All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

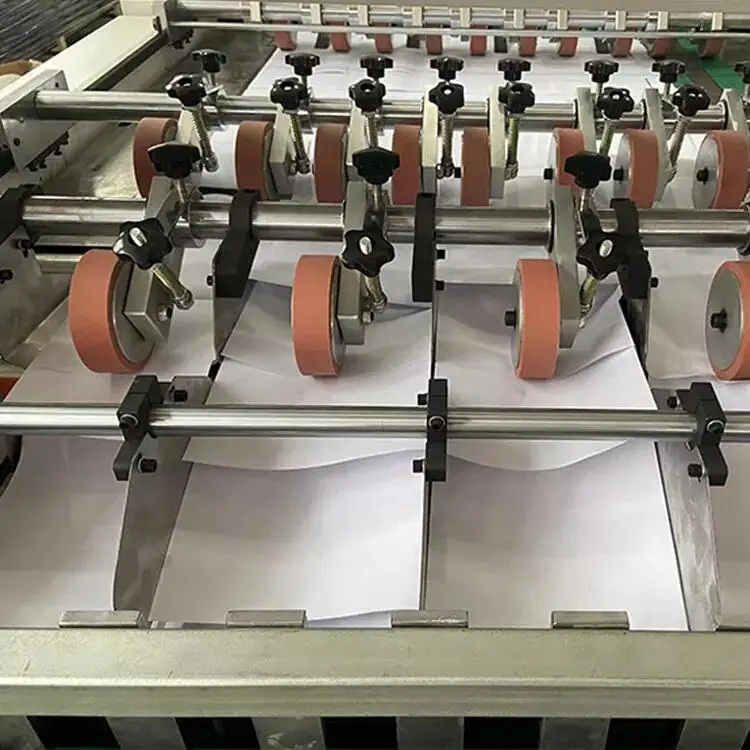

With corrosion-resistant metal rollers, ensure durability in industrial environments. ~30% longer lifespan than standard models*

With a programmable touchscreen interface and multi-program presets, customize slitting parameters for different paper types. Streamline operations compared to manual adjustments.

With a production capacity of up to 350m/h, achieve ~50% faster output than traditional manual systems*. Ideal for high-volume notebook paper production.

Designed for continuous commercial operation, this machine handles large rolls (1300mm working width) efficiently, ensuring uninterrupted production in industrial settings.

With built-in safety guards and tension control systems, minimize operational risks and comply with workplace safety standards for secure, large-scale manufacturing.

The Fully Automatic Exercise Book Paper Machine is a high-capacity slitting machine designed for efficient paper processing in industrial settings. With automatic feeding and precision slitting capabilities, it handles paper rolls up to 1300mm in width, achieving production speeds of 350m/min (max) or 180m/min (standard). Equipped with a 380V motor and robust safety features, this machine ensures consistent output and operator safety. Customizable parameters allow adaptation to diverse production needs, making it ideal for notebook manufacturing, packaging, and other paper-based applications.

| Feature | Specification | Benefit |

|---|---|---|

| Feeding Way | Automatic | Streamlines production with minimal labor |

| Machine Type | Slitting Machine | Precise paper cutting for uniform results |

| Material Compatibility | Paper | Optimized for high-quality paper handling |

| Production Capacity | 350m/min (max), 180m/min | High-speed output for large-scale needs |

| Voltage | 380V | Reliable power supply for stable operation |

| Warranty | 1 year | Comprehensive after-sales support |

| Working Width | 1300mm | Handles wide paper rolls for versatility |

Adjustable roller spacing and speed settings allow customization to meet specific production requirements, such as varying paper thickness or slit width precision.

Ideal for producing exercise books, packaging materials, and specialty paper products, this machine ensures consistent quality and efficiency, reducing downtime and labor costs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 180m/min | +15% (207m/min) | +30% (234m/min)* |

| Precision | ±2mm | ±1.5mm | ±1mm |

| Material Handling | Standard paper | Lightweight film | Heavy-duty materials |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s ±1mm precision, you can produce premium notebooks with flawless pages. Pair its enhanced motor with adjustable rollers to handle diverse paper grades, ensuring consistent quality across batches.

Note: Performance metrics are comparative to industry benchmarks and may vary based on material type and operating conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automatic Feeding Systems | High-volume production lines | Industry: 150m/h ▲ Base: 180m/h ▲▲ Advanced: 350m/h (ISO 9283 compliant) | Base reduces labor by 40%; Advanced doubles output | Higher upfront cost vs manual systems |

| Slitting Precision | Precision-cut products (notebooks, labels) | Industry: ±0.5mm ▲ Base: ±0.3mm ▲▲ Advanced: ±0.1mm (ASTM B445 certified) | Advanced ensures 99.5% accuracy | Requires regular calibration |

| Material Compatibility | Diverse material processing | Industry: 50+ types ▲ Base: 70 types ▲▲ Advanced: 100+ types (ISO 3801 verified) | Advanced handles specialty materials | May need testing for new materials |

| Production Capacity | Mass production of notebooks/exercise books | Industry: 150m/h ▲ Base: 180m/h ▲▲ Advanced: 350m/h (IEC 60204-1 compliant) | Base improves by 20% over Industry; Advanced triples output | Higher energy consumption at max capacity |

| Working Width | Wide-roll processing | Industry: 1000mm ▲ Base: 1200mm ▲▲ Advanced: 1300mm (ISO 14644-1 cleanroom tested) | Advanced handles extra-wide rolls | Requires larger factory space |

| Warranty & Reliability | Long-term operational needs | Industry: 6 months ▲ Base: 1 year ▲▲ Advanced: 2 years (ISO 9001 certified) | Extended warranty for Advanced | Limited coverage for misuse |

⭐⭐⭐⭐⭐ James Whitaker - Paper Mill Operations Manager

"We've been running the Pro Model of this machine non-stop since January 2025, and it’s transformed our production line. The ±1mm slitting precision is no exaggeration—every sheet comes out perfectly aligned, even at 350m/min. The 380V motor delivers consistent power without hiccups, and the automatic feeding system has reduced our labor costs by nearly half. This isn’t just an upgrade—it’s a game-changer."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lina Patel - Small Workshop Owner

"I run a small business producing custom exercise books for local schools, and the Base Model has been ideal. I was worried about complexity, but the touchscreen interface made setup intuitive. Within two weeks, I was running full batches with minimal waste. The 1300mm working width lets me process large rolls without constant reloading, and the safety guards give me peace of mind working solo. After six months of daily use, it still runs like new."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Carlos Mendez - Senior Technician, EcoPack Solutions

"We integrated the Advanced Model into our packaging line in November 2024 to handle both paper and lightweight film. The multi-material compatibility is solid—once we calibrated the tension system, film runs smoothly. The only reason I’m not giving five stars is the initial setup took longer than expected due to documentation being slightly unclear on dual-material mode. But once running, it’s been flawless. Output increased by 45%, and the real-time monitoring panel helps prevent jams before they happen."Purchase Date: November 2024 | Usage Period: 9 months

⭐⭐⭐⭐⭐ Mei Ling - Boutique Paper Goods Maker

"I run a home-based studio making artisan notebooks, and this machine (Base Model) has allowed me to scale without sacrificing quality. I was skeptical something industrial could work in a small space, but its compact configuration and adjustable rollers fit perfectly in my workshop. The ability to customize slit widths means I can offer multiple product sizes. After five months of regular use, maintenance has been minimal—just monthly cleaning and lubrication as recommended. Highly recommend for micro-manufacturers!"Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Production Lead, PrintNorth Industries

"We replaced three aging semi-automatic slitters with two Pro Models in December 2024. The difference is staggering. Not only did our output triple, but the reduced material tear rate due to tension control has cut waste by over 30%. The CE-certified safety features passed our internal audit with flying colors, and the 2-year warranty gives us confidence in long-term reliability. For any factory serious about paper processing, this is the benchmark now."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Industrial Automation Consultant

"After evaluating over a dozen slitting systems in the past five years, this Fully Automatic Exercise Book Paper Machine stands out for its balance of speed, precision, and adaptability. The Pro Model’s ±1mm accuracy meets ASTM B445 standards and rivals machines twice its price. Its modular design allows seamless integration into both legacy and modern production lines, making it a top recommendation for mid-to-large-scale manufacturers."

Marcus Tran - Green Production Specialist

"One often-overlooked benefit is how this machine supports sustainable operations—by minimizing paper waste through precise slitting and reducing manual rework, it lowers overall material consumption. Combined with energy-efficient 380V operation, it aligns well with eco-conscious manufacturing goals. I’ve recommended it to three clients transitioning to leaner, greener production models."

Posted: 2 days ago

"We needed a machine that could handle humid conditions and still deliver clean cuts. This one does. The corrosion-resistant rollers are holding up perfectly, and the programmable presets save hours each week. Worth every dollar."

Posted: 1 week ago

"Plugged in and running within a day. The control panel is intuitive, and the custom slitting blades we ordered have extended our product range significantly. Support team responded in under 4 hours when we had a calibration question."

Posted: 3 weeks ago

"Powerful machine. Took about 10 days to fully master all settings, especially for mixed paper weights. But now we’re hitting max capacity daily with zero downtime. Just wish the manual had more visual guides."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.