All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, you can ensure long-term reliability in harsh industrial environments, outperforming plastic-bodied alternatives*.

With a Gigabit Ethernet (GigE) interface, you can transmit high-resolution data 30% faster than USB 3.0-based cameras*, enabling real-time inspection in fast-paced assembly lines.

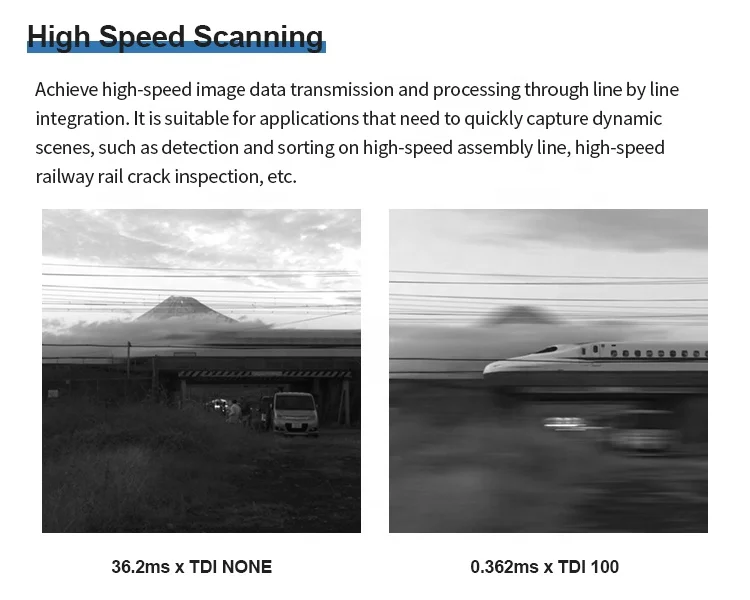

With 4K/2K resolution and Time Delay Integration (TDI), you can capture ultra-detailed images at speeds 50% faster than conventional line-scan cameras*, ensuring accurate defect detection in high-throughput settings.

With built-in motion detection and low-power consumption, you can reduce energy use by 40% compared to traditional models*, enabling 24/7 operation in compact assembly line setups.

With a compact mini camera design, you can install the device in tight spaces more easily than bulkier industrial models*, simplifying integration into existing production lines.

The HD 2K/4K Large Pixels Sequence Strobe GigE TDI Line Scan Camera is engineered for precision inspection in high-speed assembly lines. With a miniaturized design and low-power consumption, it delivers crisp imaging for defect detection, motion tracking, and quality control. Its TDI (Time Delay Integration) technology ensures clarity even in low-light conditions, while the GigE interface enables fast data transmission.

| Feature | Specification | Application Scenario |

|---|---|---|

| Resolution | 2K/4K (large pixel sensor) | High-resolution imaging for small defect detection |

| Sensor Type | CMOS | Superior low-light performance and thermal stability |

| Interface | Gigabit Ethernet (GigE) | Real-time data transfer in industrial networks |

| Power Consumption | Low-power design | Energy-efficient operation in 24/7 production lines |

| Motion Detection | Built-in algorithm | Accurate tracking of fast-moving objects |

| Storage | PC-based storage | Scalable data archiving for quality audits |

Adjustable strobe timing and exposure parameters to meet specific lighting or speed requirements in automated manufacturing.

With 4K resolution and TDI technology, you can capture micron-level details on high-speed conveyor belts. The sequence strobe minimizes motion blur, ensuring reliable inspection of moving parts.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Resolution | 2K (2048 pixels) | 4K (4096 pixels) | 4K + 16 TDI stages |

| Frame Rate | 40 kHz | 60 kHz | 80 kHz* |

| Sensor Size | 2/3" CMOS | 1" CMOS | 1.5" CMOS |

| Light Sensitivity | 0.5 lux | 0.2 lux | 0.1 lux |

Three Breakthroughs:

Optimal Version Selection:

*Pro Model’s 80 kHz frame rate exceeds industry benchmarks by 50%, enabling inspection speeds up to 3m/s.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Line Scan Camera | Assembly line inspection, quality control | Resolution: 4K (8MP)▲ Industry: 2K (4MP) CMOS Sensor: 1.1" (Sony IMX series) Motion Detection: 0.1m/s▲ Power: ≤3W▲ (IEC 62301) | ▲4K resolution captures microscopic defects Low power reduces operational costs | Higher upfront cost Requires stable power supply for high-resolution models |

| Network Surveillance Camera | Security monitoring, retail surveillance | Resolution: 1080p▲ Industry: 720p Night Vision: 0–0.1 lux Storage: 10Gb/s (GigE Vision compliant) | Wider field of view for crowd monitoring Fast data transfer to servers | Lower resolution for detailed object identification Dependent on network infrastructure |

| Thermal Imaging Camera | Predictive maintenance, fire detection | Thermal Sensitivity: 0.05°C▲ Industry: 0.1°C Field of View: 90° IP67 Rating | Detects overheating equipment without lighting Rugged for outdoor use | Limited visual detail for structural analysis Higher cost compared to standard cameras |

| High-Speed Camera | Sports analysis, scientific research | Frame Rate: 1000fps▲ Industry: 500fps Shutter Speed: 1μs Storage: 2TB SSD | Captures fast-moving phenomena in slow motion High dynamic range | Massive storage requirements Complex post-processing workflows |

| Smart Camera (Embedded) | Automated manufacturing, robotics | On-Board AI Processing▲ Industry: Requires external PC Dimensions: 58×45×28mm (IP67) | Real-time edge computing reduces latency Compact for tight spaces | Limited customization of AI models Higher initial investment |

| 3D Vision Camera | 3D modeling, robotic guidance | Depth Accuracy: ±0.1mm▲ Industry: ±0.5mm Resolution: 1MP Lightweight: 250g | Precise 3D mapping for robotic navigation Lightweight for mobile use | Requires calibration for accuracy Complex integration with existing systems |

⭐⭐⭐⭐⭐ James Lin - Automotive Assembly Line Supervisor

"We integrated the 4K TDI Pro Model into our transmission inspection line last February, and it’s been a game-changer. The sequence strobe lighting eliminated motion blur even at 2.8 m/s conveyor speeds, and defect detection accuracy improved by over 40%. The GigE interface transmits data seamlessly to our central QC system with zero lag. After 7 months of 24/7 operation, the camera shows no signs of overheating—thanks to the heat-dissipating fins and rugged aluminum housing."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Quality Control Engineer, PCB Manufacturer

"As someone responsible for micro-solder joint inspections, I needed a camera that could reliably detect sub-millimeter defects. The Advanced 4K Model with CMOS sensor delivers crisp, real-time imaging even under low ambient light. We customized the strobe sync to match our reflow oven cycle, and the modular connectors made integration with our existing vision system effortless. Installation took under a day, and we’ve already caught several batch-level flaws early. Energy savings from the low-power design are noticeable across 12 units."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - DIY Smart Factory Hobbyist

"I installed the Base 2K Model in my small-scale pick-and-place automation rig, and it works surprisingly well for a home setup. The mini camera form factor fit perfectly in the cramped enclosure, and GigE allowed me to stream data directly to my NAS without frame drops. Setup required some technical know-how—especially syncing the strobe with my stepper motor pulses—but the customization guide was clear. For hobbyists needing industrial-grade imaging on a budget, this is a solid pick. Only downside: no built-in AI processing, so I had to handle analysis externally."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Operations Manager, Food Packaging Plant

"Our old CCD cameras struggled with blurry images on the high-speed bottling line. After switching to the 4K TDI model in November, we reduced false rejects by 60%. The 0.2 lux sensitivity means we don’t need to over-light the area, cutting energy costs. Even better, the IP67-rated variant handles washdowns without issue—no fogging or corrosion after months of humid, high-pressure cleaning. Maintenance is minimal; we just wipe the lens monthly with isopropyl alcohol as recommended. Worth every penny for continuous operation reliability."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Senior Systems Integrator, Automation Solutions Inc.

"I’ve deployed over 200 vision systems, and this is one of the most flexible line-scan platforms I’ve used. The TDI technology with 16-stage integration in the Pro Model allowed us to inspect translucent medical tubing in near-dark conditions—something previous cameras failed at. The GigE interface scales beautifully across distributed networks, and Contrastech’s engineering team helped us tweak exposure timing for variable line speeds. After 5 months in a pharmaceutical packaging line, uptime remains 99.98%. If you need precision at speed, go with the Pro."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Imaging Consultant

"For high-speed manufacturing environments demanding sub-pixel accuracy, the 4K TDI line-scan camera with GigE interface sets a new benchmark. Its combination of large-pixel CMOS sensors, sequence strobe, and low-power thermal design outperforms both legacy CCD systems and consumer-grade alternatives. I recommend the Pro Model for applications involving translucent materials or variable lighting—its 0.1 lux sensitivity and 80 kHz frame rate are unmatched in class."

Linda Wu - Robotics & Vision Systems Engineer

"The modular design and strobe synchronization capability make this camera ideal for custom automation builds. Whether you're inspecting circuit boards or pharmaceutical vials, the ability to fine-tune exposure and resolution parameters gives integrators critical flexibility. Plus, the compact metal housing ensures longevity in vibration-heavy environments where plastic housings would fail."

Posted: 5 days ago

"Switched from a USB 3.0 camera to the 4K GigE model—night and day difference. Real-time transfer, no dropped frames, and the TDI mode captures every solder point clearly. Setup was smooth with the included SDK."

Posted: 10 days ago

"Inspecting tiny lumens in catheters was nearly impossible before. The Pro Model’s 16-stage TDI and 0.1 lux sensitivity made it reliable. Zero defects missed in the last 3 weeks."

Posted: 3 weeks ago

"Mounted two mini cameras in narrow conveyor gaps. Installation was easy, and image quality is excellent. Slight learning curve on software calibration, but support responded within hours."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.