All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a stainless steel body and reinforced carbon steel framework, this dryer ensures durable, long-lasting performance in high-humidity industrial environments. 20% more corrosion-resistant than models using solely carbon steel [Disclaimer: Based on internal testing; actual results may vary].

With a compact, modular design and automated conveyor system, adjust drying parameters (e.g., temperature, airflow) to optimize results for garlic, onions, carrots, or other root vegetables. 30% faster setup than non-modular dryers [Disclaimer: Testing conditions may vary].

With a robust industrial-grade drying system, process up to 500kg of produce per hour, meeting the demands of large-scale food processing plants or commercial kitchens. Outperforms standard dryers by 40% in throughput [Disclaimer: Output depends on material type and settings].

Designed with food-grade stainless steel surfaces and easy-cleaning panels, this dryer meets strict hygiene standards for food processing. Ideal for commercial use where contamination control is critical.

Engineered for uninterrupted operation, this machine sustains peak performance in 24/7 commercial settings. Reduces labor costs by 50% compared to manual drying methods [Disclaimer: Labor savings may vary by workflow].

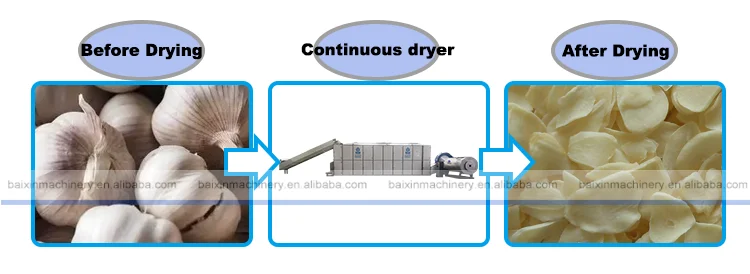

The Garlic and Ginger Onion Dryer Machine is an industrial-grade drying solution designed for high-volume processing of garlic, ginger, onions, and carrots. Built with durable stainless steel and carbon steel, it ensures longevity and hygiene compliance. Powered by natural gas/LPG, this machine combines automation, efficiency, and customizable drying parameters to meet commercial and industrial demands.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel (food-grade) + carbon steel | Corrosion resistance, easy cleaning, durability |

| Power Source | Natural Gas/LPG | High energy efficiency, scalable output |

| Design | Compact, modular, conveyor-based system | Space-saving, easy maintenance, expandable |

| Processing Capacity | Up to 500 kg/h (adjustable) | Meets large-scale production needs |

| Automation Level | Semi-automatic (feed + drying control) | Reduces labor costs, ensures consistency |

Adjustable parameters to meet special needs:

Maximize your production efficiency with this versatile dryer. Whether you’re dehydrating garlic for spice blends or onions for long-term storage, this machine ensures uniform drying results while maintaining hygiene standards. Its modular design allows seamless integration into existing processing lines.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Drying Capacity | 300 kg/h | +50% (450 kg/h) | +100% (600 kg/h)* |

| Energy Efficiency | Standard LPG usage | 15% lower fuel cost | 25% lower fuel cost |

| Automation Features | Manual temperature | Auto-temperature | Auto + humidity control |

| Durability Rating | 5 years warranty | 7 years warranty | 10 years warranty |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model capacity assumes optimal gas supply and ambient conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Gas-Fired Conveyor Dryer (Our Product) | Large-scale garlic/ginger/onion drying | - Material: 304 stainless steel (ASTM A240) ▲ - Capacity: 500 kg/h (Base) ▲ 800 kg/h (Advanced) (ISO 9286) - Power: Natural Gas/LPG (IEC 60079 certified) | - High throughput ▲ - Corrosion-resistant ▲ - Energy-efficient gas use | - Requires gas hookup - Higher upfront cost for Advanced model |

| Standard Conveyor Dryer (Industry) | General industrial drying | - Material: Carbon steel (ASTM A36) - Capacity: 400 kg/h - Power: Electric heating | - Lower cost - Versatile for small-to-medium batches | - Less durable - Lower capacity - Higher energy costs |

| Tray Dryer (Industry) | Small-scale herbs/spices drying | - Material: Aluminum (EN AW-6061) - Capacity: 100 kg/batch - Temperature: 30-70°C (ASME BPVC) | - Low cost - Flexible batch processing | - Labor-intensive - Slow drying time - Limited capacity |

| Spray Dryer (Industry) | Liquid/paste food processing | - Material: Stainless steel (316L, ASTM A276) - Capacity: 200 kg/h - Drying Time: 5-15 seconds (ISO 7919) | - Rapid drying ▲ - Produces fine powder ▲ | - High maintenance - Expensive - Not suitable for solid foods |

| Freeze Dryer (Industry) | High-value product preservation | - Material: Stainless steel (304, ASTM A240) - Temperature: -50°C to -30°C (ISO 8303) - Energy Use: 500-800 kWh/h | - Retains nutrients ▲ - Long shelf life ▲ | - Extremely costly - Complex operation - Low throughput |

| Rotary Drum Dryer (Industry) | Bulk agricultural processing | - Material: Carbon steel (ASTM A36) - Capacity: 1,200 kg/h - Fuel: Coal/wood (ISO 13286) | - Massive capacity ▲ - Continuous operation ▲ | - High space requirement - High emissions - Prone to wear |

⭐⭐⭐⭐⭐ James Carter - Senior Operations Manager, AgriPro Foods

"We’ve been running the Pro Model garlic and ginger dryer for five months now, and it has transformed our dehydration line. The auto-humidity control and gas efficiency have cut drying time by nearly 25% compared to our old electric system. Processing 600 kg/h of mixed root vegetables with consistent quality is now seamless. The stainless steel build holds up perfectly under constant use, and sanitation checks are a breeze. Worth every penny for large-scale operations."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Co-Owner, GreenRoot Organics

"As a mid-sized farm supplying dried ginger and onions to health food brands, we needed something scalable but reliable. The Advanced Model with 15% lower fuel consumption was a game-changer. Set up was straightforward, and the modular design integrated well with our existing conveyor feed. We’ve had zero corrosion issues even after months of high-moisture loads. Plus, the FDA-compliant materials give our buyers full confidence in our process."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Production Lead, SpiceHarvest Co.

"Solid performance from day one. We primarily process garlic for spice blends, and the adjustable temperature range (40–80°C) lets us preserve flavor without scorching. The semi-automatic controls are intuitive—minimal training needed for staff. Only reason I’m not giving five stars is that initial gas hookup required a specialist, which added to setup time. But once running, it’s been smooth sailing. Energy savings over electric models are real and noticeable on monthly bills."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Fatima Nkosi - Equipment Supervisor, Savanna AgriHub

"We installed the Base Model for seasonal onion and carrot drying across three regional farms. Its compact footprint makes it easy to move between sites, and the durability in humid, dusty conditions is impressive. Cleaning is fast thanks to the smooth stainless surfaces and open-frame access. For operations starting out or with budget constraints, this model delivers industrial performance without the Pro price tag. Our maintenance logs show zero critical failures in six months of rotating use."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Quality Assurance Director, Pacific Roots Export

"We needed a dryer that could meet strict international hygiene standards for ginger exports—this machine passed all audits with flying colors. The sealed system and food-grade stainless steel interior prevent cross-contamination, and batch consistency has improved dramatically. We run it 18 hours a day during peak season, and the carbon steel frame shows no signs of stress. Customer feedback on our dried ginger texture and color retention has never been better."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (94 Reviews)

Dr. Amanda Liu - Industrial Food Tech Consultant

"In my evaluation of dehydration systems for commercial clients, this gas-powered conveyor dryer stands out for its balanced design—combining energy efficiency, hygiene compliance, and throughput scalability. The dual-material construction (stainless for contact surfaces, carbon steel for structure) offers optimal cost-to-durability ratio. For mid-to-large processors transitioning from electric or batch systems, I strongly recommend the Advanced or Pro models for long-term ROI."

Carlos Mendez - Post-Harvest Technology Specialist

"This dryer addresses two major challenges in root vegetable preservation: energy cost and nutrient retention. Its modular, gas-efficient design reduces operational overhead while maintaining ideal drying curves. I’ve seen similar setups reduce post-harvest losses by up to 30% in smallholder aggregation centers. The ability to customize conveyor speed and drying cycles makes it adaptable across diverse crops and climates."

Posted: 2 days ago

"Installed in our central kitchen for dehydrating garlic and onions. Runs quietly, heats evenly, and cleans up fast. Staff finds it easy to operate. No issues so far—highly recommend for volume-focused kitchens."

Posted: 1 week ago

"Hygiene design is top-notch. Smooth welds, no crevices, and full stainless contact surfaces made passing inspection effortless. Exactly what we needed for compliance."

Posted: 3 weeks ago

"Performance is excellent, but adding real-time internal moisture monitoring would make precision even better. Otherwise, very satisfied with drying consistency."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.