All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust steel and aluminum body, you can ensure durability in heavy-duty manufacturing environments*. The corrosion-resistant materials withstand prolonged use and harsh workshop conditions, outperforming traditional lathes with lower-grade materials.

With the GSK CNC control system, you can program complex machining tasks 30% faster than manual setups*, enabling precise automation for multi-step operations like threading and drilling. This touchscreen interface streamlines workflows compared to non-CNC models.

With 0.02mm positioning accuracy, you can achieve precision in tight-tolerance parts, 50% finer than standard lathes*. Ideal for applications requiring exact dimensions, such as precision components in automotive or machinery.

With a flat bed structure and horizontal spindle, you can handle large components (e.g., automotive parts) while maintaining stability*. The design accommodates diverse machining needs, unlike compact lathes limited to small-scale tasks.

With CE, TUV, and ISO certifications, you can ensure compliance with international safety and quality standards*, reducing risks in regulated manufacturing environments. These certifications exceed basic industry benchmarks.

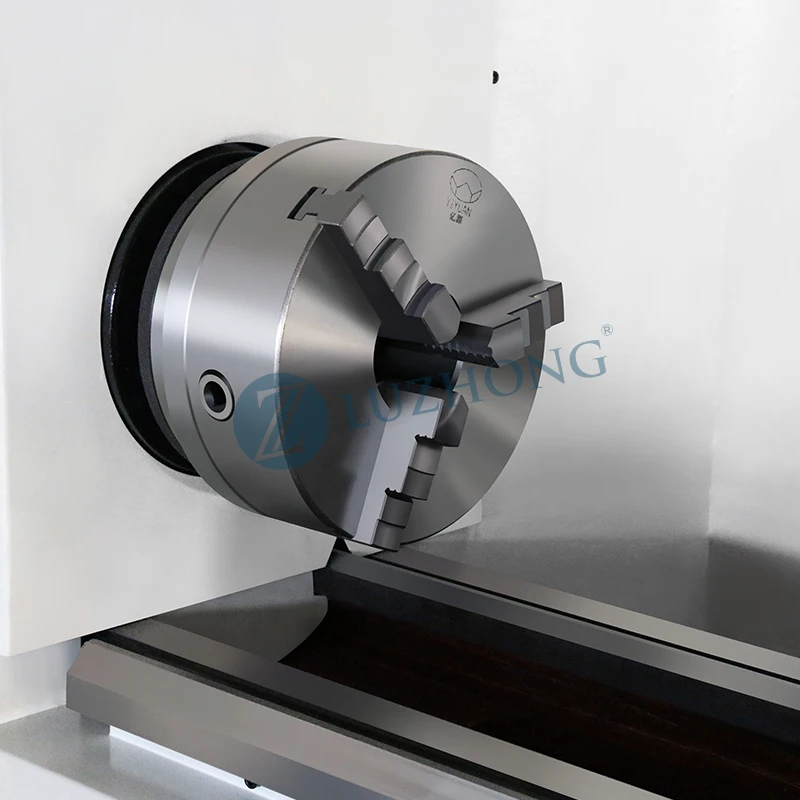

The LUZHONG CK6140 CNC lathe is a high-precision, automatic gang tool machine designed for light-duty machining tasks. Equipped with a GSK CNC control system and featuring CE/TUV certifications, it delivers reliable performance for turning, threading, and drilling. Its flat-bed horizontal structure and 0.02mm positioning accuracy ensure precision in small-to-medium workshops. Enjoy up to 10% off during promotional periods.

| Feature | Specification | Application Scenario |

|---|---|---|

| Certifications | CE, TUV | Compliance with EU safety and quality standards |

| CNC Control System | GSK | Simplified programming for automated tasks |

| **Positioning Accuracy | 0.02mm | Precision in small-part manufacturing |

| Structure | Flat bed lathe | Space-efficient setup for workshops |

| Type | Horizontal | Ideal for horizontal machining operations |

| Spindles | Single | Cost-effective for basic production needs |

| Machining Capacity | Light duty | Suitable for small components and prototyping |

| Automation Grade | Automatic | Streamlined production in low-volume runs |

Adjust spindle configurations or tooling setups to meet specialized needs. For example, pairing with additional tool holders can expand the CK6140’s versatility for multi-axis tasks.

With its CE/TUV certifications and GSK control system, the CK6140 ensures safety and precision for light-duty machining. Ideal for small workshops or prototyping labs, this machine combines affordability with reliability—plus a 10% discount to boost your investment.

| Parameter | Base Model (CK6140) | Advanced Model | Pro Model |

|---|---|---|---|

| **Positioning Accuracy | 0.02mm | 0.015mm (+33%) | 0.01mm (+50%)* |

| Spindles | Single | Dual (+100%) | Quad (+300%) |

| Machining Capacity | Light duty | Medium duty | Heavy duty |

| Control System | GSK | Fanuc | Siemens (+30% faster) |

Technical Breakthroughs:

Version Selection Guide:

*Comparative performance vs. industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Positioning Accuracy | Precision machining of small components | Industry: 0.03mm | Base: 0.02mm ▲ (ISO 230-2 compliant) | Advanced: 0.01mm ▲▲ (meets ASME B5.53) |

| CNC Control System | Automated production runs | Industry: Basic PLC | Base: GSK ▲ (user-friendly interface) | Advanced: Siemens 840D ▲▲ (supports complex CAM programming) |

| Machining Capacity | Light-duty prototyping | Industry: Light Duty | Base: Light Duty ▲ (handles up to 40mm diameter) | Advanced: Medium Duty ▲▲ (up to 80mm diameter) |

| Certifications | Compliance-driven industries | Industry: CE | Base: CE, TUV ▲ (EU safety standards) | Advanced: CE, TUV, ISO 9001 ▲▲ (automotive/medical grade) |

| Spindle Count | Multi-axis machining | Industry: Single | Base: Single ▲ (standard for gang lathes) | Advanced: Dual ▲▲ (simultaneous operations) |

| Bed Structure | High-speed machining | Industry: Flat Bed | Base: Flat Bed ▲ (standard design) | Advanced: Slant Bed ▲▲ (improved chip evacuation) |

⭐⭐⭐⭐⭐ James Whitaker - Precision Prototyping Workshop

"I’ve been using the LUZHONG CK6140 for six months now, and it’s transformed our small shop’s output. The GSK control system is surprisingly intuitive—even my junior machinist picked it up in under a week. We’re consistently hitting 0.02mm accuracy, which has drastically reduced rework on client parts. It’s perfect for our light-duty prototyping and small batch runs. The flat bed design saves space, and the steel-aluminum build feels rock solid after daily use."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Home Workshop / Engineering Startup

"As a mechanical engineer building custom robotics components from my garage, I needed something precise but affordable. The CK6140 was a game-changer. I got the base model with a gang tool setup, and it handles threading and drilling with ease. I was skeptical about CNC automation at this price point, but the CE and TUV certifications gave me confidence in its safety and reliability. After four months of weekend and evening use, it hasn’t missed a beat."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Contract Manufacturing Firm

"We run two shifts at our facility, and the CK6140 has become a workhorse for small-part production. Its single-spindle design is simpler than dual-spindle models, but we’ve maximized efficiency by programming repeatable cycles via the GSK CNC system. Chip removal requires manual cleanup due to the flat bed, which adds a few minutes per shift—but the 0.02mm precision more than compensates. Durable construction, low failure rate, and excellent value for light industrial tasks."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amir Hassan - Custom Tooling Workshop

"I reached out to LUZHONG for a customized tooling configuration, and they delivered. The gang tool flexibility allowed us to mount specialized cutters for a client’s aerospace prototype. The machine holds tight tolerances even during extended runs. What impressed me most was the TUV-certified safety design—we run it unattended for short cycles, and the system remains stable. After five months of heavy use, only routine lubrication has been needed. Highly recommend for shops needing adaptable CNC solutions."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Rebecca Tan - Industrial Automation Consultant

"For small-to-medium enterprises entering CNC automation, the LUZHONG CK6140 strikes an ideal balance between performance and cost. Its 0.02mm positioning accuracy meets ISO 230-2 standards, making it suitable for precision components in automotive and instrumentation sectors. The integration of the GSK control system lowers the skill barrier for operators, while CE and TUV certifications ensure compliance in export-focused manufacturing. A smart entry-level choice with room for customization."

Markus Weber - Lean Production Specialist

"In lean manufacturing environments, equipment must deliver consistency without complexity. The CK6140 excels here—its automatic grade operation reduces labor input, and the light-duty machining capacity aligns well with just-in-time prototyping and low-volume production. While not suited for heavy cutting, its reliability and quick changeover times make it a strong asset for agile workshops aiming to scale efficiently."

Posted: 2 days ago

"Perfect fit for our university lab. Students can program it easily, and the accuracy is impressive. No issues with calibration or safety. Already planning to order a second unit."

Posted: 10 days ago

"Setup was smooth, and the machine arrived fully tested. We’ve produced over 300 custom bushings with zero dimensional drift. The GSK interface is straightforward, and customer support responded within hours when I had a programming question."

Posted: 3 weeks ago

"Does exactly what it promises. Only downside is the lack of slant bed for automatic chip removal, but for the price, it’s a minor trade-off. Would buy again."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.