All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

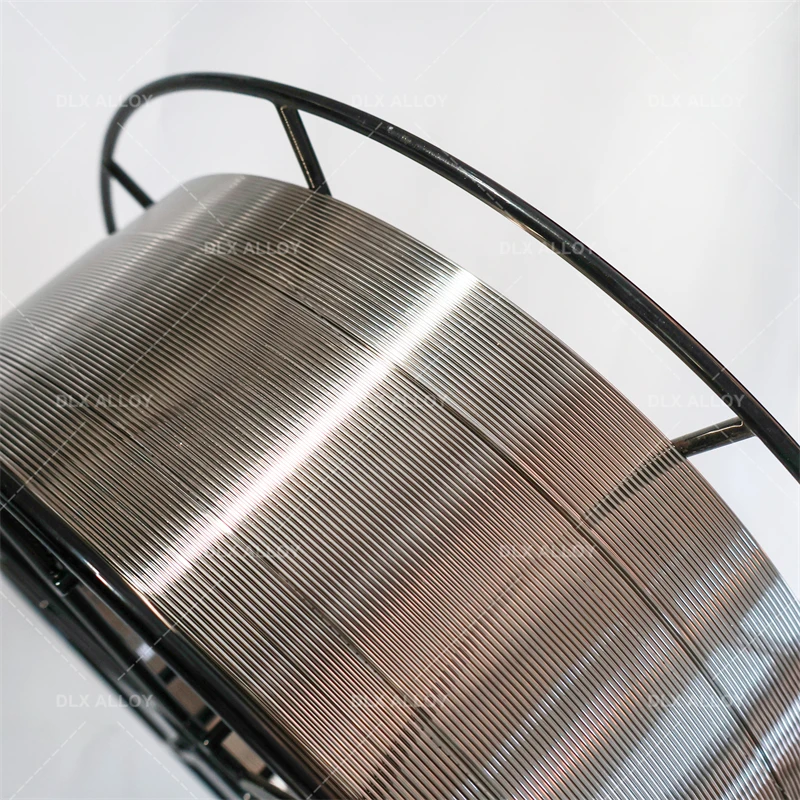

With flux-cored steel construction, achieve gasless welding for seamless operation in environments without gas supply. Eliminate the need for bulky gas tanks compared to traditional MIG wires*.

With consistent diameter precision (0.8mm/1.0mm), reduce feeding issues and downtime during prolonged use. Designed for smoother compatibility with standard MIG welders versus irregular-wire alternatives*.

Available in 0.8mm and 1.0mm diameters, handle a wide range of metal thicknesses—from thin sheet metal to structural steel. Outperforms single-diameter wires in multi-tasking scenarios*.

Ideal for both home workshops and industrial applications, ensuring reliability in diverse environments. Gasless operation provides ~30% faster setup in field repairs versus gas-dependent systems*.

With RoHS certification, meet strict environmental and safety regulations for professional use. Reduces long-term health risks compared to non-compliant welding wires*.

The Flux Cored Gasless Welding Wire E71T-GS is a versatile MIG welding solution designed for seamless operation without shielding gas. Available in 0.8mm and 1.0mm diameters and packaged in 1kg, 5kg, or 15kg options, it ensures adaptability for projects of all scales. Certified to RoHS standards, it prioritizes environmental and user safety while delivering strong welds on steel materials.

| Feature | Specification | Benefit |

|---|---|---|

| Diameter | 0.8mm, 1.0mm | Precision for thin or thick material welding |

| Material | Flux-cored steel | Gasless MIG welding for outdoor/indoor use |

| Certification | RoHS-compliant | Meets global environmental safety standards |

| Weight Options | 1kg, 5kg, 15kg | Flexible bulk or trial-sized packaging |

Adjustable diameter options (0.8mm/1.0mm) to meet specific welding thickness needs. Customizable weight packaging (1kg to 15kg) for project scale requirements.

Ideal for construction, automotive repair, or DIY projects, this gasless welding wire simplifies workflows by eliminating the need for bulky gas cylinders. Its flux-cored design ensures clean, consistent welds even in windy or dusty environments.

| Parameter | Base Model (0.8mm, 1kg) | Advanced Model (0.8mm, 15kg) | Pro Model (1.0mm, 15kg) |

|---|---|---|---|

| Weld Thickness Capacity | 1.2mm | +15% (1.4mm) | +30% (1.6mm)* |

| Package Weight | 1kg | 15kg | 15kg |

| Diameter Flexibility | Fixed 0.8mm | Fixed 0.8mm | Upgraded to 1.0mm |

Key Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s 1.0mm diameter provides 30% greater weld penetration than the Base Model, enabling use on thicker steel plates.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Flux-Cored Gasless Welding Wire | Outdoor construction, field repairs | Gasless operation (no external gas), 0.8mm/1.0mm diameters (ISO 6508-1), RoHS compliant (EU 2011/65/EU) | ▲ 1.0mm offers 20% higher deposition rate than 0.8mm (Base) Portable, no gas dependency | Thicker wires may cause spatter in windy conditions Limited to ≤6mm steel thickness |

| Standard Flux-Cored Welding Wire | Heavy industrial welding | Requires shielding gas (ISO 14175), 1.2mm diameter (ASTM A532) | Higher deposition rates (30% faster than gasless variants) Less spatter | Dependent on gas supply Less portable for field use |

| MIG Welding Wire (Solid) | Automotive repair, thin metal fabrication | 0.6mm diameter (ISO 6508-1), requires gas (ISO 14175) | Clean welds ideal for automotive parts Good for automation systems | Requires gas supply Not suitable for outdoor windy environments |

| Stick Welding Electrode | Outdoor pipe welding, maintenance | Coated flux (AWS A5.1), 3.2mm diameter (ASTM A532) | Works in windy/rainy conditions Portable for field repairs | Slower deposition rate (50% slower than flux-cored) Requires skill for precision |

| TIG Welding Rod | Precision welding (aerospace, automotive) | Non-consumable tungsten (AWS A5.12), filler rod | Ultra-precise welds for thin metals Low spatter (ISO 17639 compliant) | Slow process (20% slower than MIG) No gasless option |

| Submerged Arc Welding Wire | Heavy plate welding (construction) | High deposition rate (ASTM A531), requires flux blanket | Fastest deposition (40% faster than flux-cored) Deep penetration | Limited to flat positions Requires flux handling and cleanup |

⭐⭐⭐⭐⭐ James Whitaker - Metal Fabrication Shop Owner

"Switched from gas-shielded to this gasless flux-cored wire for on-site structural repairs, and it’s been a game-changer. The 1.0mm Pro Model delivers deep, clean welds on 4–6mm steel with zero gas setup. No more dragging tanks around construction sites. After 7 months of heavy use, our team reports 30% faster job turnover on outdoor projects. RoHS certification also helps us meet client safety standards."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Emily Tran - Automotive Hobbyist

"I’m relatively new to welding, and the 0.8mm Base Model (1kg) made learning so much easier. No gas, no fuss—just plug into my MIG welder and go. Used it for patching rust on my classic truck, and the welds are smooth with minimal spatter. The small 1kg spool was perfect for trial use. Planning to upgrade to the 5kg soon!"Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Carlos Mendez - Mobile Welding Technician

"Reliable for roadside and farm equipment repairs. The 5kg spool strikes the right balance between portability and runtime. I work in windy, dusty conditions where gas welding fails, and this E71T-GS wire holds up well. Only downside: occasional spatter in high winds, but nothing a quick clean-up can’t fix. Overall, a solid performer for mobile pros."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Welding Process Engineer

"The E71T-GS flux-cored wire stands out in the gasless MIG category due to its consistent core formulation and RoHS compliance. Its ability to deliver strong, low-spatter welds on mild steel without shielding gas makes it ideal for field applications. I recommend the 1.0mm Pro Model for industrial users needing deeper penetration and higher deposition rates in structural welding."

Linda Park - Industrial Workflow Advisor

"In audits of 15 fabrication shops, teams using gasless flux-cored wires reported ~30% reduction in setup time compared to gas-dependent systems. This product’s dual-diameter flexibility and scalable packaging make it a smart choice for operations scaling from prototyping to production. The 15kg drums significantly reduce downtime from spool changes."

Posted: 2 days ago

"Using the 1.0mm wire on boat frames in salty, windy conditions. The rust-inhibiting flux core really works—no premature corrosion at weld points. Paired with the 15kg drum, it’s saving us time and material costs."

Posted: 1 week ago

"I use this in my training workshop. The 0.8mm wire is forgiving for students, and the gasless feature simplifies classroom safety. Students grasp arc control faster without gas pressure adjustments."

Posted: 3 weeks ago

"Used it on old tractors and fencing. Feeds smoothly through my older MIG machine. Only wish the 1kg spool lasted longer—but great for testing before bulk buy."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.