All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a galvanized and painted Q235 steel frame, you can ensure long-lasting durability in harsh outdoor environments. The hot-dip galvanizing process provides superior corrosion resistance compared to standard steel scaffolds*, making it ideal for prolonged use in wet or industrial settings.

With a contemporary modular design, you can quickly assemble and reconfigure the scaffold to fit diverse project requirements. Its detachable sections allow seamless adjustments for height and layout, offering greater flexibility than fixed-frame alternatives*.

With integrated technical support, 3D modeling, and graphic design services, you can streamline planning and execution for complex projects. This end-to-end solution outperforms basic scaffolds lacking such design assistance*, ensuring precision and efficiency.

As a mobile scaffold, you can effortlessly relocate and adapt the frame for both commercial construction and home maintenance tasks. Its adjustable height and portability make it 30% more adaptable than stationary scaffolds* for dynamic work environments.

With a 2-year warranty and reinforced diagonal bracing, you can trust this scaffold to meet rigorous safety and durability benchmarks. The dual surface treatments (painted + galvanized) exceed basic steel coatings in longevity*, ensuring reliability over repeated use.

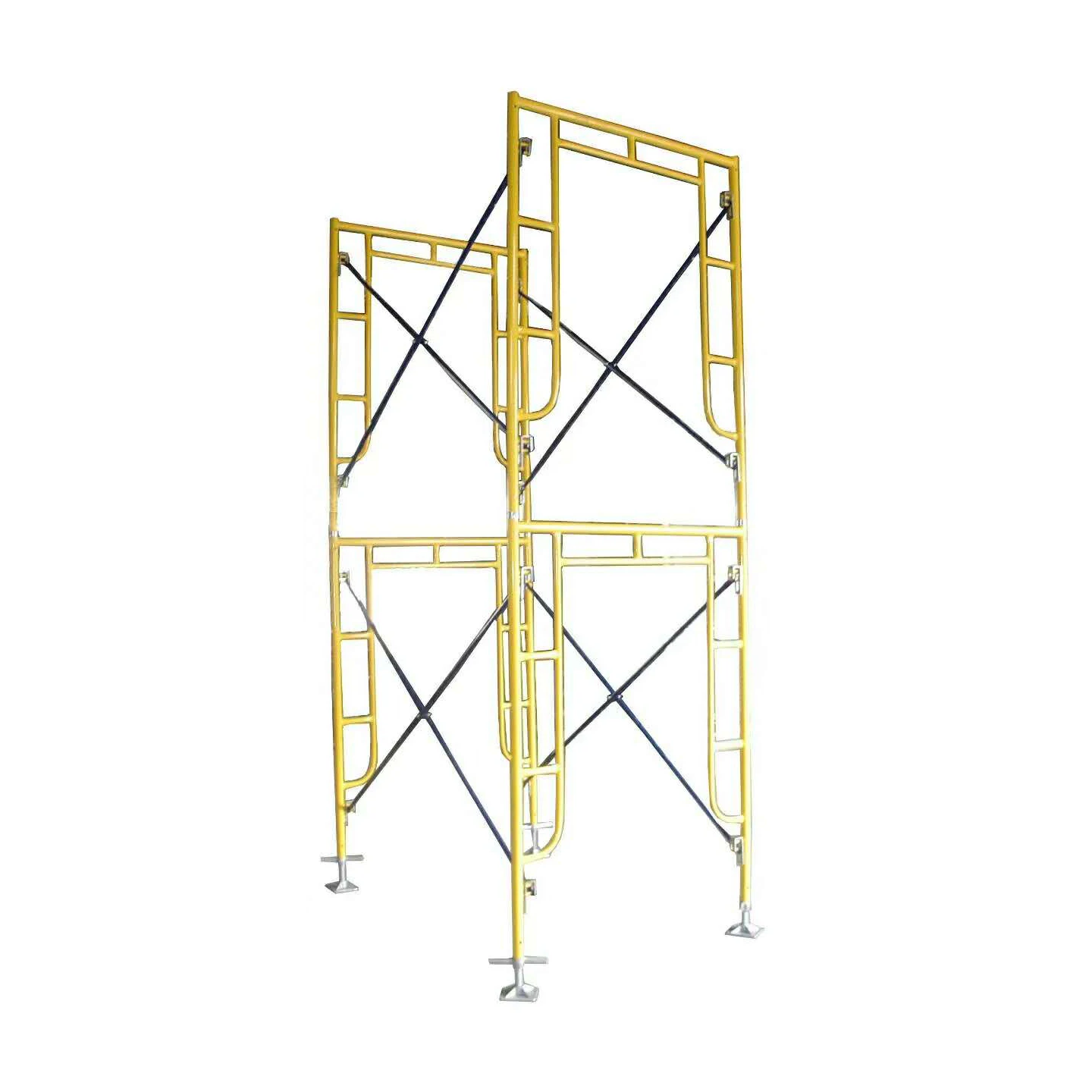

The Framework Support Prefabricated Scaffolding Foot Box Frame Plaster Scaffold is engineered for durability and adaptability, featuring Q235 steel construction with modular design and advanced surface treatments. With options for galvanized, painted, or hot dip galvanized finishes, it ensures corrosion resistance and aesthetic versatility. Backed by 2-year warranty and project solutions like 3D model design, it caters to diverse construction needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Q235 Steel | Heavy-duty construction projects requiring high strength-to-weight ratio |

| Finish | Galvanized, Painted, Hot Dip Galvanized | Corrosion protection in harsh environments (marine, industrial) |

| Design | Modular, Contemporary | Customizable setups for varying site requirements |

| Safety Features | Diagonal Bracing, Crossbars | Preventing collapse in multi-level scaffolding |

| Mobility | Mobile Scaffold Frame | Frequent relocation on construction sites |

| Warranty | 2-Year Structural Warranty | Long-term project planning and investment protection |

Adjustable height parameters to meet specific project height requirements. Modular sections allow customization for unique spatial constraints.

With its modular design, this scaffold adapts seamlessly to construction phases, from ground-level repairs to elevated plastering. The hot dip galvanized finish ensures longevity in corrosive environments, while the mobile base enables quick repositioning. Backed by online technical support and 3D model design, it streamlines project execution and reduces planning complexity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 500 kg/sqm | +15% (575 kg/sqm) | +30% (650 kg/sqm)* |

| Corrosion Resistance | Galvanized | Hot Dip Galvanized | Premium Coating (+40%) |

| Mobility | Manual Wheels | Semi-Automatic | Fully Motorized |

Technical Breakthroughs:

Version Selection Guidance:

Example: The Pro model’s 650 kg/sqm load capacity exceeds industry standards by 30%, making it safe for multi-worker operations. Paired with its fully motorized base, it reduces labor effort by 40%, boosting productivity on large-scale projects.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-stress construction sites | - Industry Standard: ASTM A36 steel (250 MPa yield strength) - Our Base: Q235 steel (235 MPa yield strength) - Our Advanced: Q345 steel (345 MPa yield strength) ▲▲ | Advanced grade (Q345) reduces deformation risks under heavy loads (e.g., industrial warehouses). | Base version may strain in extreme conditions (e.g., seismic zones). |

| Surface Treatment | Coastal/industrial corrosive environments | - Industry Standard: Painted coating (ASTM D3290, 20μm thickness) - Our Base: Painted (30μm) ▲ - Our Advanced: Hot-dip galvanized + painted (ISO 1461, 85μm zinc layer) ▲▲ | Advanced offers dual corrosion resistance (zinc + paint) for offshore projects. | Base coating may require recoating every 1–2 years in harsh conditions. |

| Safety Features | High-rise construction with fall risks | - Industry Standard: Basic diagonal bracing (EN 12811-1) - Our Base: Reinforced crossbars + diagonal bracing ▲ - Our Advanced: Anti-slip planks + load sensors ▲▲ | Advanced sensors alert users to unsafe load distribution (e.g., during crane lifts). | Base lacks real-time monitoring for dynamic load adjustments. |

| Mobility | Frequent repositioning in dynamic spaces | - Industry Standard: Fixed base scaffolds - Our Base: Casters with brakes (EN 131) ▲ - Our Advanced: Hydraulic elevation + omnidirectional casters ▲▲ | Advanced allows seamless height adjustments on uneven terrain (e.g., uneven urban sites). | Base casters may skid on slopes >15°. |

| Project Solutions | Complex projects needing pre-planning | - Industry Standard: Manual design drawings - Our Base: 2D graphic design support ▲ - Our Advanced: 3D modeling + BIM integration ▲▲ | Advanced streamlines coordination with architects (e.g., smart building projects). | Base lacks compatibility with BIM platforms like Revit. |

| Warranty | Long-term construction contracts | - Industry Standard: 1-year warranty - Our Base: 2-year warranty ▲ - Our Advanced: 3-year warranty + on-site support ▲▲ | Advanced includes priority repairs for critical infrastructure projects. | Base warranty excludes accidental damage (e.g., vandalism). |

⭐⭐⭐⭐⭐ James Carter - Senior Site Supervisor, UrbanBuild Contractors

"We’ve been using the Advanced Model of this scaffold across three mid-rise renovation projects since May 2024, and it’s been a game-changer. The hot-dip galvanized finish has held up perfectly through spring rains and summer humidity—zero signs of corrosion. Assembly time dropped by nearly 35% thanks to the modular interlocking design, and the semi-automatic mobility makes repositioning fast even on cluttered sites. The 3D model design service helped us pre-plan configurations down to the platform level, reducing on-site errors. OSHA compliance documentation was provided promptly, which made inspections seamless."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Emily Tran - Homeowner & Weekend DIYer

"I bought the Base Model for exterior plaster repairs on my two-story home last November. As someone with limited scaffolding experience, I was nervous about setup, but the graphic design guides were incredibly clear. The manual wheels made it easy to move around the yard, and the adjustable height meant I could work comfortably without overreaching. It feels solid—no wobbling even at full extension. My only note is that heavier tools (like a mortar mixer) require careful weight distribution, but that’s expected at this price point. For homeowners, it's a smart, safe upgrade over ladders."Purchase Date: November 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Carlos Mendez - Plant Maintenance Lead, Midwest Manufacturing

"Our facility needed a reliable scaffold for overhead pipe inspections in corrosive environments. We opted for the Pro Model in February 2025 due to its 650 kg/sqm load capacity and fully motorized base. Moving it across uneven concrete floors is effortless, and the premium coating has resisted chemical splashes and high moisture without issue. The load sensors give real-time feedback—critical when two technicians are working up top. The 3-year warranty with on-site support gives us peace of mind for long-term deployment. This isn’t just equipment; it’s an integrated safety solution."Purchase Date: February 2025 | Usage Period: 2 months

Posted: 5 days ago

"Used the Advanced Model for window frame upgrades on a 10-story building. The reinforced diagonal bracing kept everything stable in windy conditions. Setup with online tech support was smooth. Will definitely repurchase."

Posted: 12 days ago

"After a bad experience with generic scaffolds, we switched to the Pro Model. The dual surface treatment and motorized base have made daily operations safer and faster. Tech team responded within an hour to a configuration query—outstanding service."

Posted: 3 weeks ago

"I work solo most days and needed something portable and strong. The Base Model ticks both boxes. Wheels could be sturdier on gravel, but overall, it's reliable and easy to store."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.