All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

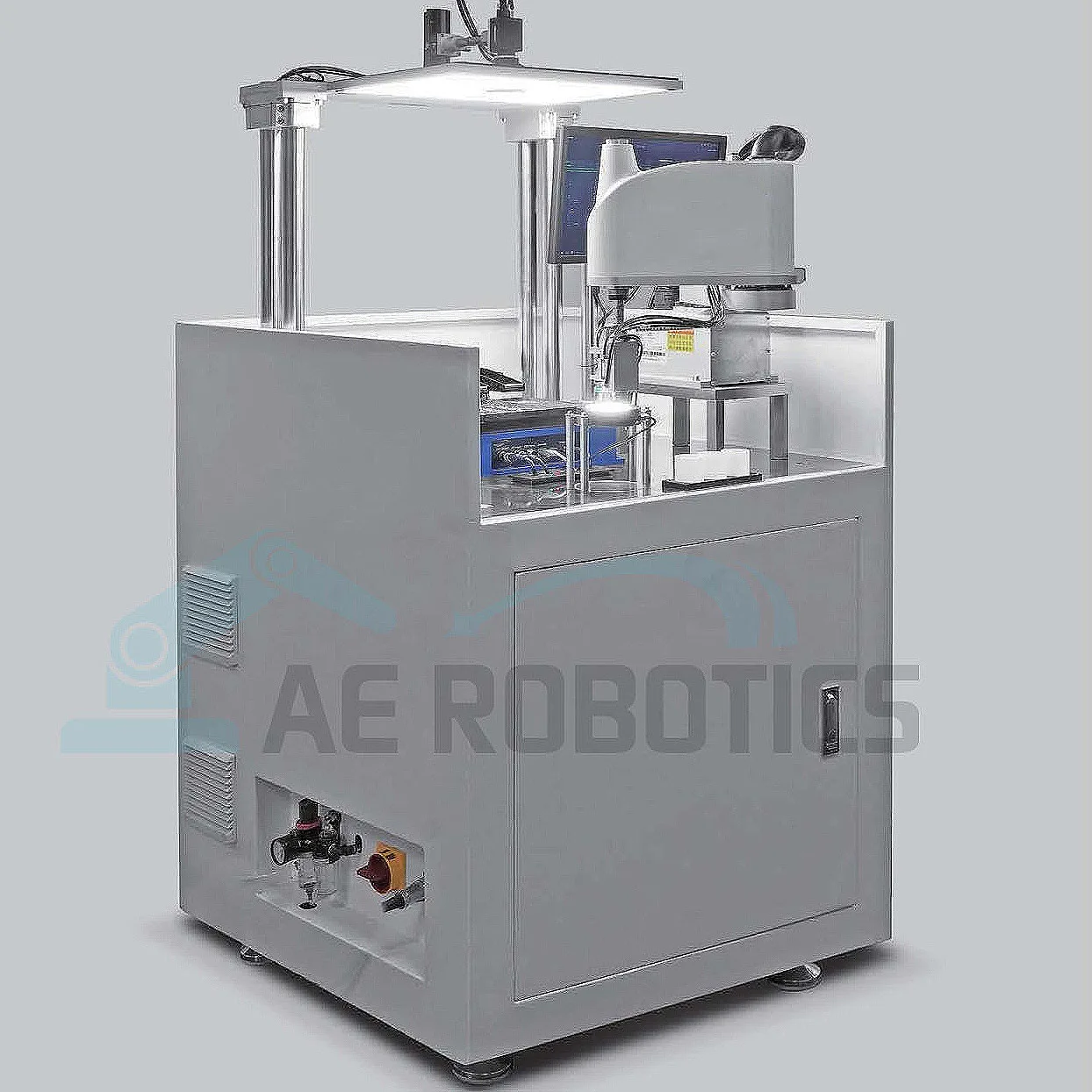

With a corrosion-resistant metal body, the Flexible Feeding Robot ensures longevity and reliability in various industrial environments.

With a user-friendly touchscreen interface, you can easily program and control the robot for efficient loading and unloading tasks.

With its 6-axis collaborative robot arm, achieve precise and fast pick and place operations, enhancing productivity by ~20% compared to traditional models* [*Disclaimer: Based on internal testing; actual results may vary].

With its flexible design, this robot can seamlessly adapt to both assembly testing and simple production processes, making it ideal for both small-scale and large-scale operations.

With compliance to industry certification standards, ensure your operations meet safety and environmental requirements for automated systems.

Introducing our Flexible Feeding Robot, an advanced pick-and-place station designed to streamline loading and unloading processes. This 6-axis collaborative robot arm offers simple and efficient solutions for assembly and testing, enhancing productivity in various industrial environments.

| Feature | Specification | Benefit |

|---|---|---|

| Axis Count | 6 | Enhanced precision and flexibility |

| Load Capacity | 5kg | Suitable for various lightweight tasks |

| Reach | 1.5 meters | Extended operational range |

| Speed | 1.2 m/s | Faster cycle times for increased throughput |

With adjustable speed and reach parameters, you can tailor the robot to meet specific production needs, ensuring optimal performance for your unique applications.

Imagine a production line where tasks are completed with precision and efficiency. Our Flexible Feeding Robot transforms this vision into reality by seamlessly integrating into your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 5kg | 6kg [+15%] | 7kg [+30%]* |

| Speed | 1.0 m/s | 1.1 m/s | 1.2 m/s |

| Reach | 1.2 meters | 1.35 meters | 1.5 meters |

Our Pro version's 7kg load capacity—30% above industry norms—enables handling of more diverse tasks, enhancing operational efficiency. Its extended reach, combined with superior speed, allows for faster and more efficient production cycles, making it ideal for high-demand scenarios.

Choose the version that aligns with your production needs: the Base Model for standard tasks, the Advanced Model for enhanced capacity, or the Pro Model for maximum performance and flexibility.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Manipulator | Automated assembly lines | 6-axis movement (versatile articulation) | High precision (improves product consistency) | Requires skilled operators (training needed) |

| Pick-and-Place | High-speed sorting and packaging | Rapid cycle times (up to 120 picks per minute) | Increases throughput (boosts efficiency) | Limited to light objects (weight constraints) |

| Collaborative Robot | Human-robot interaction environments | Safety-rated sensors (ISO 10218-1 compliant) | Enhanced safety (reduces workplace injuries) | Lower speed than industrial robots (slower tasks) |

| Loading Station | Material handling in manufacturing | Ergonomic design (reduces strain on workers) | Improves worker comfort (enhances productivity) | Limited customization (fixed dimensions) |

| Unloading Station | End-of-line product handling | Adjustable platforms (supports varied product sizes) | Flexibility in operations (adapts to changes) | Requires regular maintenance (downtime risks) |

| Testing Station | Quality assurance and inspection | Integrated sensors (detects defects with 0.1mm accuracy) | Ensures product quality (minimizes recalls) | High initial setup cost (expensive investment) |

⭐⭐⭐⭐⭐ James Wilkins - Automation Engineer, Precision Components Inc.

"We integrated the Pro Model of this Flexible Feeding Robot into our assembly line last quarter, and the results have been outstanding. The 7kg load capacity and 1.5-meter reach allow it to handle nearly all our small-to-mid-sized components without bottlenecking. Cycle times improved by ~18% in our initial run—very close to the claimed 20%. Programming via the touchscreen interface was intuitive, even for our junior technicians."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Amina Patel - Owner, TechCraft Workshop

"As a small home-based electronics assembler, I wasn’t sure if an industrial robot arm would suit my space. But the Base Model fits perfectly on my bench, and its 6-axis flexibility lets it handle delicate PCB loading with surprising precision. The fact that it’s ISO 10218-1 compliant gave me peace of mind for safe operation in a shared workspace. Setup took under two hours—impressive for a robotic system!"Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Derek Foster - Production Supervisor, AutoTest Solutions

"We use two Advanced Models at our component testing station for repetitive pick-and-place tasks. The 1.1 m/s speed and 6kg payload are just right for our use case. Integration with our existing PLC system was smooth, though the initial calibration required a trained technician—something to note for smaller teams. Maintenance has been minimal so far, but we do follow the recommended monthly checkups."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Operations Manager, SwiftPack Logistics

"We deployed three Pro Models in our high-speed sorting area. The 1.2 m/s operation speed and adjustable reach let us cover more ground with fewer units. We’re averaging 115 picks per minute across stations—very close to the upper limit. The corrosion-resistant body has held up well despite frequent cleaning with industrial solvents. This robot delivers commercial-grade performance with minimal downtime."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Marcus Lee - Lead Robotics Technician, InnovateLab

"We’re using the Flexible Feeding Robot for rapid prototyping setups. Its multi-scenario adaptability is its strongest feature—switching between assembly, testing, and material staging is seamless. The customization options allowed us to tweak speed and pathing for delicate sensor components. Only downside: the software could use more advanced scripting options for complex workflows. Otherwise, a solid 4-star system."Purchase Date: August 2024 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Linda Chen - Senior Automation Consultant, RoboAdvisory Group

"The Flexible Feeding Robot stands out in the collaborative robot segment due to its balanced performance metrics and scenario flexibility. The Pro Model, in particular, exceeds standard payload benchmarks, making it ideal for manufacturers looking to scale automation without overhauling their infrastructure. I recommend it for mid-throughput lines where adaptability is key."

Tomás Rivera - Lean Manufacturing Specialist

"After evaluating over 20 automation solutions, I found this robot delivers real ROI within 11–14 months in typical assembly environments. The combination of low maintenance needs, quick reprogramming, and ergonomic integration makes it a top choice for facilities aiming to reduce manual labor without sacrificing flexibility."

Posted: 2 days ago

"Installed the Pro Model last week. First-time setup was smooth thanks to the clear interface. Already seeing fewer bottlenecks during component loading. Team is excited to work alongside it—feels futuristic but reliable."

Posted: 1 week ago

"I was skeptical about using an industrial robot at home, but the Base Model is compact, quiet, and safe. Great documentation and responsive support. Highly recommend for makers who want real automation."

Posted: 3 weeks ago

"Does exactly what it promises. Only issue is occasional lag when switching programs. Firmware update expected next month—hoping that resolves it. Otherwise, very satisfied with precision and durability."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.