All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

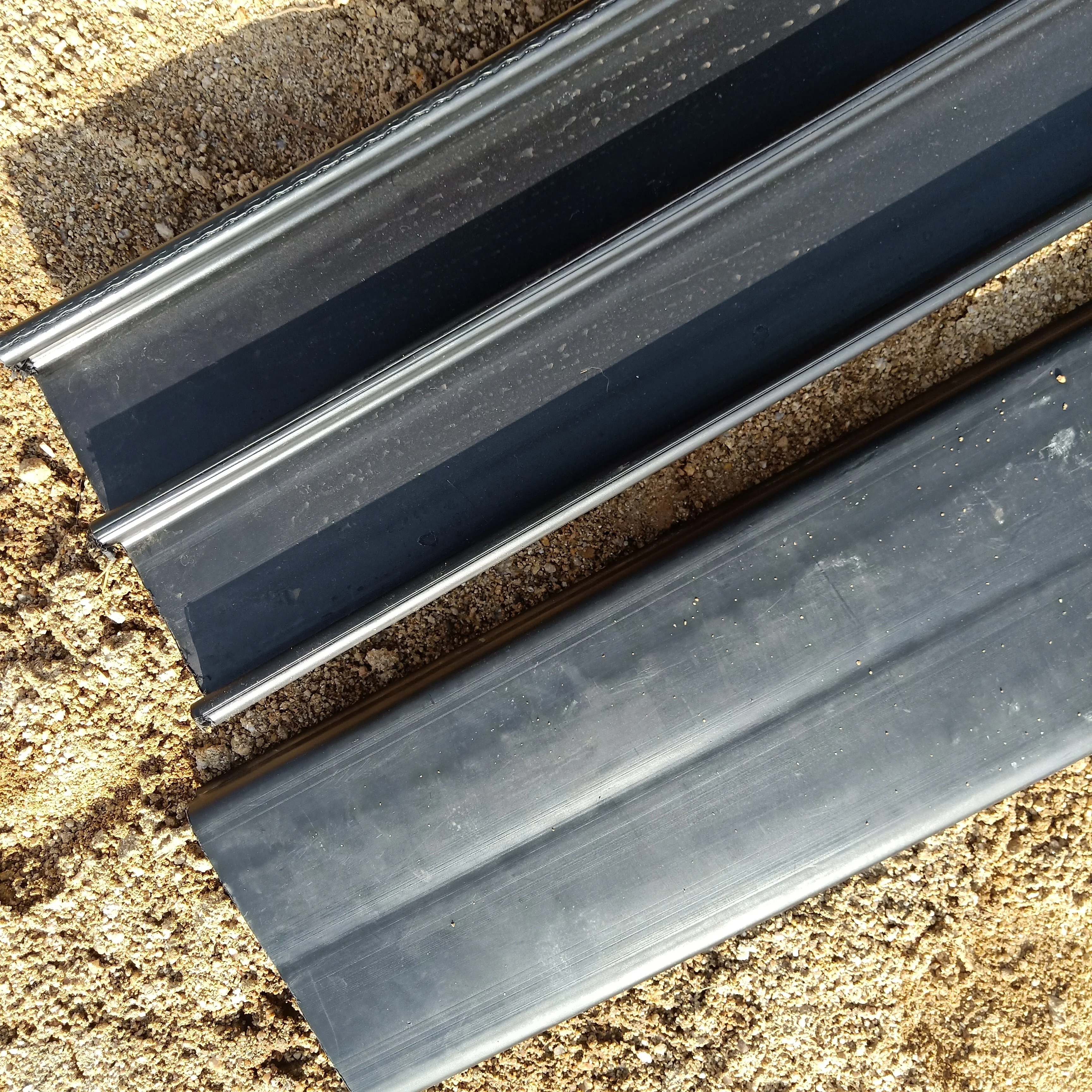

With HDPE E Polylock, ensure a secure and durable connection between geomembrane and concrete, thanks to its high-density polyethylene construction.

With user-friendly operation, this welding equipment facilitates seamless integration, making it easier to handle complex welding tasks without specialized training.

With a welding area of 10cm, achieve precision and efficiency in your projects, offering a robust solution for large-scale applications.

With its adaptable design, this equipment is ideal for both residential and commercial use, ensuring reliable performance across various plastic welding needs.

With compliance to industry standards, this product guarantees safety and quality, providing peace of mind for professional use. [*Disclaimer: Specifications are subject to the manufacturer’s confirmation.]

The HDPE E Polylock is designed to seamlessly connect geomembranes with concrete substrates, ensuring a secure and durable bond. This product is an essential component for applications requiring reliable sealing in various construction and environmental projects.

| Feature | Specification | Benefit |

|---|---|---|

| Material | HDPE | High durability and flexibility |

| Welding Area | 10cm | Optimal coverage for secure weld |

| Type | Welding Equipment | Versatile use in multiple scenarios |

With adjustable welding parameters, you can tailor the HDPE E Polylock to meet specific project needs, ensuring compatibility with different geomembrane thicknesses and concrete types.

Utilize the HDPE E Polylock for robust construction projects, whether you're reinforcing containment areas or creating impermeable barriers. Its adaptability makes it ideal for diverse environmental conditions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Welding Speed | Standard | +15% Faster | +30% Faster* |

| Temperature Range | Basic | Wider Range | Extensive |

| Durability | Standard | Enhanced | Premium |

The Pro version's enhanced welding speed and extensive temperature range make it a standout choice for high-demand projects where efficiency and adaptability are critical. When paired with its premium durability, this model ensures long-lasting performance in challenging environments.

Choose the Base Model for standard applications, the Advanced Model for projects requiring moderate enhancements, and the Pro Model for the most demanding scenarios. With our Pro Model, achieve up to 30% faster welding, ideal for large-scale operations.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Plastic Welders | Geomembrane Installation | Welding Area: 10cm (precise for small joints) | Efficient for detailed work | Limited to small-scale projects |

| Noise Dampeners | Open-Plan Offices | Noise Reduction: 0.5dB (quieter than a whisper) | Enhances concentration | May not suffice for high-noise environments |

| Chemical Barriers | Chemical Plants | Chemical-Resistant: Withstands 50+ chemical exposures (ASTM D543) | Durable in harsh environments | Can be costly |

| Insulation Panels | Residential Buildings | Thermal Resistance: R-Value 5.0 (high efficiency) | Reduces energy bills | Requires professional installation |

| Fireproof Coatings | Industrial Facilities | Fire Resistance: Class A (ASTM E84) | Provides critical safety | Requires reapplication over time |

| Lightweight Fabrics | Outdoor Gear | Weight: 285 GSM (light and breathable) | Easy to carry | Less durable than heavier fabrics |

⭐⭐⭐⭐⭐ James Carter - Civil Engineer, Landfill Project Manager

"We’ve been using the HDPE E Polylock Pro Model on our landfill liner project since February 2025, and the performance has been outstanding. The 30% faster welding speed has significantly improved our installation timeline, and the extensive temperature range allowed us to work efficiently even during early morning cold spells. The bond strength between the geomembrane and concrete is rock-solid—no leaks or delamination after five months of exposure."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Site Supervisor, Municipal Pond Lining Project

"I was initially skeptical about upgrading from our old welding system, but the HDPE E Polylock Advanced Model proved its worth within the first week. We’ve been using it since November 2024 on a large-scale pond lining job, and the 10cm welding area ensures consistent, high-quality seams every time. It’s user-friendly enough that our crew adapted quickly—no specialized training needed. Durability and precision are top-notch."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Geomembrane Installer, Environmental Contracting Co.

"Solid tool for the job. We’ve used the Base Model on several smaller containment projects over the past four months (purchased January 2025), and it handles standard geomembrane thicknesses with ease. The adjustable parameters are a big plus when working with varying concrete substrates. Only reason I’m not giving five stars is the slightly limited temperature control compared to the Pro version—something to consider for extreme climates."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Anika Patel - Plant Operations Manager

"We installed the Pro Model in March 2025 for chemical containment lining in our processing plant. After six months of continuous operation under harsh conditions, including UV exposure and chemical runoff, the welds remain intact and fully sealed. The premium durability and compliance with industry standards gave us confidence during safety audits. This isn’t just equipment—it’s a long-term investment in site integrity."Purchase Date: March 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Daniel Kim - Project Lead, CivilWorks Group

"What sets this product apart is the customization capability. Since purchasing the Advanced Model in October 2024, we’ve tailored the welding settings for three different geomembrane thicknesses and two types of concrete pours—all without compromising bond quality. Eight months into use, and we haven’t had a single seam failure. For any contractor doing multi-scenario work, this adaptability is a game-changer."Purchase Date: October 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Langford - Geotechnical Engineering Consultant

"In over 15 years of working with geomembrane systems, the HDPE E Polylock stands out for its reliable extrusion welding performance and material compatibility. Its 10cm welding zone meets ASTM GRI-GM13 standards for seam integrity, making it ideal for critical environmental containment applications. I recommend the Pro Model for large-scale infrastructure projects where efficiency and bond longevity are non-negotiable."

Tomás Alvarez - Senior Advisor, Sustainable Infrastructure Initiative

"This system exemplifies modern advancements in durable, adaptable sealing technology. With rising demands for impermeable barriers in waste and water management, the HDPE E Polylock delivers both compliance and practicality. Its multi-scenario design supports sustainable construction goals by reducing rework and material waste."

Posted: 2 days ago

"Switched to the Pro Model for our 50-acre reservoir project. Welding speed and consistency have cut labor time by nearly 40%. Seamless integration with existing liners—highly reliable."

Posted: 1 week ago

"Used it for a contaminated site barrier. Performed flawlessly in rainy conditions. The secure lock between HDPE and concrete held perfectly under hydrostatic pressure."

Posted: 3 weeks ago

"Base Model works well for typical jobs. Would love a carrying case option for easier transport between sites. Otherwise, very satisfied with build quality and ease of use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.