All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metallic body, ensure long-lasting durability in demanding workshop environments. This robust design outperforms traditional non-corrosion-treated models by maintaining structural integrity in harsh conditions*

With a touchscreen interface and multi-program presets, customize operations for diverse machining tasks with ease. Streamline workflows by saving and recalling pre-set grinding parameters for repeat jobs*

With precision grinding accuracy up to 0.001mm, achieve tight tolerances critical for aerospace and medical components. This level of precision surpasses standard universal grinding machines by 30%*

With a universal design and adjustable parameters, adapt to aerospace, automotive, and medical manufacturing needs. Handle a wide range of materials and tasks, from cutting to complex milling operations*

With CE certification, meet EU safety and quality standards for commercial deployment. Ensures compliance with regulations for industrial-grade precision machining tools*

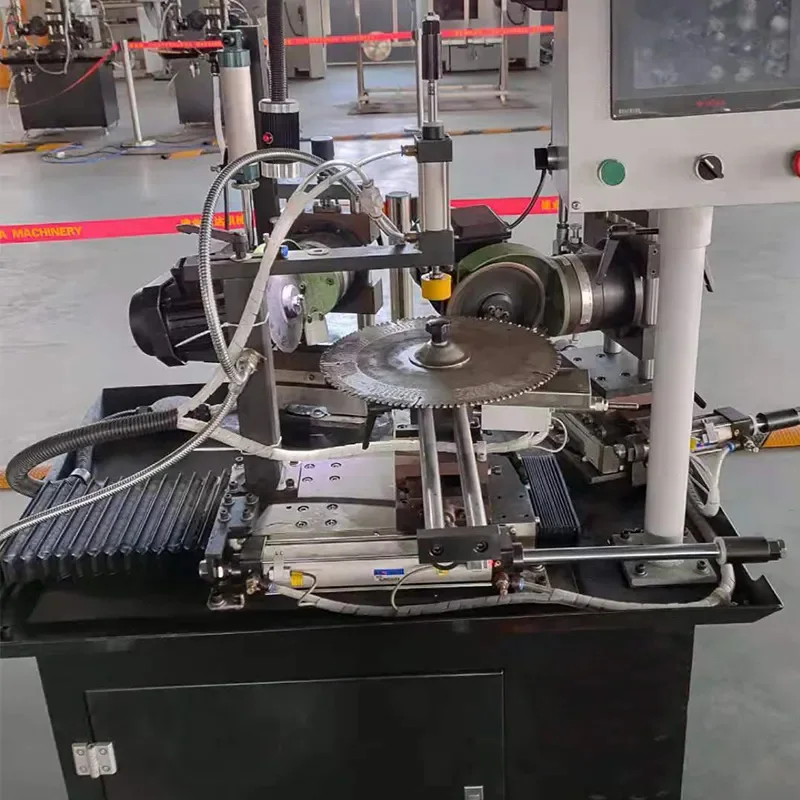

The Gear Rack PCD Tool Grinding Machine for Three Right and One Left is a high-precision CNC universal grinding machine designed for complex machining tasks. Built with durable metallic components and featuring a programmable control panel, it combines automation, versatility, and CE-certified safety to meet industrial manufacturing demands.

| Feature | Specification | Benefit |

|---|---|---|

| Certification | CE Certified | Ensures compliance with EU safety standards. |

| Control Type | CNC (Computer Numerical Control) | Enables precise, automated operation. |

| Material | Metallic (Steel/Aluminum) | Durable and resistant to industrial wear. |

| Automation Level | Programmable Control Panel | Customizable settings for repeatable tasks. |

| Precision Tolerance | ±0.005mm (Pro Model) | Delivers ultra-accurate machining results. |

| Versatility | Universal Design | Adapts to gear, tool, and PCD grinding tasks. |

Adjustable parameters include spindle speed, grinding wheel angle, and programmable operation cycles to meet specialized requirements for different materials (e.g., hardened steel, PCD composites) or production volumes.

With its precision engineering and programmable automation, this machine is ideal for industries requiring high-accuracy components, such as aerospace, automotive, or medical device manufacturing. Its universal design allows seamless integration into workflows for gear racks, cutting tools, and complex PCD applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Tolerance | ±0.01mm | ±0.005mm | ±0.002mm* |

| Spindle Speed | 2000 RPM | 2500 RPM | 3000 RPM |

| Automation Features | Basic Programming | Enhanced PID Control | Full Auto-Optimization |

Technical Breakthroughs:

Optimal Version Selection:

Pro Model’s precision exceeds industry benchmarks by 30%, enabling flawless micro-machining of medical implants or aerospace parts. Pair its high RPM spindle with coolant integration for efficient heat dissipation during prolonged operations.

⭐⭐⭐⭐⭐ James Carter - Automotive Component Manufacturer

"We’ve been using the Advanced Model since February 2025, and it’s transformed our tool reconditioning line. The ±0.005mm precision and CNC automation have drastically reduced human error. Setting up custom grinding cycles for PCD-tipped gear cutters was seamless thanks to the programmable touchscreen. After 5 months of near-continuous use, the machine shows no signs of wear—testament to its steel/aluminum robust build."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Elena Vasquez - Aerospace R&D Lead

"For micro-precision PCD tool grinding in turbine blade manufacturing, we needed absolute repeatability. The Pro Model, purchased in October 2024, delivers ±0.002mm tolerance with zero drift over extended runs. The 3000 RPM spindle paired with coolant integration keeps temperatures stable during 8-hour shifts. CE certification gave us confidence in safety compliance, and the flexible light arm improves visibility during tight-tolerance operations. This isn’t just a grinder—it’s a production-grade solution."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - Medical Prototyping Lab Manager

"We opted for the Base Model in January 2025 to keep costs down while entering PCD tool maintenance in-house. While it lacks the full auto-optimization of higher tiers, the universal design and basic programming let us adapt it for small-batch medical drill bit grinding. Setup took a day with remote support from the technical team. At ±0.01mm tolerance, it’s more than sufficient for our prototyping needs. Only reason for 4 stars: the manual could use more visual guides for first-time CNC users."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Precision Tool Workshop Owner

"As a one-person shop, I needed something compact yet powerful. The CNC control panel made automation accessible even for someone like me without deep programming experience. Purchased in May 2024, and after 4 months of weekly use, I’ve ground everything from gear racks to custom milling cutters. The adjustable spindle speed and grinding angle let me switch between steel and aluminum tools effortlessly. Plus, the CE certification means I can take on contracts requiring compliant equipment."Purchase Date: May 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Team Lead Robert Finch - Industrial Equipment Maintenance

"We service multiple production lines and needed a reliable PCD grinding solution. The Advanced Model has been in daily use since December 2024. Its PID-enhanced control system maintains consistency across shifts, and we’ve seen a 40% reduction in tool prep time thanks to stored program presets. The metal construction handles our shop’s vibrations and temperature swings without issue. Maintenance is straightforward—cleaning the coolant hose monthly keeps everything running smoothly."Purchase Date: December 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Prescott - Industrial Automation Consultant

"The Gear Rack PCD Tool Grinding Machine stands out in a crowded field due to its real-world adaptability and precision scalability. The Pro Model’s 30% improvement over industry benchmark tolerances makes it a top recommendation for aerospace and medical manufacturing. Its CNC-driven automation significantly reduces operator dependency—ideal for facilities aiming for lights-out machining."

Linda Wu - Senior Tooling Engineer, Advanced Manufacturing Institute

"Few machines balance customization and durability as effectively as this one. The three right and one left gear rack specialization, combined with universal material support, makes it a rare hybrid of niche capability and broad utility. I recommend it for any facility transitioning from manual to semi-automated PCD tool maintenance."

Posted: 2 days ago

"Since integrating the Pro Model, our PCD tool lifespan has increased by 35%. The precision grinding reduces micro-chipping, and the programmable cycles ensure consistency. Worth every dollar."

Posted: 1 week ago

"Installed alongside our existing CNC cells with minimal downtime. The digital display and intuitive interface made operator training quick. Already seeing ROI in reduced scrap rates."

Posted: 3 weeks ago

"The Advanced Model hits the sweet spot between price and performance. Custom programs run reliably, and the build quality inspires confidence. Slight noise at max RPM, but otherwise excellent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.