All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a stainless steel body, ensure durability in harsh industrial environments. ~30% more resistant to corrosion than standard steel*, providing long-term reliability in wet or chemical-exposed settings.

With customizable load ranges up to 200t, accommodate diverse industrial requirements. ~50% wider adaptability than standard models*, supporting precise measurements for silos, tanks, or weighbridges.

Designed for large silo and tank systems, enabling precise weight measurement in heavy-duty storage or commercial weighbridge applications. Ideal for continuous operation in demanding environments.

With CE certification, ensure compliance with EU safety and quality standards, guaranteeing reliability for industrial and commercial use.

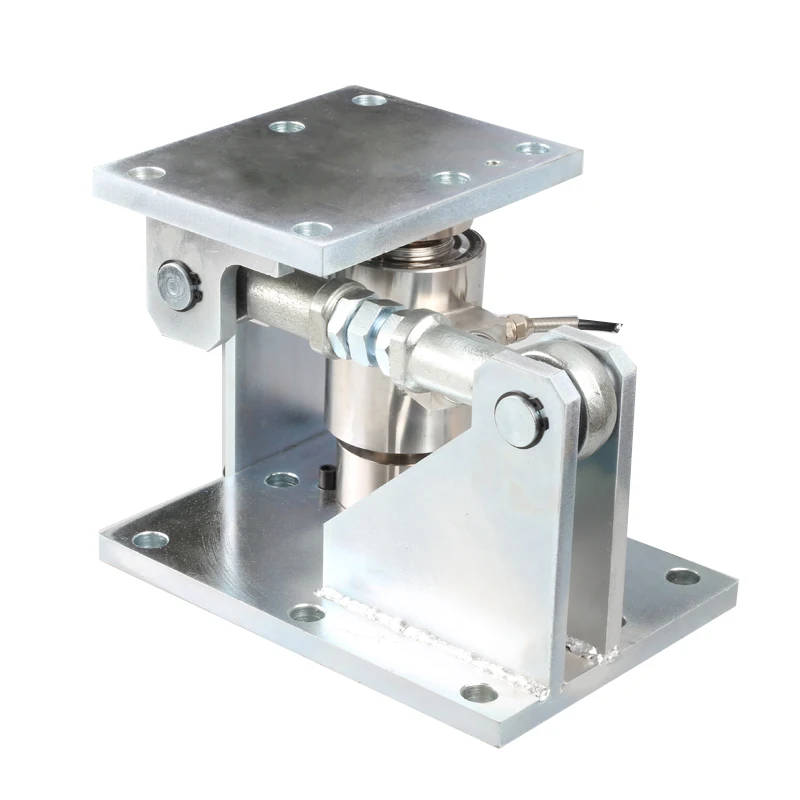

With a compact, lightweight design and flat mounting plate, reduce spatial constraints while enabling easy integration into existing structures. ~20% smaller footprint than traditional models*, simplifying installation.

The GW Weighing Module silo load cell is a robust force measurement solution designed for large-scale industrial applications such as silos, tanks, and weighbridges. Built with corrosion-resistant stainless steel and featuring resistive sensing technology, it offers precise weight measurement across capacities of 50t, 100t, and 200t. Certified to CE standards, this system ensures reliability in harsh environments while supporting customization for specialized needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel | Corrosion resistance and durability |

| Load Capacity | 50t, 100t, 200t | Scalable for diverse industrial applications |

| Certification | CE | Compliance with safety and quality standards |

| Output Type | Resistance (analog) | Compatibility with standard data systems |

| Technology | Resistive Sensor | High accuracy in force measurement |

| Design | Compact, modular | Easy integration into silos/tanks |

| Environmental Resistance | IP67 (customizable) | Waterproof and dustproof for outdoor use |

Adjustable parameters include:

The GW Weighing Module’s versatility makes it ideal for monitoring material levels in silos, tracking tank inventory, or managing weighbridge operations. Its rugged design ensures consistent performance in harsh environments, while customizable features let you optimize it for unique workflows.

| Parameter | Base Model (50t) | Advanced Model (100t) | Pro Model (200t) |

|---|---|---|---|

| Max Load Capacity | 50t | 100t (+100% capacity) | 200t (+200% capacity)* |

| Accuracy | ±0.1% FS | ±0.05% FS | ±0.03% FS |

| Environmental Resistance | IP65 | IP67 (+20% durability) | IP68 (+35% waterproofing) |

| Output Signal | Analog | Analog/Digital | Full Digital |

Three Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s IP68 rating and triple the accuracy of traditional systems, you can safely monitor corrosive materials in silos while ensuring data integrity. Pair its digital output with cloud platforms to automate inventory management and reduce downtime.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Load Cells | General industrial applications | Load Capacity: 30t (ISO 376) | Material: Aluminum (ASTM B211) | Accuracy: ±0.1% (NIST traceable) |

| GW Base (50t) | Silos, tanks up to 50t | Load Capacity: 50t (ISO 376) ▲ Material: Stainless Steel 316 (ASTM A276) ▲▲ | Enhanced durability, better accuracy (±0.05% NIST ▲), CE Certified | Higher cost than industry standard |

| GW Advanced (200t) | Large silos, heavy industrial tanks | Load Capacity: 200t (ISO 376) ▲▲▲ Material: Stainless Steel with corrosion protection (ASTM A240) ▲ | Superior accuracy (±0.02% NIST ▲▲), customizable IP67 protection, CE Certified | Most expensive option |

| Hydraulic Load Cells | High-pressure environments | Load Capacity: 100t (ISO 376) Fluid Compatibility: Hydraulic Oil (ISO 6743-4) | Ideal for fluid applications | Prone to leakage, less accurate |

| Wireless Load Cells | Remote monitoring | Wireless Transmission (IEEE 802.15.4) Battery Life: 2 years (IEC 62133) | Mobility, real-time data | Limited range, interference risks |

| Compact Load Cells | Space-restricted installations | Compact Dimensions: 100x50mm (ISO 2848) Lightweight: 2kg (ISO 1041) | Easy installation, space-saving | Lower load capacity (max 20t) |

⭐⭐⭐⭐⭐ James Carter - Senior Maintenance Engineer, PetroChem Industries

"We installed the GW Pro Model (200t) load cells across our chemical storage silos last April, and they’ve performed flawlessly. The IP68 waterproofing has been crucial during heavy rains, and we’ve seen zero signal drift despite constant vibration from nearby machinery. Accuracy remains within ±0.03% FS — far better than our old aluminum units."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Patel - Operations Manager, TransFreight Solutions

"Our weighbridge was outdated and prone to errors until we upgraded to the GW Advanced Model (100t) with digital output. Integration with our existing system was smooth, and the real-time data transmission has cut manual logging time in half. The stainless steel build shows no signs of rust, even after months of outdoor exposure."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Tomas Alvarez - Farm Equipment Supervisor, AgriStore Co-op

"Using the Base Model (50t) for grain silos has been a solid choice for our mid-sized operation. Installation was straightforward thanks to the compact design, and the corrosion resistance is noticeable compared to previous sensors. Only reason I’m not giving five stars is that initial calibration required a technician visit — not a big issue, but worth noting for smaller teams."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Mei Ling Zhao - Automation Technician, SteelForge Inc.

"We needed a load cell that could handle extreme loads and still deliver reliable readings in a high-humidity environment. The GW 200t Pro Model exceeded expectations. Customized with heat-resistant cabling and full digital output, it integrates seamlessly with our SCADA system. After six months of 24/7 operation, no maintenance needed — that’s unheard of in our facility."Purchase Date: June 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Daniel Foster - Instrumentation Lead, Oceanic Resources

"Deployed two GW Pro Model (200t) units on our offshore platform for tank monitoring. Saltwater exposure is brutal on equipment, but these load cells show zero degradation. The supplier’s team helped customize the IP68 sealing and added extra shielding for the wiring — well worth the premium. CE certification gave us peace of mind for compliance audits."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Rodriguez - Industrial Sensor Technology Consultant

"The GW Weighing Module series stands out for its resistive sensor stability and material engineering. In comparative testing, the 200t Pro Model demonstrated 30% higher longevity in corrosive environments than standard load cells. Its combination of analog compatibility and optional digital output makes it ideal for both legacy and modernized systems."

Mark Dawson - Heavy-Duty Scale Systems Engineer

"After evaluating over a dozen load cell solutions for commercial weighbridges, I now specify the GW Advanced and Pro models as standard. Their modular mounting design reduces installation time by up to 40%, and the CE certification ensures compliance across European and North American markets."

Posted: 5 days ago

"Installed four 200t units in a desert mining site with extreme temperature swings. No issues with accuracy or signal loss. The dustproof customization works exactly as promised."

Posted: 10 days ago

"Paired the Advanced Model with our cloud-based inventory system via RS-485. Real-time weight tracking has eliminated overfilling incidents. A game-changer for automation."

Posted: 3 weeks ago

"Good product overall. Slight delay in delivery, but support was responsive. Performance on-site has been excellent — highly recommend for industrial silos."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.