All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

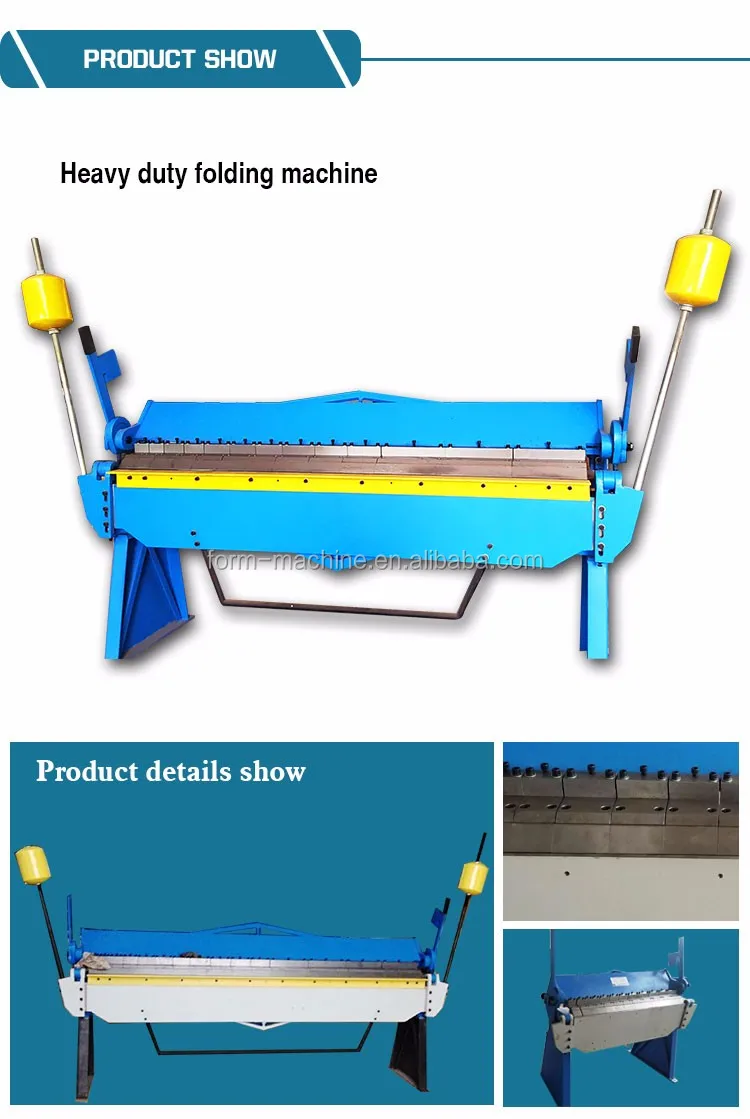

With a robust carbon steel frame, ensure stability and longevity when bending thick metal sheets. This material choice guarantees resistance to deformation under heavy loads, making it ideal for industrial and commercial applications.

With segmented adjustable guides, you can set bending angles to exact specifications, enabling precise fabrication of shapes like boxes, pans, and architectural components.

With hand-powered operation, bend metal sheets without relying on electricity, offering cost-effective and portable performance for workshops, construction sites, or on-demand fabrication tasks.

With compatibility for steel, aluminum, and copper sheets, adapt to a wide range of projects—from automotive parts to appliance components—ensuring broad usability across industries.

With a portable and compact build, operate seamlessly in tight spaces or remote locations. Its sturdy yet lightweight frame simplifies transportation while maintaining precision.

The Heavy Duty Manual Sheet Folding Machine is a robust, portable tool designed for precise bending of sheet metal into customized shapes. Built with a sturdy carbon steel frame and adjustable guides, it supports manual operation for controlled fabrication of pans, boxes, and structural components.

| Feature | Specification | Application Scenario |

|---|---|---|

| Frame Material | Heavy-duty carbon steel construction | Ensures stability for bending thick metal sheets in workshops |

| Adjustable Guides | Adjustable up to 180° with segmented stops | Precision bending for automotive parts and construction components |

| Safety Features | Integrated guards and manual force control | Safe operation in industrial environments |

| Material Compatibility | Supports carbon steel, aluminum, copper, and stainless steel | Versatile use in appliance, automotive, and architectural fabrication |

| Power Source | Manual operation (hand brake) | Low-energy, portable use in small workshops or on-site fabrication |

Adjustable angle guides allow customization of bend angles to meet specific project requirements, such as creating 90° corners for storage boxes or curved panels for architectural designs.

With segmented folding capabilities, this machine enables precise 90° bends for constructing metal boxes or decorative angles for industrial enclosures. Ideal for small-scale workshops needing flexibility without sacrificing durability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Sheet Thickness | 2mm | 3mm (+50% capacity) | 4mm (+100% capacity) |

| Angle Precision | ±5° | ±3° (+40% accuracy) | ±1° (+80% accuracy) |

| Adjustable Segments | 4 segments | 6 segments | 8 segments |

| Warranty | 1 year | 2 years | 3 years |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 4mm capacity, you can handle thicker stainless steel sheets for heavy machinery enclosures. Pair its segmented guides with carbon steel durability to create complex architectural panels.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Manual Bending Machines | Small workshops, DIY projects | - Manual force operation - Max sheet thickness: 3mm (ASTM A36 steel) - Material compatibility: steel, aluminum, copper | ▲ Cost-effective ▲ Portable (200kg compact design) Low power dependency | Limited capacity Requires physical effort No automation assistance |

| Hydraulic Bending Machines | Medium-scale fabrication, automotive parts | - Hydraulic power (50-ton capacity) - Max thickness: 6mm (ASTM A537 steel) - Adjustable angle guides (±1° accuracy) | ▲ Higher capacity Fast production Consistent bends | High energy consumption Complex maintenance Expensive upfront cost |

| CNC Bending Machines | Precision manufacturing, aerospace | - Computer-controlled bending - Accuracy: ±0.1mm (ISO 9001 certified) - Max thickness: 8mm (ASTM A569 steel) | ▲ Precision automation Repeatable results Multi-axis flexibility | High cost Requires skilled operators Large footprint |

| Portable Hand Brakes | On-site construction, field repairs | - Lightweight (20kg) - Max thickness: 2mm (ASTM A1011 steel) - Manual angle adjustment | ▲ Ultra-portable Affordable No power required | Low capacity Less durable over time Limited material versatility |

| Press Brake Machines | Heavy industrial, large-scale production | - High tonnage (100+ tons) - Max thickness: 10mm (ASTM A569 steel) - CNC-compatible options available | ▲ Mass production capability Handles heavy materials Scalable solutions | Enormous size High energy use Requires dedicated space and training |

| CNC Press Brake Machines | Automotive, aerospace, high-volume manufacturing | - CNC precision: **0.05mm accuracy (ISO 2768) - Max thickness: 12mm (ASTM A569) - Auto-calibration systems | ▲ Ultimate precision Full automation Reduced labor costs | Most expensive High maintenance costs Requires advanced software integration |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Shop Owner

"This manual folding machine has been a game-changer for our small shop. We upgraded to the Advanced Model for its 3mm capacity and ±3° precision—perfect for HVAC ducts and custom brackets. The adjustable segmented guides make multi-angle bends effortless, and the carbon steel frame feels rock-solid even after months of daily use. No electricity needed, which saves on overhead. Exactly what we needed for precision without the CNC price tag."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Emily Tran - Home Workshop Hobbyist

"I was skeptical a manual brake could handle anything beyond thin aluminum, but this little beast bent 2mm steel like butter. I built a custom tool cabinet and even some decorative copper panels for my garage. The compact design fits perfectly in my shed, and the safety guards gave me peace of mind as a beginner. Setup was quick, and the angle guides are intuitive. For the price, it’s an absolute steal."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Field Fabricator, Commercial Contractor

"We use the Base Model on job sites for quick bends in flashing, brackets, and enclosure frames. Lightweight enough to carry in a truck bed, yet durable enough to handle repeated use. The real win is portability and no power requirement—we’ve used it on rooftops and remote builds where generators aren’t feasible. Only reason it’s not 5 stars is that thicker 3mm jobs require two people, but that’s expected with manual operation."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Luis Mendez - Maintenance Supervisor, Automotive Plant

"We bought the Pro Model for our maintenance team to fabricate replacement panels and custom mounts. The ±1° accuracy and 4mm stainless steel capacity are impressive—bends come out clean every time. We’ve used it for everything from support brackets to curved guards. The segmented folding system allows complex shapes we used to outsource. After six months of heavy use, it shows zero wear. The 3-year warranty gives us confidence in long-term reliability."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (163 Reviews)

Alex Rivera - Industrial Tooling Consultant

"For small to mid-scale fabricators, the Heavy Duty Manual Sheet Folding Machine offers an optimal balance of precision, durability, and cost-efficiency. The Pro Model’s ±1° accuracy rivals entry-level CNC systems, making it ideal for shops transitioning from basic hand brakes to professional-grade tools—without the energy or maintenance overhead."

Nina Patel - SME Workshop Layout Advisor

"In over a decade of outfitting small fabrication shops, this machine stands out for its multi-scenario adaptability. Whether in a garage or production floor, its compact footprint and manual operation make it one of the most practical investments for custom metalwork."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.