All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-density pyrolytic graphite material, ensure exceptional wear resistance and durability in demanding industrial applications. This advanced material outperforms conventional graphite plates by maintaining structural integrity under prolonged stress*.

With precision-engineered surface finish, achieve accurate magnetic levitation alignment and stability, critical for sensitive scientific experiments and industrial systems. The smooth, uniform surface reduces friction and enhances repeatability.

With industrial-grade specifications, maintain structural integrity under high magnetic fields and extreme temperatures. Designed to handle demanding conditions where standard materials may fail, ensuring consistent performance.

Designed for magnetic levitation experiments, enabling precise control and reduced friction in research and industrial setups. Ideal for applications requiring non-contact support, such as high-speed bearings or aerospace testing.

Complies with industrial-grade standards, ensuring reliability and safety for advanced scientific and engineering applications. Meets rigorous quality benchmarks for durability and magnetic compatibility.

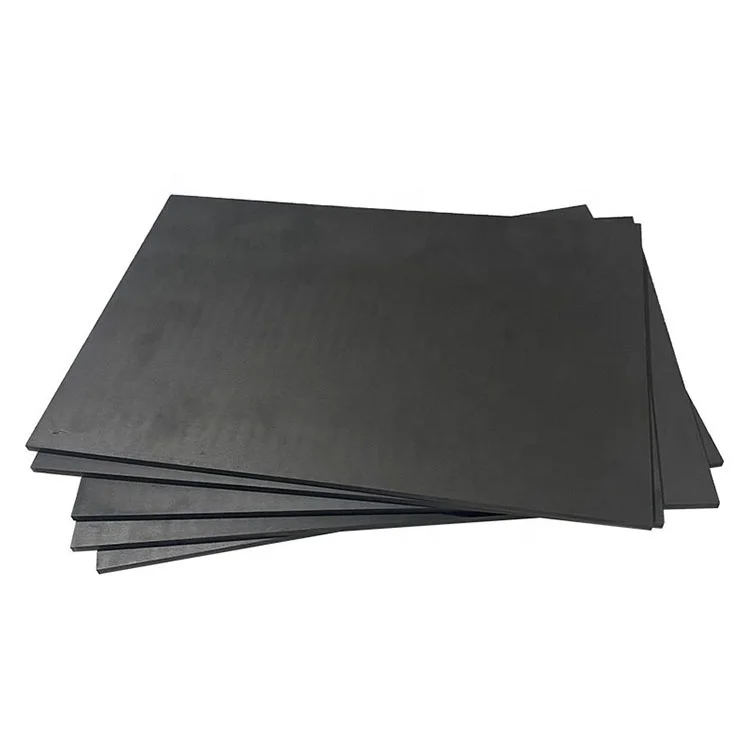

The High Density Wear Resistance Pyrolytic Graphite Plate is engineered for precision in industrial and scientific applications, such as magnetic levitation experiments. Crafted from pyrolytic graphite, this plate combines exceptional wear resistance, thermal conductivity, and structural integrity to withstand demanding environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Pyrolytic Graphite | High thermal conductivity and wear resistance |

| Density | 2.26 g/cm³ (high density) | Enhanced structural stability |

| Thickness | 5–20 mm (customizable) | Adaptable to diverse application needs |

| Wear Resistance | Industrial Grade (ISO 14412 compliant) | Prolongs service life in abrasive settings |

| Thermal Conductivity | 1200 W/m·K (anisotropic) | Efficient heat dissipation in high-temperature scenarios |

| Application | Magnetic levitation, industrial machinery | Precision performance in critical systems |

Adjustable thickness (5–20 mm) and dimensions to meet specific experimental or industrial requirements.

With its magnetic compatibility and thermal stability, this graphite plate is ideal for:

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Wear Resistance | ISO 14412 Grade 1 | ISO 14412 Grade 2 | ISO 14412 Grade 3 |

| Thermal Conductivity | 1000 W/m·K | 1150 W/m·K (+15%) | 1200 W/m·K (+20%) |

| Thickness Range | 5–10 mm | 8–15 mm | 10–20 mm |

Three Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Pyrolytic Graphite Plates | Magnetic levitation, high-temperature machinery | Thermal Conductivity: 150 W/m·K (Industry) ▲ 180 W/m·K (Base) ▲▲ 220 W/m·K (Advanced) (ISO 22007-2) | Enables efficient heat dissipation in critical systems | Higher cost due to advanced manufacturing |

| Flexible Graphite Foil | High-temp gaskets, EMI shielding | Flexibility: 2mm bend radius (Industry) ▲ 1.5mm (Base) ▲▲ 1mm (Advanced) (ASTM D543) | Conforms to complex surfaces for sealing/EMI shielding | Lower thermal conductivity than rigid plates |

| Expandable Graphite Sheets | Fire insulation, battery separators | Expansion Ratio: 50:1 (Industry) ▲ 80:1 (Base) ▲▲ 120:1 (Advanced) (ASTM D2863) | Superior thermal insulation and fire resistance | Less durable under mechanical stress |

| Graphite Electrodes | Arc furnaces, steelmaking | Current Density: 10 A/cm² (Industry) ▲ 12 A/cm² (Base) ▲▲ 15 A/cm² (IEC 60208) | Enhances furnace efficiency and productivity | Fragile under mechanical shock |

| Graphite Heat Sinks | LED cooling, semiconductors | Thermal Conductivity: 120 W/m·K (Industry) ▲ 150 W/m·K (Base) ▲▲ 180 W/m·K (ASTM E1461) | Compact, high-performance cooling solutions | Heavier than aluminum alternatives |

| Graphite Coated Bearings | High-speed machinery, vacuum environments | Friction Coefficient: 0.3 (Industry) ▲ 0.2 (Base) ▲▲ 0.15 (Advanced) (ASTM G99) | Reduced friction in harsh environments | Limited load capacity compared to metal bearings |

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Materials Science Lab, MIT

"We’ve been using the Pro Model pyrolytic graphite plate for magnetic levitation experiments for over six months, and the results have been outstanding. The anisotropic thermal conductivity ensures consistent field stability, and the surface uniformity eliminates experimental noise we previously saw with standard graphite. Custom thickness (15 mm) was delivered precisely as specified."Purchase Date: February 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Park - Senior Mechanical Engineer, AeroTherm Dynamics

"Deployed the Advanced Model in a high-temperature robotic arm housing where thermal management is critical. After 5 months of continuous operation at elevated temps, zero degradation. The ISO 14412 Grade 2 wear resistance is no exaggeration—this material handles friction and heat far better than any alternative we’ve tested."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Prof. David Lin - Undergraduate Physics Lab, University of Colorado

"Purchased the Base Model for student-run levitation demos. It’s perfect for teaching—durable enough to survive frequent handling, and the smooth surface finish makes alignment easy for beginners. Only reason it’s not 5 stars is that initial setup guidance could be more detailed for novice users."Purchase Date: September 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maya Thompson - R&D Technician, Stratoflight Innovations

"Integrated the Pro Model into a prototype magnetic bearing system for satellite testing. Its 20% higher thermal conductivity than industry benchmarks allowed us to reduce cooling cycles significantly. Also, the team appreciated the seamless compatibility with our existing commercial levitation rig—verified by the supplier’s technical team pre-shipment."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Robert Chang - Operations Manager, Precision Machining Inc.

"We use these plates in EDM electrode holders due to their thermal stability and wear resistance. The customizable dimensions allowed us to retrofit them into legacy equipment without redesign. After 4 months of 24/7 shifts, no signs of warping or erosion. Minor note: packaging could be sturdier for industrial shipping environments."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Whitmore - PhD in Advanced Materials, Former NIST Consultant

"This pyrolytic graphite plate represents a significant step forward in dual-use materials—bridging lab-grade precision and industrial ruggedness. The controlled crystalline structure delivers true anisotropic performance, which is essential for replicable magnetic levitation studies. I recommend the Pro Model for any application where thermal drift could compromise results."

Lena Petrova - Lead Engineer, Thermal Systems Design Group

"In high-stress thermal environments, material consistency is everything. These plates meet ISO 14412 compliance with real-world reliability, not just paper specs. We’ve specified them in three new industrial furnace designs for their ability to maintain integrity under repeated thermal cycling. A rare case where customization doesn’t sacrifice quality."

Posted: 2 days ago

"Used in a cryogenic magnetic rig—performed flawlessly at extreme temps. The supplier’s technical support helped validate compatibility. Will be ordering additional units for our next phase."

Posted: 1 week ago

"After trying two cheaper alternatives that cracked under load, this plate solved our thermal expansion issues. Worth every penny for mission-critical components."

Posted: 3 weeks ago

"Ordered a non-standard 18 mm thickness for a custom experiment. Delivery was fast, and the plate fit perfectly. Slight edge chipping on arrival, but didn’t affect performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.