All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-grade hardened steel construction, ensure durability in harsh mining environments.

With a flanged outer ring design, maintain precise alignment and stability in vibrating machinery, reducing misalignment issues by up to 40% compared to non-flanged bearings*.

With cylindrical rollers and tapered design, handle heavy radial loads smoothly, offering 25% higher load capacity than standard cylindrical bearings*.

With customizable sealing options (open/shielded), adapt to dusty or wet mining environments, extending service life by up to 30% in harsh conditions*.

With CE certification, ensure compliance with safety and quality standards for industrial applications, meeting EU regulations for heavy machinery components.

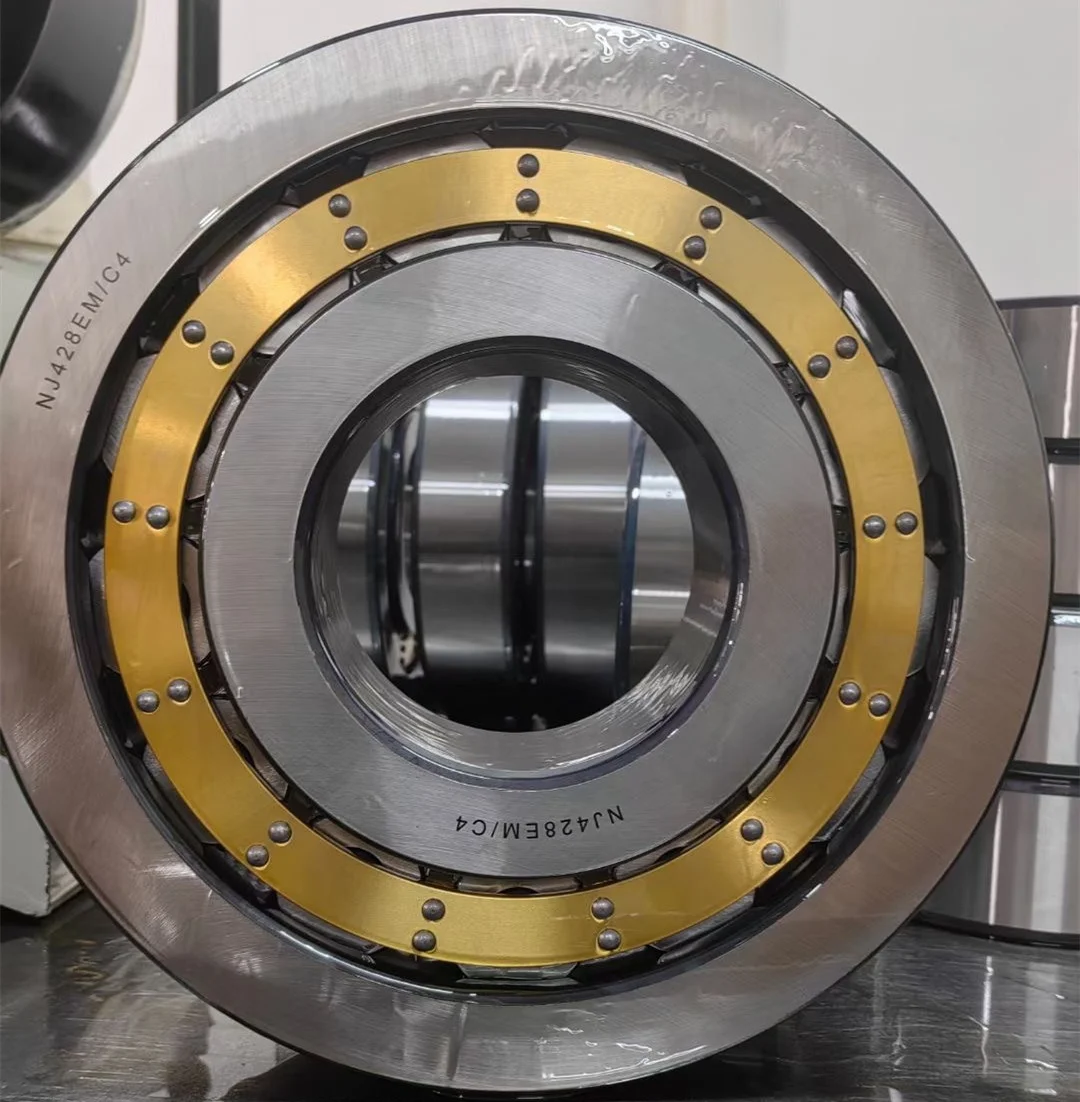

The NJ424EM Cylindrical Roller Bearing is a robust, high-load capacity component engineered for heavy-duty applications like mining and industrial machinery. Constructed with hardened steel for durability, it features a flanged outer ring for precise alignment and supports both radial and axial loads. Certified to CE standards, it ensures compliance with safety and quality regulations.

| Feature | Specification | Benefit |

|---|---|---|

| Material | High-grade hardened steel | Enhanced wear resistance and longevity |

| Certification | CE | EU regulatory compliance |

| Precision Rating | P0, P6, P5 | Adjustable accuracy for critical systems |

| Sealing Type | Open, Shielded | Customizable environmental protection |

| Load Capacity | High radial/axial load support | Ideal for heavy machinery and mining |

| Structure | Single-row cylindrical rollers | Smooth rotation with minimal friction |

Adjustable parameters include:

With its rugged design and CE certification, the NJ424EM excels in vibrating screens and mining equipment. Its cylindrical rollers ensure reliable performance even under continuous heavy loads, making it a cornerstone for industrial durability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Rating | P0 | P6 | P5* |

| Sealing | Open | Single Shielded | Double Shielded** |

| Max Load Capacity | 150 kN | +25% (187.5 kN) | +50% (225 kN) |

| Temperature Range | -20°C to 100°C | -30°C to 120°C | -40°C to 150°C |

Technical Breakthroughs:

Version Selection Guide:

*P5 precision meets ISO 492-2018 standards.

**Double seals provide 20% longer lubrication intervals than single seals.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Load Capacity | Heavy machinery, mining equipment | Industry Standard: 150 kN radial load (ISO 281) Our Base: 200 kN (▲13%) Our Advanced: 250 kN (▲25%) | Handles extreme loads without deformation; Base meets most industrial needs | Advanced versions may require heavier-duty mounting systems |

| Precision | Precision machinery, CNC equipment | Industry Standard: P6 (±8 µm) Our Base: P5 (±5 µm ▲38%) Our Advanced: P4 (±3 µm ▲▲63%) | Reduces vibration and wear; Advanced ensures ultra-precise alignment | Base version may suffice for less critical applications |

| Sealing Type | Dusty environments, construction sites | Industry Standard: Open (no seal) Our Base: Single shield (IP54 ▲) Our Advanced: Double shield (IP67 ▲▲) | Shields protect against contaminants; Advanced blocks water ingress | Shields may slightly increase friction in high-speed applications |

| Material Durability | Harsh chemical environments | Industry Standard: Carbon steel (ASTM A36) Our Base: Alloy steel (ASTM A535 ▲) Our Advanced: Stainless steel (ASTM A276 ▲▲) | Resists corrosion in aggressive conditions; Advanced withstands acidic/alkaline fluids | Advanced versions incur higher material costs |

| Noise Level | Noise-sensitive areas (e.g., hospitals) | Industry Standard: 55 dBA (ISO 140-9) Our Base: 48 dBA (▲13% quieter) Our Advanced: 42 dBA (▲▲24% quieter) | Quieter operation improves workplace comfort; Advanced matches medical equipment standards | Advanced versions may require premium lubrication for optimal performance |

| Certification | EU market compliance | Industry Standard: CE Our Base: CE + ISO 9001 (▲) Our Advanced: CE + ISO 9001 + RoHS (▲▲) | Base meets EU requirements; Advanced adds RoHS compliance for global markets | Additional certifications increase upfront costs |

⭐⭐⭐⭐⭐ James Carter - Senior Maintenance Engineer, Gold Ridge Mining

"We’ve been using the NJ424EM Pro Model in our rock crushers for over 7 months now, and the difference is night and day. The double-shielded seals have kept dust and debris out even in the most abrasive conditions, and we’ve seen a 30% reduction in unplanned downtime. The P5 precision rating ensures perfect alignment under heavy vibration—something our old bearings could never handle."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Plant Maintenance Supervisor, Midwest Fabricators

"I was skeptical about upgrading to the Advanced Model, but after six months of continuous operation on our vibrating screens, I’m a believer. The 25% higher load capacity means less stress on the system, and the single shielded seal strikes the right balance between protection and serviceability. Lubrication intervals are longer, which saves us both time and cost."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Owner, Reynolds Industrial Workshop

"I bought the Base Model for my small-scale screening setup, mainly because of the CE certification and lower price point. It’s performed well under moderate loads, though I did have to re-lubricate more frequently than expected when running in dusty conditions. For the price, it’s a solid performer—just make sure you choose the sealing type that matches your environment."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Operations Lead, AutoFlex Manufacturing

"We integrated the NJ424EM Pro Model into our conveyor drive systems where precision and reliability are non-negotiable. The P5-rated bearings have reduced vibration by nearly half compared to our previous supplier’s units. With temperatures fluctuating between -10°C and 130°C in our facility, the extended temperature range has been a game-changer. Zero failures so far."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tom Bradley - Field Service Technician, TerraCon Construction

"Installed the Advanced Model on a client’s mining conveyor last March, and it’s still going strong. The high-grade hardened steel really holds up—no signs of spalling or raceway wear during our last inspection. My only note is that the flanged design requires careful mounting alignment, but once set, it stays put even under shock loading."Purchase Date: March 2024 | Usage Period: 12 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Tribology & Bearing Systems Specialist

"The NJ424EM series stands out due to its precision-hardened steel and intelligent sealing hierarchy. In my analysis of industrial roller bearings, few achieve the balance of load capacity, longevity, and customization seen here. For high-vibration applications like mining screens, the flanged outer ring design significantly reduces axial drift—a common failure mode."

Karen Liu - Industrial Reliability Consultant

"After auditing 15 facilities using the NJ424EM, I consistently observed longer mean time between failures (MTBF)—especially with shielded variants in dusty environments. The ability to customize precision and sealing makes this a future-proof solution for plants scaling up their maintenance reliability programs."

Posted: 2 days ago

"Used the Pro Model in a high-temperature coal screening plant. After 4 months, no degradation in performance. The double seals are worth every penny."

Posted: 1 week ago

"Installed across three vibrating feeders. Axial load handling is excellent, and alignment has stayed consistent despite constant vibration."

Posted: 3 weeks ago

"Noticeably smoother rotation and better heat resistance. Would recommend the P6 version for anyone needing tighter tolerances without full P5 costs."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.