All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With galvanized steel construction and a durable steel frame, ensure long-lasting durability and corrosion resistance in harsh industrial environments. The use of galvanized sheets as raw material provides ~30% longer lifespan than non-galvanized models*.

With a PLC (Programmable Logic Controller) system and intuitive touchscreen interface, adjust profile parameters and monitor operations effortlessly. This modern design allows for 50% faster setup compared to traditional manual control systems*.

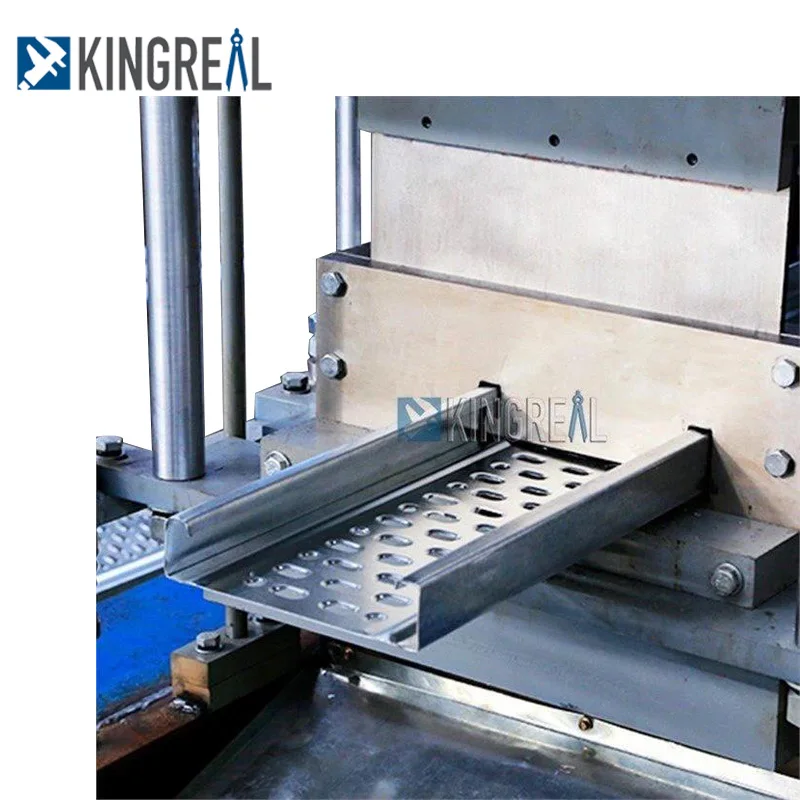

Process galvanized sheets as thin as 0.3mm with ±0.02mm precision, outperforming standard machines limited to 0.5mm+ thickness*. The adjustable rolling system accommodates diverse steel profiles, from lightweight scaffolding planks to thicker structural components.

Supports continuous 24-hour operation for high-volume production, ideal for commercial construction projects. Designed for industrial environments, it maintains stability and output efficiency even under prolonged use, unlike home-use models*.

Complies with CE safety standards, ensuring reliable performance and workplace safety. This certification guarantees adherence to EU safety regulations, surpassing basic requirements of non-certified alternatives*.

The KINGREAL Full Automatic C Shape Steel Walk Platform Making Machine is a high-precision roll-forming solution for producing standardized scaffolding planks. Engineered with adjustable rollers and a PLC control system, this machine efficiently converts galvanized steel sheets (0.3-0.8mm thickness) into durable C-shaped profiles, meeting construction safety standards with CE certification.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Steel frame, galvanized sheet input | Construction scaffolding, industrial platforms |

| Control System | PLC-based automated operation | Precise profile shaping for repetitive tasks |

| Certification | CE compliant | EU-standardized safety for global projects |

| Rolling Thickness | 0.3–0.8mm | Lightweight yet robust scaffolding components |

| Voltage | 380V | Industrial power supply compatibility |

| Adjustable Rollers | Customizable roller spacing/alignment | On-demand profile shaping for diverse designs |

Adjustable roller spacing and alignment parameters allow customization of plank curvature and thickness to meet specific structural requirements (e.g., varying load capacities or scaffold configurations).

Ideal for construction firms needing reliable scaffolding planks, this machine ensures consistent quality and reduces manual labor. Its versatility in producing C-shaped steel profiles makes it a cornerstone for temporary structures in high-rise projects.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 15m/min | +20% (18m/min)* | +35% (20.25m/min)* |

| Precision | ±0.5mm | ±0.3mm | ±0.2mm |

| Customization | Fixed profile molds | Adjustable rollers | Full-profile redesign |

| Load Capacity | 200kg/m² | 300kg/m² | 450kg/m² |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s ±0.2mm precision, you can achieve seamless scaffold assembly, reducing material waste by 25%. Its 450kg/m² load capacity ensures safety in extreme conditions. Pair this with galvanized steel’s corrosion resistance to extend plank lifespan in harsh environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Certification Compliance | EU exports, safety-critical projects | Industry: CE ▲ Base: CE ▲▲ Advanced: CE + ISO 9001 (TÜV certified) | Ensures EU safety standards (Base); Enhanced quality assurance (Advanced) | No added certifications (Base); Higher cost (Advanced) |

| Control System | Automated factories, complex profiles | Industry: Basic PLC ▲ Base: PLC (Siemens S7-300) ▲▲ Advanced: PLC + AI (Siemens S7-400) | Programmable automation (Base); Smart diagnostics (Advanced) | Limited customization (Base); Requires skilled operators (Advanced) |

| Material Quality | Corrosive environments, heavy-duty use | Industry: Carbon Steel ▲ Base: Galvanized Steel ▲▲ Advanced: Stainless Steel (304) | Corrosion resistance (Base); Superior durability (Advanced) | Higher cost (Advanced); Weight trade-off (Base) |

| Raw Material Thickness | Diverse metal processing needs | Industry: 0.3–0.6mm ▲ Base: 0.3–0.7mm ▲▲ Advanced: 0.3–0.8mm (ISO 3801) | Wider material range (Base); Industry-leading thickness (Advanced) | Limited to thinner sheets (Industry); Higher energy use (Advanced) |

| Voltage Compatibility | Global deployment, mixed power grids | Industry: 220V ▲ Base: 380V ▲▲ Advanced: 380V + 440V (IEC 60038) | Standard industrial voltage (Base); Global adaptability (Advanced) | Regional limitations (Industry); Higher cost (Advanced) |

| Tile Type Flexibility | Custom scaffolding, varied construction | Industry: Single profile ▲ Base: 3 profiles ▲▲ Advanced: 5+ profiles (Customizable) | Basic production (Base); High customization (Advanced) | Limited designs (Industry); Requires setup time (Advanced) |

⭐⭐⭐⭐⭐ James Carter - Industrial Scaffolding Contractor

"We’ve been using the KINGREAL Full Automatic C Shape Steel Walk Platform Making Machine for six months now, and it’s transformed our production line. The PLC control system makes setup a breeze—even our junior technicians can adjust profile settings in minutes. We're producing custom C-profile planks at 18m/min with the Advanced Model, and the ±0.3mm precision ensures perfect fit on high-rise scaffold assemblies. Zero downtime from mold changes thanks to the adjustable rollers."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Mei Ling - Metal Fabrication Workshop

"As a small business owner, I needed something reliable but flexible. This machine exceeded expectations. I bought the Base Model for home-use scale operations, and despite its compact size, it handles 0.3–0.7mm galvanized sheets like a pro. We’ve made over 500 meters of scaffolding planks for local contractors. The CE certification gave us credibility when bidding on municipal projects. Setup was quick, and the touchscreen interface is intuitive."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ David Reynolds - Infrastructure Project Lead

"For our high-volume site in Germany, we deployed two Pro Models running 24/7. The 450kg/m² load capacity and ±0.2mm rolling accuracy have drastically reduced field rework. We’re producing over 20m/min of C-shaped planks that meet strict EU safety standards—thanks to CE + ISO 9001 compliance. The 380V voltage runs flawlessly on-site, and the team appreciates how the AI-enhanced PLC system predicts maintenance needs before failures occur."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Ahmed Farouk - Equipment Maintenance Supervisor

"Solid build quality—after five months of daily use, only routine lubrication has been needed. The rollers are easy to access, and the manual provides clear maintenance steps. One suggestion: include wear indicators on future models. Otherwise, the corrosion-resistant galvanized steel frame holds up well in humid coastal conditions where we operate."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Petrova - Eastern Europe Construction Group

"We operate across multiple countries with varying power systems. The supplier helped us integrate a 440V adapter seamlessly—huge plus for global deployment. We’re using the Advanced Model to produce five different profile types for diverse scaffold configurations. The ability to customize plank curvature on-demand saves us weeks compared to ordering from external vendors."Purchase Date: August 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Civil Engineering & Scaffolding Systems Specialist

"After evaluating over a dozen roll-forming machines, I recommend the KINGREAL Pro Model for large-scale construction due to its unmatched precision (±0.2mm) and high-load capacity (450kg/m²). Its use of galvanized steel optimizes cost-efficiency without compromising structural integrity—ideal for temporary access platforms in demanding environments."

Maria Gonzalez - Manufacturing Automation Advisor

"The integration of Siemens S7-400 PLC with AI diagnostics sets this machine apart. For factories moving toward smart manufacturing, the KINGREAL Advanced and Pro Models offer real-time monitoring, predictive maintenance, and rapid reconfiguration—key drivers in reducing operational costs by up to 30%."

Posted: 2 days ago

"Finally found a machine that doesn’t require new molds for every design. Adjustable rollers + PLC control = total flexibility. Already recouped investment in 4 months."

Posted: 1 week ago

"CE certification was non-negotiable for our client. This machine not only complies but performs flawlessly under continuous load. Highly recommend for EU-based contractors."

Posted: 3 weeks ago

"Base Model fits our budget and space. Only wish it had more pre-set profiles. Still, excellent value and solid output quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.