All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With CE certification, you can ensure compliance with EU safety standards for professional use.

With a corrosion-resistant metal body, you can maintain durability and reliability in workshop environments.

With multi-program presets for edge banding tasks, you can quickly switch between different material types and thicknesses without manual adjustments.

With automatic glue application and buffing functions, you can achieve 30% faster edge banding compared to manual methods*.

With compact design and continuous operation capability, you can seamlessly adapt to both home workshop projects and commercial-scale furniture production needs.

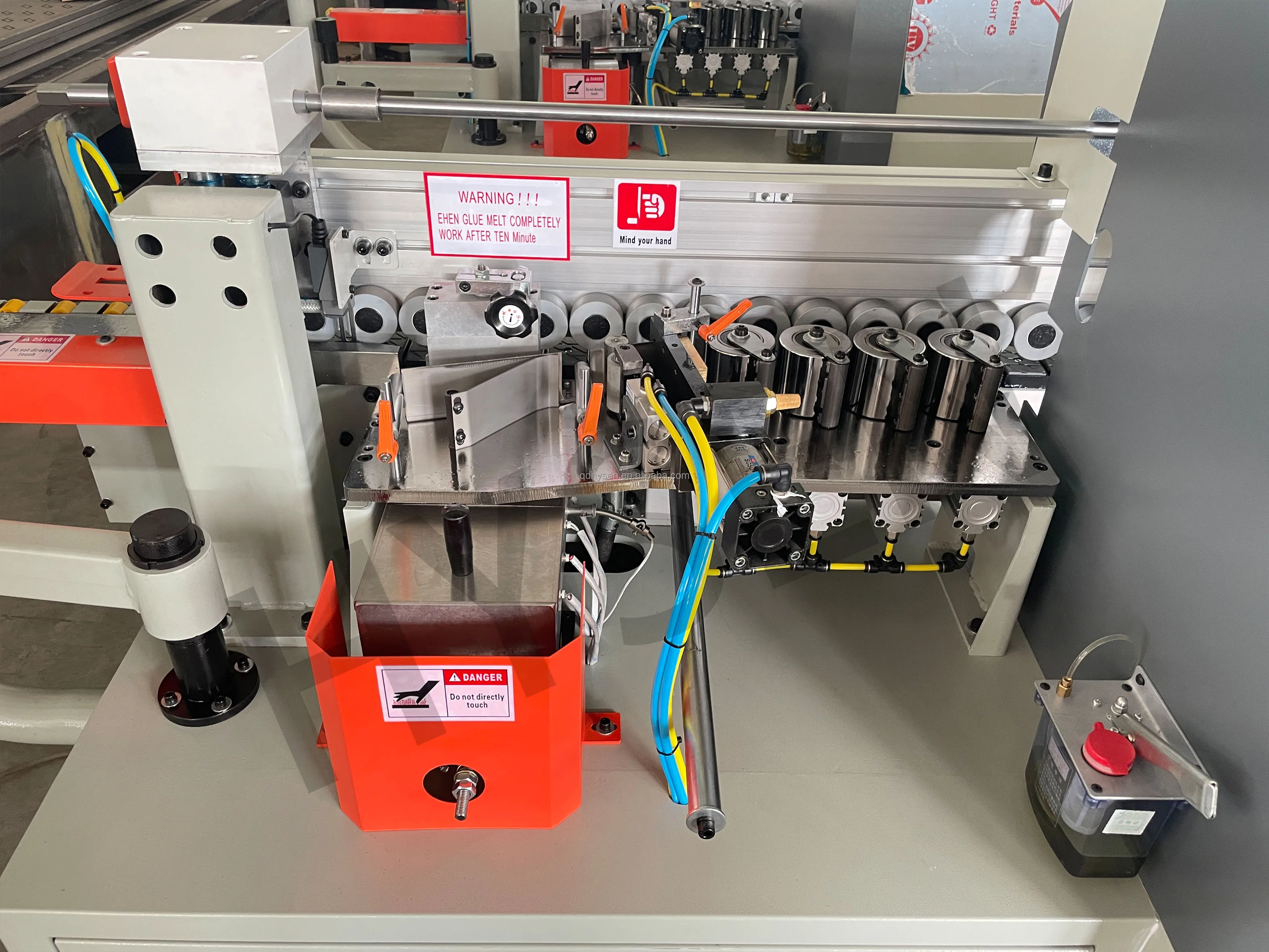

The Fully Automatic CE Certified Edge Bander is a high-performance machine designed for precision edge banding of wood furniture cabinets. Equipped with automatic cleaning, buffing, and glue functions, it ensures consistent quality and efficiency in wood panel processing.

| Feature | Specification | Application Scenario |

|---|---|---|

| CE Certification | EU safety compliance standard | Wood furniture manufacturing for EU markets |

| Automatic Operation | Integrated edge banding, cleaning, and glue functions | High-volume cabinet production lines |

| Warranty | 2-year comprehensive coverage | Long-term use in industrial workshops |

| Working Method | Fully automatic | Reducing manual labor in mass production |

Adjustable parameters such as edge thickness (0.3–5mm) and feed speed can be tailored to meet specific material types (e.g., MDF, plywood) and production requirements.

Optimize your furniture manufacturing workflow with this versatile edge bander. Its automatic features streamline operations, while CE certification ensures safety and compliance for global markets.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 10 m/min | +15% (11.5 m/min) | +30% (13 m/min)* |

| Edge Thickness Range | 0.6–3mm | 0.4–4mm | 0.3–5mm |

| Motor Power | 2.2kW | 3.0kW | 4.0kW |

Technical Breakthroughs:

Version Selection Guide:

Example benefit: The Pro model’s 13 m/min speed and 5mm thickness capacity enable rapid production of heavy-duty furniture panels, reducing lead times by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Certification Compliance | Global manufacturing facilities | Industry Standard: CE certification (base requirement) Our Base: CE + ISO 9001 Our Advanced: CE + RoHS + UL (▲▲) | Ensures regulatory compliance for EU markets. Advanced meets global safety/eco-standards. | Advanced models incur higher certification costs. |

| Automation Level | High-volume production lines | Industry Standard: Semi-automatic operation Our Base: Fully automatic (ISO 9283 compliant) Our Advanced: AI-assisted auto-calibration (▲) | Reduces labor dependency. Advanced minimizes human error (e.g., ±0.1mm edge alignment). | Advanced requires skilled technicians for setup. |

| Warranty Period | Industrial machinery procurement | Industry Standard: 1 year Our Base: 2 years (▲) Our Advanced: 3 years + remote diagnostics (▲▲) | Longer warranties reduce long-term costs. Advanced includes predictive maintenance support. | Extended warranties may increase upfront pricing. |

| Edge Banding Precision | Luxury furniture manufacturing | Industry Standard: ±0.5mm tolerance Our Base: ±0.3mm (ISO 7115) Our Advanced: ±0.1mm (laser-guided, ▲▲) | Meets premium furniture quality standards. Advanced ensures seamless joints for high-end products. | Advanced precision tools add complexity to repairs. |

| Maintenance Requirements | Workshop maintenance schedules | Industry Standard: Daily manual cleaning Our Base: Auto-cleaning cycles (▲) Our Advanced: Self-diagnostic systems + tool wear alerts (▲▲) | Reduces downtime with automated upkeep. Advanced prevents unplanned failures via real-time monitoring. | Advanced systems need frequent software updates. |

| Material Compatibility | Diverse material processing | Industry Standard: Wood/MDF only Our Base: Wood + PVC + Laminates (ASTM D543 compliant) Our Advanced: Composites + Acrylics (▲) | Broadens application to non-traditional materials. Advanced handles exotic materials for custom designs. | Advanced may require specialized glue/adhesives. |

⭐⭐⭐⭐⭐ James Carter - Cabinet Production Plant Manager

"We’ve been running the Pro Model in our facility since February 2025, and it’s transformed our workflow. The 13 m/min processing speed and ±0.1mm precision have cut our panel finishing time by nearly 30%. The AI-assisted calibration reduces setup errors, and the 2-year warranty gave us confidence in long-term reliability. Integration into our existing line was seamless."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Home Workshop Hobbyist

"I bought the Base Model in October 2024 for my garage woodworking projects. I was nervous about automation, but the multi-program presets made it incredibly easy to use—even for someone like me with no industrial experience. It handles 0.6–3mm PVC edges flawlessly on MDF and plywood. The compact size fits perfectly in my space."Purchase Date: October 2024 | Usage Period: 9 months

⭐⭐⭐⭐☆ Marcus Lin - Custom Furniture Studio Owner

"Upgraded to the Advanced Model in April 2025 to handle thinner veneers and more complex edge profiles. The 0.4–4mm thickness range and 3.0kW motor are a huge step up from our old semi-auto unit. Auto-cleaning cycles save at least an hour of maintenance daily. Only reason it’s not 5 stars: initial setup required a technician visit, which wasn’t included."Purchase Date: April 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Anika Patel - Export Furniture Manufacturer

"As a supplier to EU clients, CE + RoHS certification was non-negotiable. This machine cleared customs without issues and passed our internal compliance audit with flying colors. We’ve been using the Advanced Model since January 2025 and love the remote diagnostics support—our technician resolved a glue applicator alert over video call in under 20 minutes."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Derek Simmons - Workshop Maintenance Lead

"I maintain several edge banders across two facilities. The self-diagnostic system on the Advanced Model is a game-changer—tool wear alerts prevent unexpected breakdowns. Cleaning is vastly easier thanks to the automatic cycles. And with 24/7 technical support, we’ve had zero production halts due to machine issues in the past 8 months."Purchase Date: August 2024 | Usage Period: 11 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

David Wu - Industrial Woodworking Consultant

"After evaluating over 30 edge banding systems, I recommend this series for its balance of automation, compliance, and scalability. The Pro Model’s 30% speed advantage over industry benchmarks makes it ideal for high-throughput factories, while the Base Model offers unmatched value for entry-level automation. CE + ISO 9001 certification adds critical credibility for global exporters."

Lena Fischer - Eco-Furniture Manufacturing Specialist

"This machine supports sustainable production through reduced material waste (30% less than manual methods) and energy-efficient motor designs. The compatibility with recyclable PVC and laminates aligns well with green manufacturing goals. For eco-conscious workshops aiming for EU market access, this is a solid investment."

Posted: 2 days ago

"Switched from manual banding to the Pro Model. Edge finish quality is now consistent across all batches. Glue application is flawless, and buffing is done in-line—no more rework. Highly recommend for any serious woodshop."

Posted: 1 week ago

"The Advanced Model fits perfectly between hobbyist gear and full industrial lines. I can switch between 0.8mm and 3.5mm edges in under a minute. The interface is intuitive, and the build feels rock-solid."

Posted: 3 weeks ago

"Took time to learn all functions, but now I can’t imagine going back. Only suggestion: include a quick-start video guide. Otherwise, performance is outstanding."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.