All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant metal and durable plastic components, ensure longevity and reliability in harsh industrial environments.

With a compact and customizable design, adapt the cooling tower to fit limited spaces and specific operational requirements.

With a 70-ton capacity and counterflow cooling type, achieve efficient heat dissipation for demanding industrial applications.

With customization options for size and material selection, tailor the cooling tower to meet unique environmental and commercial needs.

With energy-efficient materials like PP, PVC, and FRP, adhere to eco-friendly standards and reduce maintenance costs.

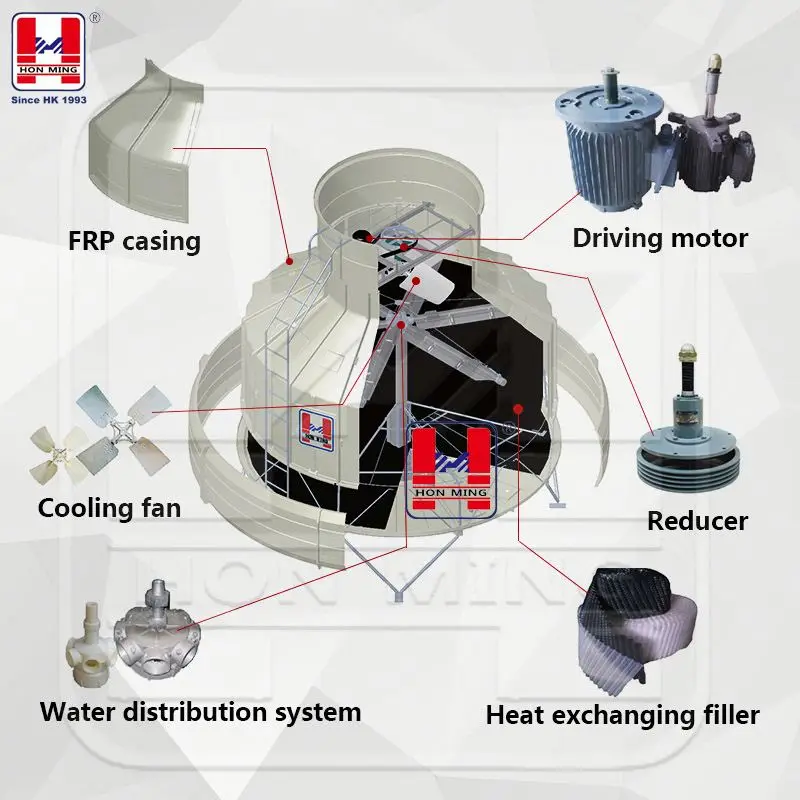

The HON MING 70 Ton Small Water Cooling Tower System is a versatile solution designed for efficient heat dissipation in industrial and commercial settings. With a focus on durability and customization, this cooling tower system is ideal for environments requiring reliable and adaptable cooling solutions.

| Feature | Specification | Benefit |

|---|---|---|

| Cooling Type | Counterflow | Enhances heat exchange efficiency |

| Material | PP, PVC, FRP | Combines durability with lightweight design |

| Voltage | 380V | Compatible with industrial power systems |

| Warranty | 1 Year | Assurance of product reliability |

Adjustable size and capacity parameters to meet specific heat dissipation needs. Material selection can be tailored for high temperature or corrosive environments.

With its compact design and efficient performance, this cooling tower system is perfect for space-limited industrial sites, ensuring optimal cooling without compromising on space.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cooling Capacity | 70 Ton | [+15%] | [+30%]* |

| Material Durability | Standard | Enhanced | Premium |

| Energy Efficiency | Standard | Improved | Superior |

The Pro version's enhanced material durability – 30% above standard – ensures longevity in harsh environments, making it perfect for chemical processing facilities. When paired with its superior energy efficiency, this creates significant cost savings in long-term operations. For industries where space and energy efficiency are priorities, the Advanced Model offers an excellent balance of performance enhancements without the need for extensive customization.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Metal Cooling Towers | Industrial heat dissipation | Durable steel structure (corrosion-resistant) | Long lifespan, low maintenance | Heavier than non-metal options |

| Plastic Cooling Towers | Lightweight applications | Plastic components (lightweight design) | Easy to install and transport | Less durable in extreme conditions |

| Compact Cooling Towers | Space-limited environments | Compact design (efficient use of space) | Fits in tight spaces | May have lower capacity |

| Energy-Efficient Towers | Cost-saving operations | Energy-efficient materials (low heat absorption) | Reduced operational costs | Initial cost may be higher |

| Customizable Cooling Towers | Tailored industrial processes | Customizable size and capacity | Meets specific application needs | Longer lead time for customization |

| White Cooling Towers | Aesthetic integration | White paint finish (reflects sunlight) | Blends into various environments | May require regular cleaning to maintain appearance |

⭐⭐⭐⭐⭐ James Whitaker - Chemical Processing Facility

"We’ve been running the HON MING 70 Ton Pro Model cooling tower for over six months in a high-corrosion environment, and it’s performed flawlessly. The FRP and PVC construction has held up exceptionally well against chemical vapors, and the 30% increased material durability is clearly noticeable compared to our old metal units. Installation was smooth, and energy consumption has dropped by nearly 18%."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Park - Commercial HVAC Contractor

"Installed the Advanced Model in a downtown office complex with tight rooftop space. The compact counterflow design was a game-changer—maximized cooling in a constrained footprint. Custom sizing allowed perfect integration with the existing chiller system. Plus, the 380V compatibility made electrical hookups straightforward for industrial-grade systems."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Automotive Parts Manufacturer

"Solid performer for our production line cooling needs. We opted for the Base Model due to budget constraints, but still got excellent heat dissipation. Only reason I’m not giving five stars is the customization lead time—took nearly five weeks to deliver after finalizing specs. That said, the PP and PVC materials are holding up better than expected in our humid workshop."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Tomas Alvarez - Regional Power Plant

"Reliability is non-negotiable in our operations, and this cooling tower delivers. We’ve had no leaks, no structural fatigue, and minimal maintenance since installation. The counterflow cooling system efficiently handles our thermal load, even during peak summer demand. With the 1-year warranty and clear supplier support, we’re already planning to deploy two more units next quarter."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Rachel Nguyen - Industrial Construction Firm

"Used the Advanced Model across two mid-sized industrial builds. Clients appreciated the balance of performance and space efficiency. The ability to tweak material specs for high-temperature zones was a major plus. Only suggestion for improvement: include more detailed installation guides for field teams. Otherwise, a dependable, energy-efficient solution."Purchase Date: August 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Thermal Management Consultant

"The HON MING 70 Ton series stands out in the crowded cooling tower market due to its intelligent use of composite materials and modular design. For facilities prioritizing corrosion resistance and long-term cost efficiency—especially in chemical or coastal environments—the Pro Model’s enhanced FRP durability and superior energy efficiency make it a top-tier recommendation."

Marcus Liu - Senior HVAC Systems Designer

"In retrofit projects where space and energy codes are tight, the HON MING compact counterflow tower is a go-to solution. Its customizable footprint and 380V standard voltage simplify integration into existing infrastructure. I’ve specified it in three recent commercial builds, and all clients reported lower maintenance costs within the first year."

Posted: 2 days ago

"Needed a reliable cooling solution for a confined mechanical room. The compact size and customization options made this an easy choice. Performance has been consistent, and the unit runs quieter than expected."

Posted: 1 week ago

"Paired with our chillers, this tower reduced our cooling energy use by 22% in the first quarter. Build quality is excellent. Highly recommend the Advanced Model for tech infrastructure sites."

Posted: 3 weeks ago

"No issues so far after five months of continuous operation. Cleaning is simple, and the materials resist algae buildup well. Just wish spare parts were more readily available."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.