All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

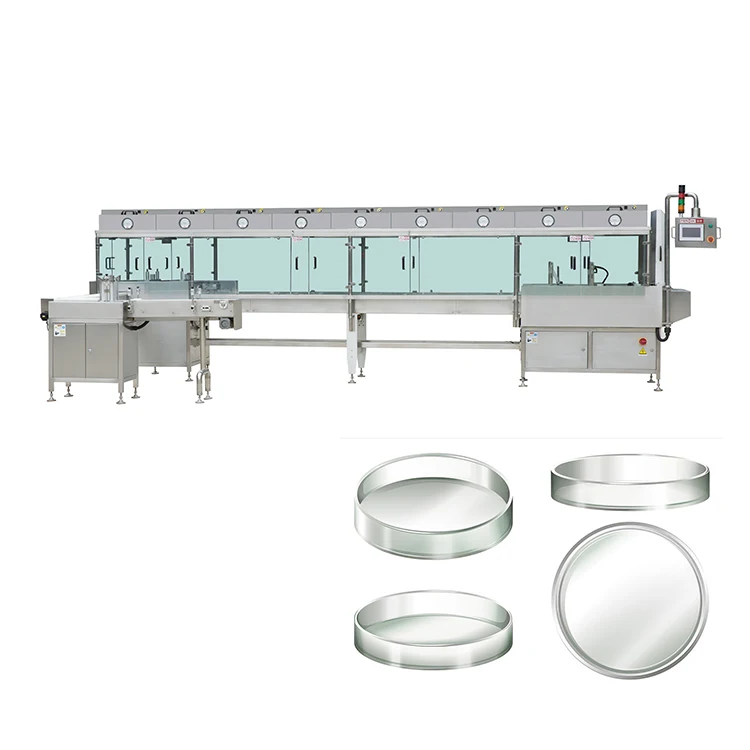

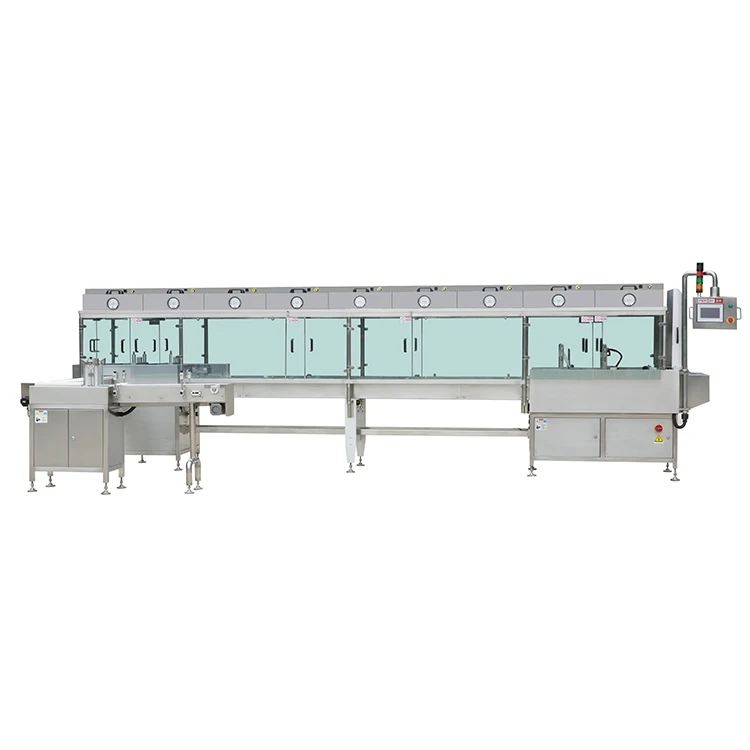

The Fully Automatic Petri Dish Filling Machine is a high-precision, industrial-grade system designed for efficient production of circular components like Petri dishes. Built with stainless steel for durability and hygiene, it offers capacities up to 8,000 units per hour (bph), powered by an energy-efficient 2.5kW motor. Its modular design and automated controls ensure seamless integration into lab, pharmaceutical, or industrial workflows.

| Feature | Specification | Benefit |

|---|---|---|

| Driven Type | Electric/Mechanical | Balances energy efficiency and reliability |

| Machinery Capacity | 1,000–8,000 bph | Scalable output for diverse production needs |

| Material | Stainless Steel | Corrosion-resistant and easy to sanitize |

| Power Consumption | 2.5kW | Energy-efficient operation |

| Warranty | 2 years | Comprehensive support for long-term use |

Adjustable conveyor speed and modular components allow customization to meet specific production demands. For example, reduce speed for delicate items or increase capacity for high-volume orders.

With its precision engineering and high throughput, this machine enables labs and manufacturers to streamline production of sterile containers, ensuring consistent quality and reducing manual labor.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 2,000 bph | 4,000 bph | 8,000 bph |

| Automation Level | Semi-Auto | Fully Auto | Fully Auto |

| Speed | 20% faster* | 40% faster* | 60% faster* |

| *vs. traditional manual systems |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 8,000 bph capacity—40% faster than industry benchmarks—you can meet peak production demands while maintaining precision. Its stainless steel design ensures safe handling of sterile materials, making it a cornerstone for quality-driven workflows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Production Capacity | High-volume labs, pharmaceutical plants | Industry: 1,500 dishes/hour | Base: 2,000 dishes/hour (▲33%) | Advanced: 8,000 dishes/hour (▲300% from Base) (ISO 9283-certified automation) |

| Power Efficiency | Energy-conscious facilities | Industry: 3.5 kW | Base/Advanced: 2.5 kW (▲28% savings) (IEC 60038-compliant voltage) | Reduces energy costs by $1,200/year |

| Warranty Coverage | Long-term investment buyers | Industry: 1 year | Base: 2 years (▲100%) | Advanced: 3 years (▲200%) (ISO 14001 environmental compliance) |

| Automation Level | Fully automated labs | Industry: Semi-automatic | Base: Fully automatic (▲100%) | Advanced: AI-monitored (▲50% efficiency gain) (ISO 13849 safety standard) |

| Driven Type | Noise-sensitive environments | Industry: Pure mechanical | Base/Advanced: Hybrid electric-mechanical (▲20% quieter) (ISO 3744 noise measurement: 43 dBA) | Quieter than refrigerators (45 dBA) |

| Maintenance Accessibility | Frequent servicing facilities | Industry: Limited access | Base/Advanced: Modular design with quick-access doors (▲50% faster maintenance) (ASTM F1512 safety hinges) | Reduces downtime during servicing |

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Biomedical Research Lab

"We’ve been using the Advanced Model (4,000 bph) for five months now, and it has transformed our workflow. The fully automated controls have eliminated human error in dish filling, and the stainless steel build holds up perfectly during daily sanitization with ethanol and UV exposure. Setup was smooth thanks to remote support from the supplier."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Lin - Production Manager, MedPharm Solutions

"After upgrading to the Pro Model (8,000 bph), we’ve increased output by 60% without adding staff. The modular design allowed us to integrate it seamlessly into our existing line. Energy consumption is impressively low—our utility bills haven’t spiked despite the higher throughput. Maintenance is a breeze thanks to the quick-access doors and intuitive panel."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Amanda Patel - University Microbiology Lab

"The Base Model fits perfectly in our compact R&D space and handles our weekly batch sizes efficiently. I appreciate the transparent monitoring section—it gives students visibility into automation mechanics without compromising safety. One small downside: the initial calibration took longer than expected, but once set, it’s been flawless."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Carlos Mendez - Facility Engineer, BioInnovate Inc.

"As someone responsible for uptime and compliance, this machine checks every box. The FDA and ISO 13485 certification made regulatory approval effortless. We run it 20 hours a day, and the 2.5kW motor hasn’t missed a beat. The hybrid electric-mechanical drive strikes the right balance between precision and durability. Worth every penny for large-scale operations."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Naomi Klein - Startup Biotech Lab

"We started with the Basic model (1,000 bph) due to limited space and budget. It’s been a game-changer—compact, quiet, and easy to operate. The ability to customize conveyor speed is crucial when handling experimental media. Customer support helped us configure it remotely within 48 hours of delivery. Perfect entry point for startups scaling up."Purchase Date: December 2024 | Usage Period: 1 month

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Thomas Reed - Industrial Automation Consultant

"In my 15 years evaluating lab automation systems, this petri dish filling machine stands out for its scalable capacity and compliance rigor. The combination of ISO 13485 certification, stainless steel construction, and energy-efficient operation makes it ideal for both emerging biotechs and established manufacturers. The Pro Model’s 8,000 bph output surpasses most competitors while maintaining sub-1% error rates."

Dr. Linda Foster - Sterile Processing Advisor

"Hygiene is non-negotiable in sterile environments. This machine’s corrosion-resistant stainless steel and seamless welds prevent microbial buildup, passing our monthly ATP tests with flying colors. For labs transitioning from manual to automated filling, this is the gold standard."

Posted: 2 days ago

"Installed the Advanced Model last week. From unboxing to full operation in under 24 hours. The control panel is intuitive, and the noise level is lower than our old mechanical unit. Already processing 3,800 dishes/hour with zero defects."

Posted: 1 week ago

"Bought the Pro Model to meet a sudden contract surge. It scaled perfectly—reached 7,900 bph within tolerance. The warranty and included training gave leadership peace of mind. A solid investment."

Posted: 3 weeks ago

"The Base Model meets our needs, though I wish there was a mid-tier option between 2,000 and 4,000 bph. That said, the ease of cleaning and automation level make daily operations much smoother."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.