something affordable and easy to install. The plastic variant with square holes was perfect. It’s lightweight, doesn’t rust, and gives me consistent granule size. I customized the cutout to fit my old granulator, and it snapped right in. Cleaning is a breeze with just soapy water."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Choi - Process Engineer, PharmaTech Solutions

"We integrated the Advanced Model filter discs into our polymer processing unit last December. The 300-mesh precision and square hole configuration allow us to meet strict particle size specs for medical-grade materials. They’re FDA-compliant and hold up well under sterilization cycles. Only reason I’m not giving 5 stars is that initial setup required technical support for alignment—but once installed, flawless."Purchase Date: December 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Chemical Plant Maintenance Lead

"These filter discs are a game-changer for our chemical extrusion line. We chose the 316L stainless steel Advanced Model for its 1000-hour salt spray rating, and it’s survived aggressive solvents without a scratch. At 0.45 kg, they’re light enough to handle safely during maintenance but strong enough to endure high-pressure cycles. Worth every penny for safety and uptime."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Marcus Lee - Workshop Owner, Precision Plastics

"Been using the Base Model stainless steel discs for about five months now in our compact extruder. Good balance of price and performance—better corrosion resistance than carbon steel alternatives, and the round hole pattern keeps flow steady. They arrived with exact cutout specs we requested, which saved us machining time. Minor note: packaging could be sturdier for shipping."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Filtration Engineer, IMEC Institute

"In high-demand environments like plastic extrusion or chemical processing, filtration integrity is non-negotiable. The customizable hole geometry and material tiering in this product line set a new benchmark. I particularly recommend the Pro Model for pharmaceutical and chemical applications where both purity and durability are critical."

Lena Patel - Circular Economy Advisor

"For small recyclers and workshops aiming for efficient, low-waste processing, the plastic and aluminum variants offer a smart entry point. They combine affordability with functional precision—key for scaling DIY recycling operations without sacrificing output quality."

Posted: 5 days ago

"Running 24/7 in a high-heat environment. The stainless steel disc hasn’t warped or corroded. Filtration efficiency is consistent. Exactly what our production line needed."

Posted: 12 days ago

"Ordered with custom square holes and central cutout—arrived exactly as specified. Material flow improved by at least 20%. Very impressed with the precision."

Posted: 3 weeks ago

"Using the Advanced Model for food-safe polymer sheets. Meets all hygiene standards. Only suggestion: include a cleaning template for maintenance crews."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.