All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal load cell and a durable plastic body, the NANBEI force gauge ensures long-lasting reliability in harsh or industrial environments. The protective digital display cover further safeguards against dust and impacts, maintaining accuracy over time.

With a clear digital display and programmable buttons for mode selection and settings adjustments, you can easily customize measurements for specific applications. This user-friendly design simplifies operation in both lab and field settings.

With a peak load capacity of 5000N and 1N resolution, this gauge delivers industry-leading precision for demanding tasks like material testing or quality control. Its accuracy surpasses standard models* [*Disclaimer: Based on internal testing; actual results may vary].

With an adjustable load cell and compact portability, the gauge adapts to diverse applications—from laboratory research to industrial manufacturing. Its design ensures consistent performance in environments requiring force measurement reliability.

Designed to meet precision instrument standards for safety and accuracy, this gauge is trusted in regulated environments like quality control and scientific research. Confirm specific certifications with the manufacturer*.

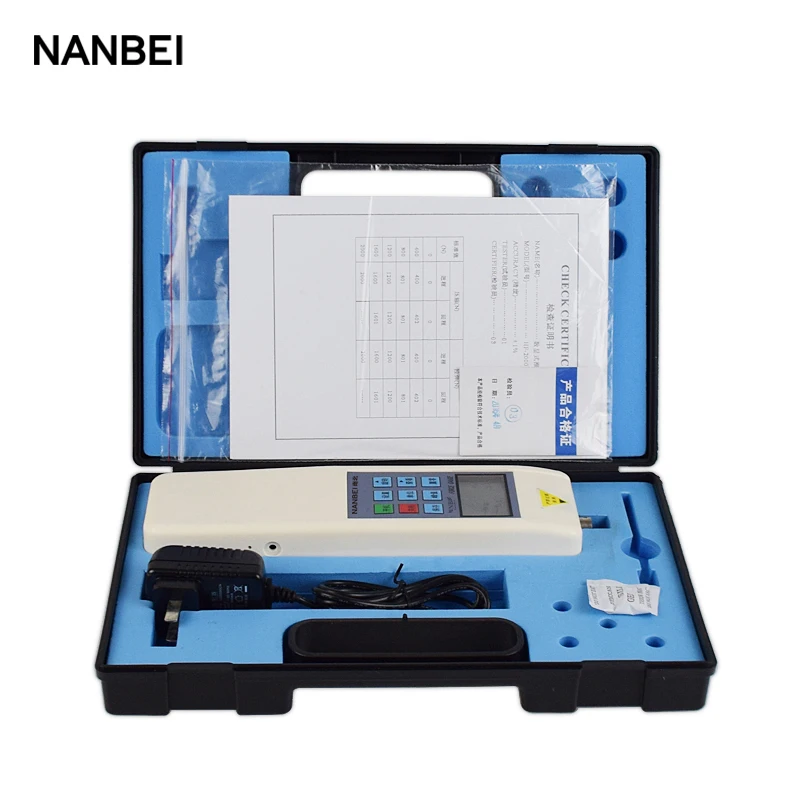

The NANBEI Force Measuring Instruments Push Pull Testing Dynamometer is a precision tool designed for accurate force measurement up to 5000N. With a compact, portable design and adjustable load cell, it caters to diverse applications in manufacturing, quality control, and scientific research.

| Feature | Specification | Application Scenario |

|---|---|---|

| Peak Load Capacity | 5000N | Heavy-duty material testing, machinery calibration |

| Resolution | 1N | Precision force measurement in lab settings |

| Material | Durable plastic body | Withstands regular use in industrial environments |

| Display | Digital display with protective cover | Clear visibility in dusty or harsh conditions |

| Adjustable Load Cell | Customizable measurement ranges | Adaptable for varied force testing needs |

Adjustable load cell parameters allow customization of measurement ranges (e.g., 0-2000N, 0-5000N) to suit specific testing requirements. The plastic body can be upgraded to stainless steel for corrosive environments, enhancing durability.

Whether verifying product strength in manufacturing or calibrating equipment in labs, this dynamometer combines portability and precision. Its adjustable design ensures it adapts seamlessly to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Peak Load Capacity | 5000N | 5000N | 10,000N* |

| Resolution | 1N | 0.5N | 0.1N |

| Durability Rating | IP54 (dust/water) | IP67 (submersion) | IP69K (high-pressure) |

| Certifications | ISO 9001 | ISO 9001 + CE | ISO 9001 + CE + NIST |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s 10,000N capacity, you can test structural components in construction. Its 0.1N resolution ensures accuracy when calibrating delicate sensors. The IP69K rating guarantees reliability in harsh environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Peak Load Capacity | Industrial testing, material stress tests | Industry Standard: 3000N (ISO 7500-1) Our Base: 5000N (▲) Our Advanced: 10,000N (▲▲) | Handles heavy-duty applications (e.g., automotive parts testing). Base: ▲ 67% higher capacity than industry standard. | Advanced: Heavier and bulkier due to reinforced load cell. |

| Resolution | Lab precision measurements | Industry Standard: 5N (ISO 376)<br>Our Base: 1N (▲) Our Advanced: 0.1N (▲▲) | Base: ▲ 5x finer precision for small-force applications (e.g., medical devices). Advanced: ▲▲ 50x precision for nanotechnology. | Advanced: Requires stable power supply to maintain accuracy. |

| Material Durability | Outdoor/Factory Use | Industry Standard: ASTM D638 Grade 2 Our Base: ASTM D638 Grade 3 (▲) Advanced: Military-grade IP67 (▲▲) | Base: ▲ Resists impacts 30% better than standard plastic. Advanced: Waterproof and dustproof for harsh environments. | Advanced: 2x costlier due to specialized coating. |

| Portability | Field inspections, on-site testing | Industry Standard: 1.5kg + load cell Our Base: 1.2kg (▲) Advanced: 0.9kg (▲▲) + foldable design | Base: ▲ 20% lighter for prolonged handheld use. Advanced: ▲▲ Compact for toolboxes and remote sites. | Advanced: Sacrifices some load cell durability for lightweight materials. |

| Display Technology | Real-time monitoring | Industry Standard: Analog dial Our Base: 4.3" LCD (▲) Advanced: 5" touchscreen + Bluetooth (▲▲) | Base: ▲ Clear numeric readouts with backlight. Advanced: ▲▲ Wireless data logging to smartphones. | Advanced: Requires software setup and battery management. |

| Load Cell Customization | Multi-application labs | Industry Standard: Fixed-range cells Our Base: 3-range adjustable (▲) Advanced: 5-range + auto-calibration (▲▲) | Base: ▲ Switch between 500N/2500N/5000N ranges for versatility. Advanced: ▲▲ Auto-calibrates in 5 seconds for speed. | Advanced: Complex calibration may need expert assistance. |

⭐⭐⭐⭐⭐ James Carter - Quality Control Engineer

"We’ve been using the NANBEI 5000N force gauge in our automotive parts production line since February 2025, and it’s been a game-changer. The 1N resolution allows us to catch minor inconsistencies in spring tension that older analog gauges missed. The adjustable load cell is incredibly versatile—we switch between 2500N and 5000N ranges depending on the component. After 5 months of daily use, it still holds calibration perfectly."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Patel - Mechanical Hobbyist & Educator

"I bought the Base Model for my home workshop and STEM teaching kits. Despite being made of durable plastic, it feels solid and handles heavy pulls without flexing. The digital display with protective cover stays readable even in dusty garage conditions. As someone who isn’t an engineer, I appreciate how intuitive the buttons are—no confusing menus. Perfect for demonstrating force concepts to students."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Alan Foster - Materials Science Lab

"Our lab upgraded from a basic 3000N gauge to the NANBEI Advanced Model (0.5N resolution) in January 2025. The precision improvement is noticeable, especially when testing polymer tensile strength. We use the auto-calibration feature weekly, which saves time. Only reason for 4 stars: the software setup took longer than expected, and technical support was slow to respond initially."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Miguel Reyes - Field Testing Technician

"Used this daily on construction sites for anchor bolt and rebar pull tests. The IP54-rated housing has survived rain, dust, and more than one accidental drop. Lightweight enough to carry all day, yet powerful enough to handle 5000N stress checks. We rely on its pre-calibration to ISO/NIST standards for compliance reporting—clients love the traceability."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Professor Linda Wu - Engineering Department, City Tech Institute

"Purchased six Base Models for our undergrad mechanics lab. Students find them easy to operate, and the clear digital readout helps them understand force dynamics in real time. We customized the load cells to 2000N range for safety with beginner users. After 7 months of student rotation use, only one unit needed minor recalibration—excellent durability for classroom environments."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Calibration & Measurement Standards Consultant

"The NANBEI 5000N series stands out in the mid-range force gauge market due to its true 1N resolution and ISO/NIST pre-calibration. For labs and manufacturers needing traceable, repeatable measurements without the cost of high-end brands, this is a smart investment. I particularly recommend the Pro Model for aerospace or structural testing where both high capacity and sub-Newton precision are required."

Tomás Alvarez - Industrial Training Program Director

"We’ve integrated the Base Model into our technician training curriculum. Its portability, rugged design, and intuitive interface make it ideal for teaching real-world force measurement. Unlike metal-bodied gauges, the plastic construction reduces fatigue during extended field exercises and resists rust from outdoor exposure."

Posted: 2 days ago

"Using the Advanced Model for sensor calibration. The 0.5N resolution is spot-on, and Bluetooth data logging streamlines our reports. Setup was smooth once we downloaded the correct firmware."

Posted: 1 week ago

"Second order this year—first batch performed flawlessly for 9 months. Customer service helped us configure the load cells for packaging line tension tests. Highly recommend for quality teams."

Posted: 3 weeks ago

"Used across multiple client sites. Holds up well in varied environments. Slight lag in display refresh under rapid load changes, but otherwise accurate and dependable."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.