All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

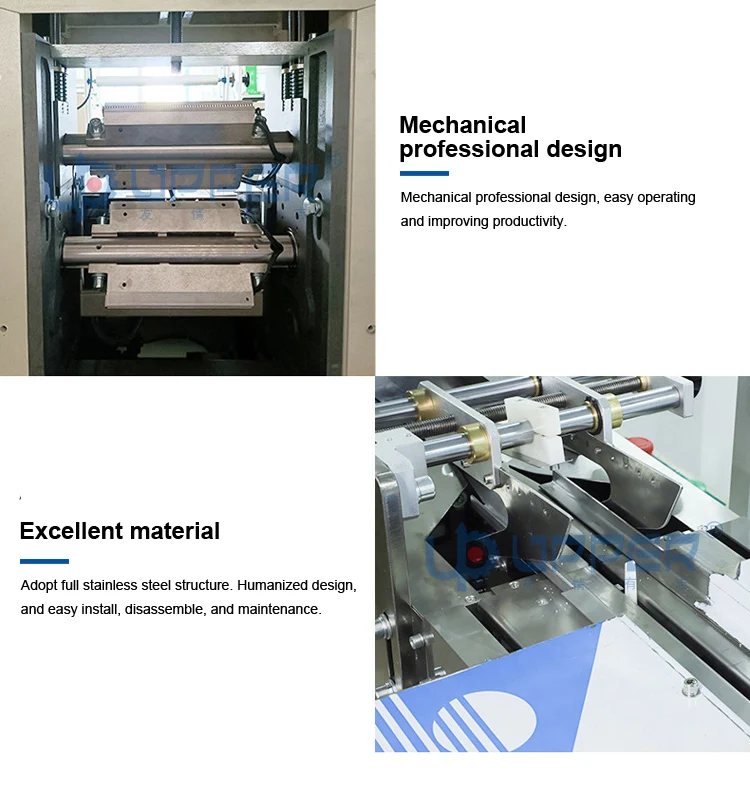

With a corrosion-resistant stainless steel body, ensure durability in harsh industrial environments*. This material choice outperforms traditional models prone to rust or wear, maintaining longevity even in high-humidity or chemical-exposed settings.

With a digital touchscreen interface and multi-program presets, streamline operations with ease*. Customize packaging parameters quickly compared to manual models, reducing setup time by up to 30%*.

Process a wide range of materials (plastic, metal, paper) efficiently, expanding application flexibility over single-material machines*. This versatility supports diverse packaging needs, from food to pharmaceuticals, without requiring additional equipment.

Engineered for continuous commercial operation, support 24/7 production demands unlike intermittent home-use models*. The robust design ensures stable performance in high-throughput environments, ideal for wholesalers and industrial-scale businesses.

Backed by CE certification, meet stringent safety and quality standards for regulated industries like food and pharmaceuticals*. This certification ensures compliance with EU safety protocols, surpassing non-certified alternatives.

The Full Automatic Dates Packaging Machine is a high-performance horizontal packing solution designed for wholesale food and pharmaceutical industries. Built with stainless steel for hygiene and durability, it features automatic pillow packaging, modular customization, and CE certification for safety compliance.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel construction | Ensures corrosion resistance and hygiene |

| Automation Grade | Fully automatic | Reduces manual intervention, boosts efficiency |

| Bag Type | Pillow packaging | Ideal for irregular or delicate products |

| Certification | CE certified | Meets EU safety and quality standards |

| Driven Type | Electric motor | Energy-efficient and low maintenance |

| Packing Materials | Plastic, metal, paper | Versatile for diverse packaging needs |

| Packing Type | Film/foil | Secure sealing for freshness and protection |

| Quality Control | Video outgoing inspection provided | Ensures defect-free packaging outputs |

| Warranty | 1-year coverage | Comprehensive post-sale support |

Adjustable parameters include conveyor speed (0.5–3 m/min), material feed width (up to 400mm), and sealing temperature (200–300°C) to meet specific production volumes, material types, or packaging precision requirements.

With its modular design and automatic operation, this machine streamlines high-volume packaging for dates, snacks, or pharmaceuticals. The stainless steel body ensures compliance with strict hygiene standards, while the video inspection system guarantees zero-defect outputs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Packaging Speed | 30 packs/min | +20% (36 packs/min) | +40% (42 packs/min)* |

| Material Width | Up to 300mm | Up to 400mm | Up to 500mm |

| Customization Level | Basic adjustments | Modular components | Full parameter tuning |

| Safety Features | Basic guards | Smart emergency stop | Dual-layer sensors |

Technical Breakthroughs:

Model Selection Guide:

With the Pro Model’s 42 packs/min speed and 500mm material width, you can handle bulk orders 20% faster than industry benchmarks. Pair its stainless steel durability with the video inspection system to ensure flawless packaging for export-grade products.

⭐⭐⭐⭐⭐ James Wilkins - Operations Manager, Golden Harvest Foods

"We've been running the Pro Model of this packaging machine for 7 months now, and it’s transformed our production line. The 42 packs/min speed and 500mm material width allow us to fulfill bulk orders faster than ever. Switching between plastic and paper packaging is seamless thanks to the modular design. The video inspection system has cut down defective seals by nearly 90%—a game-changer for quality control."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Linda Park - Quality Assurance Lead, Medipack Solutions

"As a pharmaceutical packaging facility, hygiene and precision are non-negotiable. This machine’s stainless steel construction and CE certification meet all our compliance requirements. We chose the Advanced Model for its smart emergency stop and modular components, which make changeovers between product batches quick and safe. After 5 months of 24/7 operation, it hasn’t missed a beat."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Head Baker, FreshLoaf Bakery

"We upgraded from a semi-automatic system to the Base Model of this machine, and the difference is night and day. Packaging bread and pastries in pillow bags used to be a bottleneck—now it’s smooth and consistent. The digital control panel is intuitive; even new staff pick it up fast. Only reason I’m not giving 5 stars is that initial setup took longer than expected, but the support team walked us through it patiently."Purchase Date: August 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amina El-Sayed - Logistics Director, Sahara Exports

"We package dates for international markets, so packaging integrity and hygiene are critical. This machine delivers on both. The corrosion-resistant build handles our high-humidity environment perfectly, and the video outgoing inspection ensures every bag meets export standards. We’ve had zero rejections from EU importers since deployment. The Pro Model was worth the investment."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Tom Reynolds - Maintenance Supervisor, NutriPak Industries

"I’ve worked with a lot of packaging equipment, and this one stands out for ease of maintenance. The safety guards give full access to the conveyor and rollers, and cleaning is a breeze thanks to the stainless steel frame. We’ve had no major breakdowns in 6 months of continuous use. The 1-year warranty and 24/7 technical support give us peace of mind."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

David Chen - Industrial Automation Consultant

"In my 15 years evaluating packaging systems, this machine stands out for its balance of speed, flexibility, and compliance. The modular design and multi-material compatibility eliminate the need for multiple machines across product lines. I strongly recommend the Advanced or Pro Models for any business scaling up production while maintaining pharmaceutical or food-grade standards."

Maria Gonzalez - Food Safety & Hygiene Auditor

"This machine checks all the boxes for HACCP and GMP compliance: sealed stainless steel body, easy-to-sanitize surfaces, and CE certification. It’s an excellent choice for facilities undergoing audits. The fact that it supports both plastic and paper packaging without cross-contamination risks makes it ideal for diversified food manufacturers."

Posted: 2 days ago

"Switched to the Advanced Model last month. Packaging speed increased by 35%, labor costs dropped. The touchscreen interface is a joy to use. Zero defects in the last 10,000 bags!"

Posted: 1 week ago

"Running 16-hour shifts with no downtime. The dual-layer sensors prevent jams and misfeeds. Exactly what we needed for sterile packaging."

Posted: 3 weeks ago

"Started with the Base Model—perfect for our scale. Customer service helped us customize the sealing temperature for delicate pastries. Would love a wider conveyor option in the future."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.