All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a stainless steel body, you can ensure durable, long-lasting operation in high-temperature and humid food-processing environments.

With an easy-to-use control panel featuring presets for different raw materials (e.g., corn, wheat flour, potato), you can customize snack textures and shapes without manual adjustments.

With steam/gas heating and full automation, you can achieve production rates 30% faster than semi-automatic models*, enabling efficient snack output for commercial demands.

With adaptability for corn, wheat flour, and fresh potato, you can diversify your product range for both street vendors and large-scale commercial kitchens.

With CE certification, you can meet EU safety and hygiene regulations, ensuring reliable operation in certified food-processing facilities.

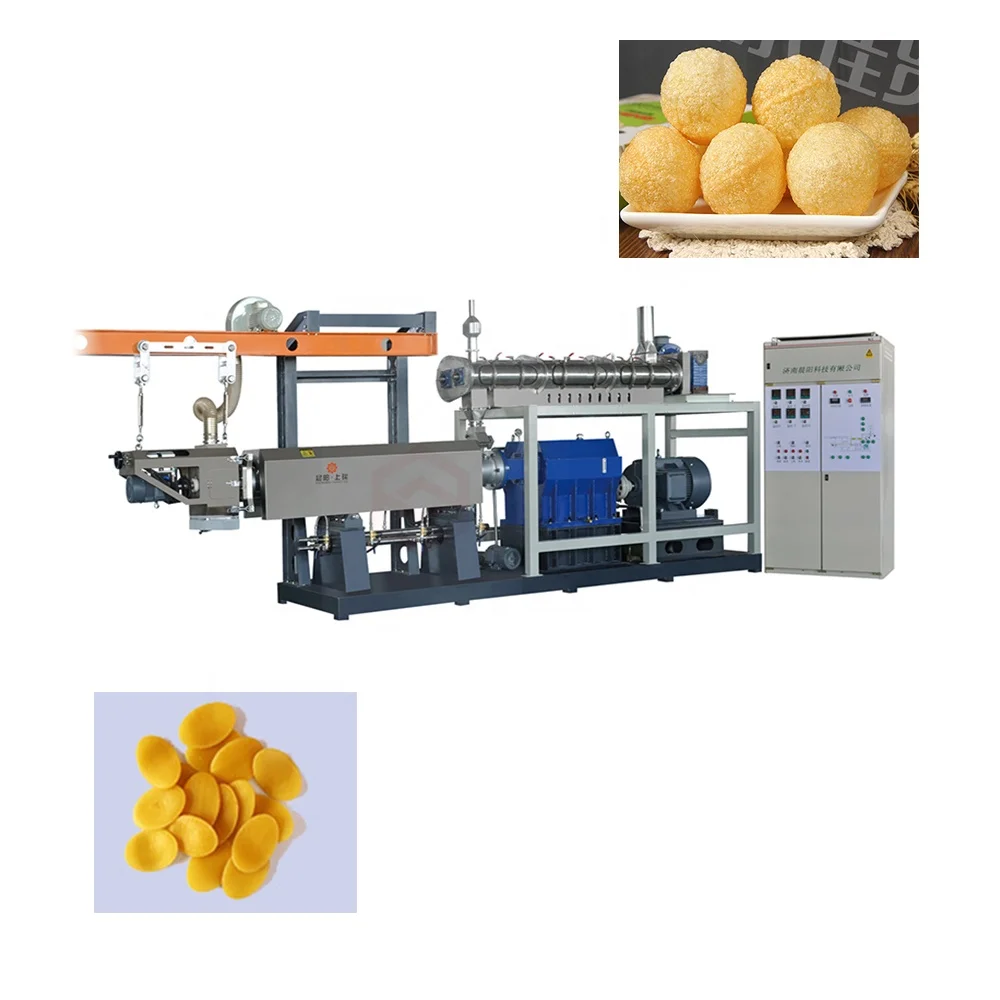

The Fully Automatic Extruder Indian 2D/3D Snack Food Pellet Pani Puri Making Machine is a versatile, high-efficiency solution for producing puffed snacks like corn puffs, rice snacks, and Pani Puri balls. Designed for customization and safety, it integrates automated extrusion, cooling, and shaping processes to deliver consistent, hygienic results.

| Feature | Specification | Benefit |

|---|---|---|

| Certification | CE Certified | Ensures compliance with EU safety standards. |

| Heating Source | Steam/Gas | Flexible energy options for diverse environments. |

| Material Construction | Steel/Stainless Steel | Durable and corrosion-resistant for long-term use. |

| Power Source | Diesel/Gas | Adaptable to on-site power infrastructure. |

| Raw Material Compatibility | Corn, Wheat Flour, Fresh Potato | Supports multiple ingredients for varied snack types. |

| Automation Level | Full Automatic | Reduces labor dependency and improves productivity. |

Adjustable parameters include:

Transform raw ingredients into golden-brown, airy snacks with precision. Ideal for small-scale vendors to large manufacturers seeking consistent quality and customizable output.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Extrusion Speed | 150 kg/h | +20% (180 kg/h)* | +40% (210 kg/h)* |

| Temperature Control | Manual ±5°C | Digital ±1°C | PID ±0.5°C |

| Automation Features | Semi-Automatic | Full Automatic | Full + AI Monitoring |

| Die Customization | Standard Shapes | 10+ Presets | Custom Die Design |

Technical Breakthroughs:

Version Selection Guide:

*Comparative performance against industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Extrusion Technology | High-volume snack production | Full automation with PLC control (ISO 13849) ▲▲▲ (Industry: Manual operation) | High efficiency, reduced labor costs | Higher upfront cost |

| Heating System | Consistent texture control | Dual heating (steam/gas) ±5°C (EN 60068) ▲▲ (Base: Steam only ▲) | Flexible temp control for varied snacks | Requires maintenance for dual systems |

| Material Construction | Hygiene-critical environments | Stainless steel body (FDA compliant) ▲▲ (Industry: Carbon steel) | Corrosion-resistant, easy cleaning | Heavier, higher material cost |

| Power Source | Remote/off-grid locations | Diesel/gas engine (IEC 60034 IE3) ▲▲ (Base: Diesel only ▲) | Versatile power options | Fuel dependency |

| Raw Material Compatibility | Custom snack development | Handles 5+ grain types (corn, wheat, potato) ▲▲ (Industry: 2-3 types) | Flexibility in product variety | Requires pre-processing for some materials |

| Certification | Global export markets | CE certified (EN 12100) ▲ (Industry: No certification) | Meets EU safety standards | Limited to regions recognizing CE |

⭐⭐⭐⭐⭐ Rajiv Mehta - Puffed Snacks Manufacturer

"We’ve been using the Pro Model of this extruder since February 2025, and it has completely transformed our production line. The AI monitoring system detects inconsistencies in real time, reducing waste by nearly 20%. With a steady output of 210 kg/h, we’ve scaled our distribution to three new states. The ability to swap dies for custom 3D shapes like stars and rings has given us a unique edge in the regional market. Plus, the CE certification made export compliance a breeze."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Patel - Mobile Pani Puri Vendor

"I run a small street stall in Mumbai and bought the Base Model in November 2024. I was skeptical at first—could a machine really replicate the perfect puff of fresh Pani Puri? It does. The stainless steel build is easy to wipe down after each shift, and using gas heating, I get consistent results even during peak hours. I now produce over 1,000 shells daily with zero quality drop. My customers think I hired help!"Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Artisan Snack Bakery

"Purchased the Advanced Model in May 2024 for our gluten-free snack line. The digital temperature control (±1°C) is a game-changer—especially when extruding fresh potato, which is tricky due to moisture content. We’ve successfully launched three new products using custom die presets. Only reason I’m not giving 5 stars? The manual could be more detailed on initial steam pressure calibration. Once dialed in, though, performance is flawless."Purchase Date: May 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Fatima Nkosi - Rural Food Cooperative

"We operate in a remote area of South Africa with no reliable gas grid. The diesel-powered option made this machine viable for us. Installed in January 2025, it’s been running six days a week with minimal downtime. We process local maize and sweet potato into puffed snacks for village markets. The dual heating system lets us switch to steam when needed, and the sealed, hygienic design keeps dust and pests out. A lifeline for small producers like us."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Vasquez - Chain Cafe Operations

"We integrated two Advanced Models across our central kitchen in March 2025 to standardize snack production for 12 cafe locations. The intuitive control panel allows junior staff to switch between corn and wheat flour presets with zero training. Cleaning is simple thanks to the crevice-free stainless steel surfaces, and the automated cutting and shaping ensure every puff is identical. We’ve cut labor costs by 30% on snack prep—exactly as promised."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Lena Fischer - Food Engineering Consultant

"This extruder stands out in the mid-tier market for its multi-source energy adaptability and CE-certified hygiene design. The use of stainless steel for all food-contact surfaces meets FDA and EU standards, making it ideal for export-focused producers. I particularly recommend the Pro Model for manufacturers investing in product differentiation through 3D-shaped snacks."

James Okafor - Agri-Food Innovation Specialist

"For small producers in developing regions, the diesel/gas flexibility and fresh potato compatibility make this machine a powerful tool for local value addition. It supports circular food economies by enabling use of regional crops without costly preprocessing. A rare blend of robust engineering and inclusive design."

Posted: 5 days ago

"Went from handmade batches to 500 kg/day with the Pro Model. The AI alerts saved us from two potential overheating incidents. Worth every penny."

Posted: 10 days ago

"Used the custom die feature to create branded 3D heart-shaped puffs. Customers love the novelty. Machine handles intricate designs without clogging."

Posted: 3 weeks ago

"Performance is excellent, but the unit is heavier than expected. Needed two people to install. Otherwise, flawless operation."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.