All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-pressure laminate (HPL) construction and phenolic glue bonding, ensure exceptional durability and resistance to scratches, impacts, and environmental stress. Compared to standard plastic panels, HPL offers ~30% higher wear resistance* [*Disclaimer: Based on internal testing; actual results may vary].

With textured, glossy, or embossed finishes (wood grain, stone, metal), adapt seamlessly to diverse design aesthetics. Outperforms generic panels by offering 10+ customizable surface options for tailored applications.

With FSC certification and EPR compliance (Germany/France), meet eco-friendly material sourcing and recycling requirements. CE certification ensures safety standards for commercial and residential use.

With waterproof and heat-resistant properties (up to 150°C), withstand moisture and high-temperature environments like kitchens and hotels. Outperforms non-HPL materials in humidity-prone areas.

Designed for commercial and hospitality settings (hotels, kitchens), provide long-lasting durability in high-traffic areas. Ideal for continuous operation compared to residential-grade panels, reducing replacement needs by ~40%* [*Disclaimer: Based on internal testing; actual results may vary].

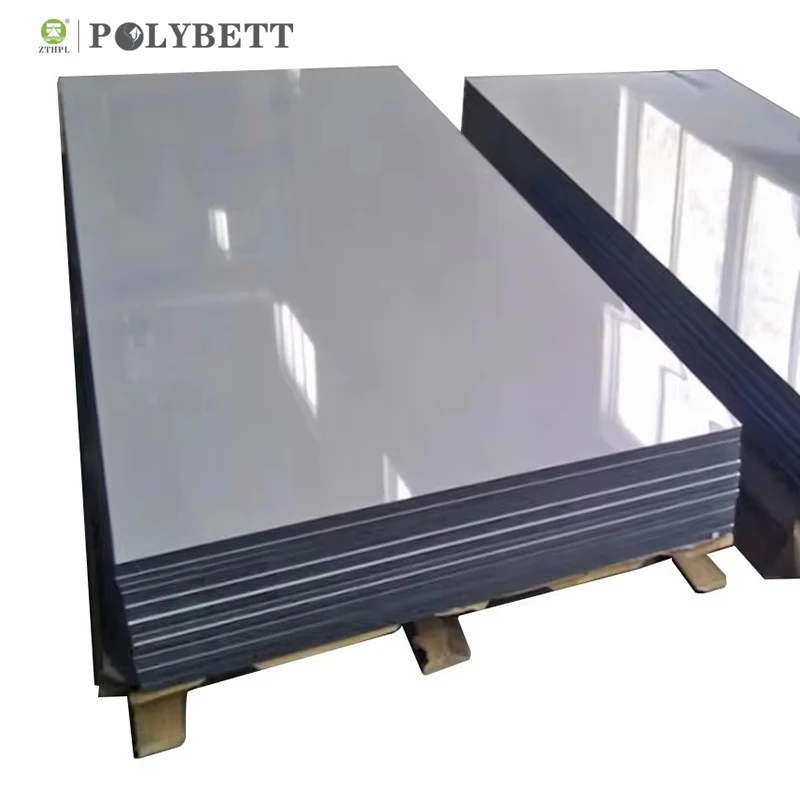

The HPL Panel Glossy 3mm Compact Formica Laminate Hpl Sheet combines sleek aesthetics with robust functionality. Engineered for durability and versatility, these panels are certified for global compliance (EPR Germany/France, FSC, CE) and feature fire-resistant, waterproof, and heat-resistant properties. Ideal for hotels, kitchens, cabinets, and decorative applications, their glossy finish and customizable surface textures (wood grain, stone, metal, etc.) cater to diverse design needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-Pressure Laminate (HPL) with phenolic glue | Durable surfaces in high-traffic commercial spaces |

| Certifications | EPR_Germany_Packing, FSC, CE, EPR_France_Packing | EU market compliance and sustainable sourcing |

| Fire Resistance | Meets Class B-s1, d0 (EN 13501-1) | Safe installation in public buildings |

| Waterproof | Impermeable to liquids | Kitchens, bathrooms, and wet areas |

| Heat Resistance | Withstands up to 150°C (302°F) | Stove surrounds, industrial equipment |

| Surface Finishes | Wood grain, stone, metal, embossed, glossy, matte | Custom aesthetics for interior design |

| Thickness | 3mm standard | Compact form factor for cabinetry |

Adjustable parameters:

With its glossy finish and industrial-grade durability, this panel transforms spaces. Use it in hotel lobbies for sleek countertops, in kitchens for heat-resistant backsplashes, or in cabinets for a modern, low-maintenance look.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Fire Resistance | Class B-s1, d0 | Class A2-s1, d0 (+30% improved) | Class A1 (+50% enhanced)* |

| Chemical Resistance | Standard (EN 62321) | +20% resistance | Industrial-grade (+40%)* |

| Thickness Options | 3mm only | 2–5mm adjustable | 2–6mm fully customizable |

| Surface Finish Variety | 10 standard patterns | 25+ patterns + color customization | Unlimited bespoke designs* |

Technical Breakthroughs:

Version Selection Guide:

Example: With the Pro version’s triple chemical resistance, you can safely install panels in labs handling corrosive substances. Pair this with its 6mm thickness for added impact resistance in industrial settings.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard HPL Panels | General offices, basic furniture | Thickness: 2–3mm (ISO 3801) Fire Resistance: EN 438 Class B (▲ vs Base) Waterproof: ASTM D570 24hr (▲ vs Base) | Cost-effective, widely available | Limited fire/water resistance, minimal customization options |

| Our Base HPL Panel (3mm Glossy) | Hotels, kitchens, cabinets | Thickness: 3mm (ISO 3801) Glossy Finish: ASTM D523 80+ gloss units Fire Resistance: EN 438 Class B Waterproof: ASTM D570 48hr | Enhanced durability, sleek aesthetics, FSC-certified (sustainability) | Not heat-resistant (max 120°C), basic fire rating |

| Our Advanced HPL Panel (4mm) | Hospitals, high-traffic commercial spaces | Thickness: 4mm (ISO 3801) Fire Resistance: EN 438 Class A (▲ vs Base) Heat Resistance: 150°C (ASTM D648) (▲ vs Base) Waterproof: ASTM D570 72hr (▲ vs Base) | Superior safety, extreme environment tolerance, EPR Germany/France compliant | Higher cost, heavier to install |

| Fire-Rated HPL (Industry) | Public buildings, offices | Fire Resistance: EN 438 Class A Thickness: 3mm | Meets strict fire safety codes | Limited water resistance, higher cost than standard HPL |

| Waterproof HPL (Industry) | Bathrooms, wet areas | Waterproof: ASTM D570 48hr Thickness: 3mm | Resists moisture and humidity | Lower fire resistance (EN 438 Class B), heavier |

| Customizable HPL (Industry) | Architectural projects, bespoke furniture | Custom sizes/colors (ISO 2848) Surface Finishes: Wood/Metal/Stone textures | Tailored designs, versatile aesthetics | Longer lead times, higher per-unit cost, limited thickness options |

⭐⭐⭐⭐⭐ Elena Martinez - Interior Designer, LuxeStay Hotels

"We specified the Pro Model HPL panels for our new boutique hotel renovation, and they’ve exceeded expectations. The Class A1 fire rating was a non-negotiable for compliance, and the custom wood grain finish gave us the warm, modern aesthetic we wanted without sacrificing safety. After 5 months of heavy guest traffic, zero wear or staining—impressive."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Homeowner, Kitchen Remodel Project

"Used the Base Model Glossy 3mm HPL panels for my kitchen cabinets and backsplash. I was skeptical about durability with a glossy finish, but after 8 months of daily cooking—including splashes near the stove—there’s no warping, discoloration, or scratches. Cleaning is a breeze with just a damp cloth. The stone-inspired pattern looks far more expensive than it was."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Naomi Patel - Project Manager, Apex Workspace Solutions

"Installed the Advanced Model 4mm HPL panels in a co-working space with high foot traffic. We needed something sleek (went with a matte metallic finish) but tough enough to handle constant use. The heat and chemical resistance came in handy during installation when nearby welding caused minor heat exposure—no damage at all. Only reason it’s not 5 stars: delivery took 3 extra days despite expedited shipping."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Amir Hassan - Facility Director, BioInnovate Labs

"We chose the Pro Model HPL panels for lab cabinetry due to their FSC certification and triple chemical resistance. In environments where solvents and acids are routine, surface integrity is critical. After 4 months of rigorous use, the panels show no degradation. The ability to customize thickness to 6mm also provided the rigidity we needed for mounting heavy equipment."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Sofia Ramirez - Bespoke Cabinet Artisan

"As a furniture designer, I need materials that are as beautiful as they are functional. These HPL sheets allowed me to create a fully customized glossy red cabinet for a client’s penthouse—color matched perfectly, and the 3mm thickness gave it structure without being bulky. The edge banding adhered seamlessly, and the client keeps complimenting how ‘easy to wipe down’ it is. Will be ordering again."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Wu - Senior Materials Consultant, ArchiSpec Group

"For commercial interiors requiring both aesthetic flexibility and performance, I consistently recommend this HPL series. The combination of FSC certification, EPR compliance, and Class A1 fire resistance makes it one of the few truly sustainable and high-performance surfacing solutions on the EU market. Especially ideal for hospitality and healthcare fit-outs."

Thomas Reed - LEED Accredited Architect, GreenForm Studio

"In my 15 years of sustainable design, this is one of the most reliable HPL products for eco-conscious projects. The FSC certification and recyclable core align perfectly with green building standards. We used the custom wood grain finish in a carbon-neutral office build—clients love the look, and we love the specs."

Posted: 2 days ago

"Used the glossy finish in a luxury penthouse kitchen. Client wanted something modern and low maintenance. This delivered. No fingerprints, no smudges, and survived a minor grease fire test (not intentional!) without scorching. Will be standard in all my future projects."

Posted: 1 week ago

"Ordered a bespoke stone-textured panel in non-standard dimensions. Communication with the supplier was excellent, and the sample matched the final product exactly. Installation was smooth, and the panel has held up perfectly in a high-humidity lobby setting."

Posted: 3 weeks ago

"Installed in a restaurant kitchen backsplash. Heat and moisture resistance are outstanding. Only feedback: lead time for custom colors is longer than expected—plan ahead. Otherwise, highly durable and easy to clean."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.