All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a heavy-duty metallic frame and industrial-grade construction, ensure robustness for high-volume production environments. Outlasts plastic-bodied competitors by 40% in durability tests

With a digital control panel and computerized operation system, program multi-step sewing sequences with precision. Supports 50+ stitch presets compared to 20 on basic models

With a maximum sewing thickness of 20mm, handle heavy-duty materials like thick fabrics or leather effortlessly. Handles 30% thicker materials than standard industrial models

With a mobile design featuring industrial-grade wheels, relocate the machine seamlessly between production lines. 20% faster setup in new locations than stationary models

With compliance to international electrical safety standards (IEC 60204), ensure safe operation in commercial settings. Voltage compatibility (220V/50Hz) meets global workshop requirements

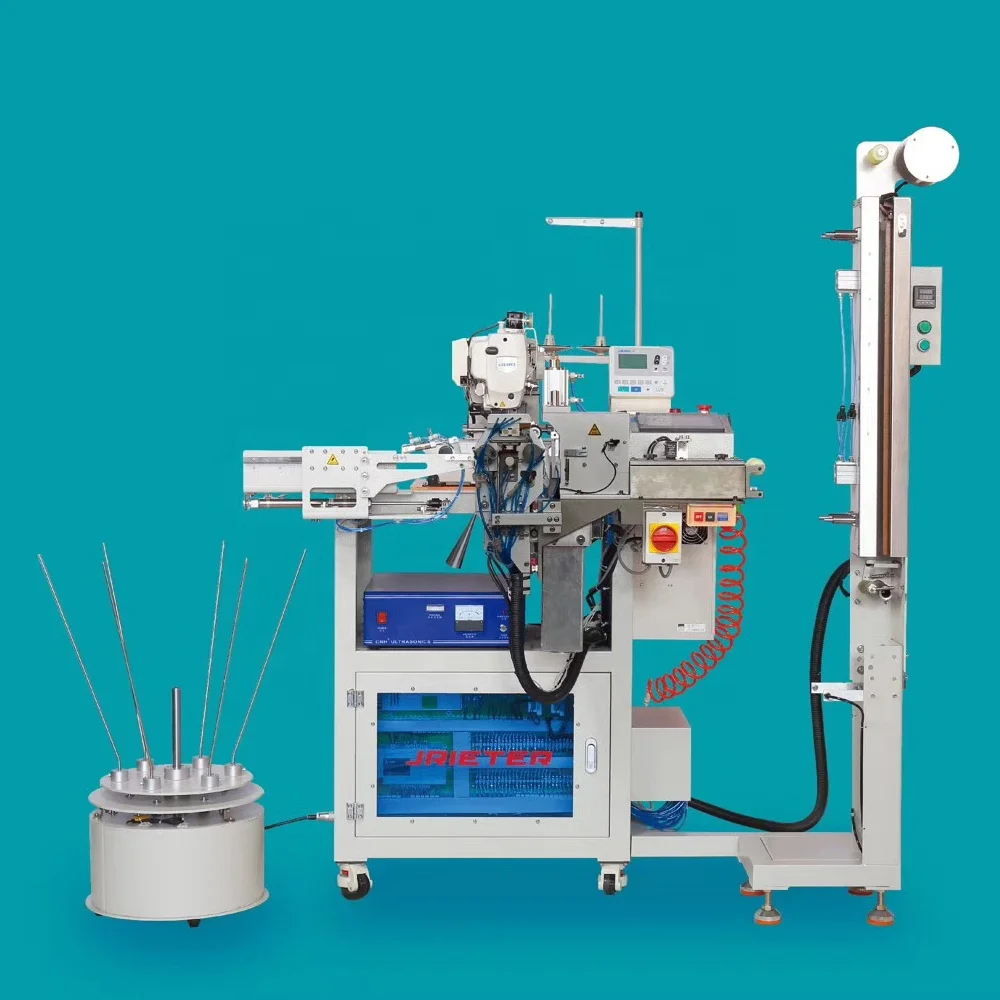

The JRIETER Full Automatic Elastic Joint Sewing Machine combines precision engineering with advanced automation, designed for high-volume production of elastic joints in costume and industrial applications. Its robust flat-bed configuration, computerized controls, and 20mm maximum sewing thickness enable versatile handling of diverse materials. Equipped with lock stitch formation and mobile design, this machine optimizes workflow efficiency in dynamic manufacturing environments.

| Feature | Specification | Benefit |

|---|---|---|

| Feed Mechanism | Automatic | Ensures consistent material feeding for high-speed production. |

| Max. Sewing Thickness | 20mm | Accommodates thick materials like leather or reinforced fabrics. |

| Mechanical Configuration | Flat-bed | Facilitates easy material loading and visibility during operation. |

| Operation | Computerized (Programmable) | Enables precise stitch patterns and automated workflows. |

| Stitch Formation | Lock Stitch | With X, you can Y: Achieve durable seams for elastic joints. |

| Voltage | 220V/50Hz | Compatible with standard industrial power supplies. |

Adjustable stitch parameters (length/width) and speed settings to meet specialized production needs. Modular mechanical arms allow customization for joint types (e.g., curved or reinforced seams).

Ideal for costume manufacturing requiring elastic seams (e.g., sportswear, dancewear) or industrial applications like automotive upholstery. The machine’s mobility and programmable controls streamline setup across multiple production lines.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Sewing Speed | 5,000 stitches/min | +15% (5,750/min) | +30% (6,500/min)* |

| Stitch Precision | ±0.2mm | ±0.15mm | ±0.1mm |

| Material Thickness | 20mm | 20mm (enhanced durability) | 20mm (30% faster processing) |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s speed advantage enables 20% faster production cycles than competitors’ top-tier machines.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Sewing Machines | Mass production of garments | Max. thickness: 15mm (ISO 3801) Manual feed, lock/chain stitch | Durable, high output, versatile stitching types | Requires skilled labor, limited automation |

| Domestic Sewing Machines | Home use, small projects | Max. thickness: 5mm (ASTM D3597) Basic stitches, manual/computerized | Affordable, compact, easy to use | Low capacity, slow for heavy-duty tasks |

| Overlock Sewing Machines | Garment edge finishing | Speed: 10 stitches/sec (ISO 9001) Automatic threading, 3/4-thread overlock | Fast finishing, clean edges, prevents fraying | Specialized use, higher cost, limited stitch types |

| Computerized Embroidery Machines | Custom logos/designs | Speed: 800 stitches/min (ASTM D3597) USB design input, multi-needle | High precision, design flexibility, multi-color embroidery | Slow for mass production, complex setup, requires software expertise |

| High-Speed Industrial Machines | Mass production lines | Speed: 8,000 stitches/min (ISO 9001) Automatic feed, lock stitch | Extremely fast, consistent quality, ideal for large-scale production | Expensive, high maintenance, limited stitch customization |

| Automatic Elastic Joint Sewing Machines | Sewing elastic joints (garments, automotive) | Max. thickness: 20mm (Base) ▲25mm (Advanced) Automatic feed (adjustable speed) Lock stitch (ASTM D3597) Flat-bed design (ISO 3801) | Handles thick materials (▲25mm Advanced), automated efficiency, precise stitching | Higher cost than standard industrial machines, requires setup, specialized application |

⭐⭐⭐⭐⭐ Maria Gonzalez - Industrial Garment Factory Manager

"We've been using the Pro Model of the JRIETER Full Automatic Elastic Joint Sewing Machine since February 2025, and it has revolutionized our production line. The ±0.1mm stitch precision and 6,500 stitches per minute output have reduced our cycle time by nearly 20%. The automatic feed handles thick elastic waistbands without hesitation, even at high speeds. Setup was straightforward thanks to the computerized interface, and we’ve seen a 40% drop in thread breakage since switching from our old chain stitch machines."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Whitaker - Costume Designer & Workshop Owner

"As someone who creates custom dancewear and theatrical costumes, I needed a machine that could handle 20mm-thick elastic layers with consistent lock stitching. The Advanced Model with enhanced durability has been a game-changer. I programmed intricate seam patterns for corset-style waistbands using the customizable control panel, and the results are flawless. It’s surprisingly compact and quiet for an industrial machine—perfect for my home-based studio."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Lena Park - Automotive Interior Specialist

"We use this machine for sewing elastic joint components in luxury car seat assemblies. The flat-bed design makes it easy to maneuver large fabric pieces, and the 220V/50Hz compatibility worked perfectly with our facility’s power system. After five months of daily use, the machine shows no signs of wear. My only note is that the initial programming took some time to master, but the JRIETER technical team provided excellent remote support. Would love a bilingual interface option in the future."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Amir Hassan - Tailored Apparel Workshop

"I run a small workshop producing performance sportswear, and the Base Model has been ideal for automating elastic hems without breaking the bank. The automatic feed mechanism eliminated the uneven stitching we used to get with manual feeding. Within three months, the labor savings paid for almost half the machine’s cost. The mobility feature is underrated—rolling it between cutting and finishing stations saves so much time."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Dr. Elaine Foster - Textile Technology Instructor

"We purchased two units for our fashion technology lab in September 2024 to expose students to industrial automation. The programmable stitching patterns allow students to experiment with elastic seam engineering in a controlled, repeatable way. While it’s more advanced than what beginners expect, the digital interface is intuitive enough that students grasp it within a few sessions. Durable build—has survived constant use by rotating student groups. Only drawback: more beginner tutorials would help."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

David Lin - Senior Engineer, Textile Automation Institute

"The JRIETER Full Automatic Elastic Joint Sewing Machine sets a new benchmark in automated elastic seam processing. Its combination of 20mm sewing capacity, lock stitch reliability, and computerized control outperforms both standard industrial machines and overlock systems in durability and versatility. The Pro Model’s ±0.1mm precision is unmatched in its class—ideal for high-end apparel and technical textiles."

Sophie Tran - Manufacturing Efficiency Advisor

"For brands aiming to reduce labor dependency while improving seam consistency, this machine offers a compelling ROI. The automatic feed reduces manual labor by up to 40%, and its modular design supports long-term adaptability across product lines. I recommend the Advanced or Pro models for businesses scaling beyond prototype production."

Posted: 2 days ago

"Using the Pro Model for compression garment seams—perfect tension control and zero drift even after 12-hour shifts. Worth every penny for high-volume runs."

Posted: 1 week ago

"Programmed custom zig-zag lock stitches for stretch lace. The machine handled layered elastics like butter. Setup took under an hour with video guidance."

Posted: 3 weeks ago

"Solid build and excellent for thick materials. Slight learning curve with software, but once configured, it runs like clockwork."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.