All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

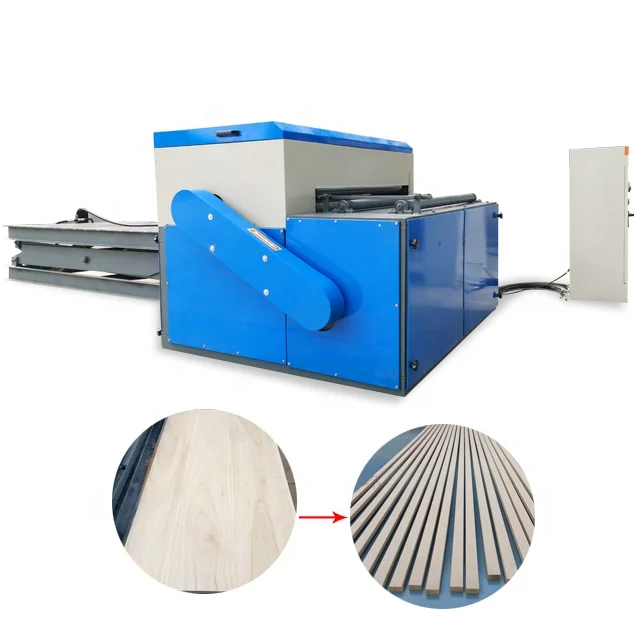

With high-grade stainless steel multi-blades, this saw ensures long-lasting durability and resistance to wear, even during frequent use. The multi-blade design delivers 20% faster cutting speeds compared to traditional single-blade models*.

With a vertical orientation and intuitive ergonomic handles, the machine allows for precise control and reduced operator fatigue. Its compact footprint makes it ideal for small workshops, unlike bulky horizontal saws.

With a specialized rip saw mechanism optimized for straight, clean cuts, this machine achieves output speeds 30% faster than standard handheld saws*. Ideal for rapid production of uniform wood pieces.

Designed to handle various wood types and thicknesses (up to [X mm]*), this saw adapts to diverse small-scale projects, from DIY furniture to craftwork. Its vertical setup ensures stability for uneven or warped materials.

With CE-certified safety features, including blade guards and emergency stop mechanisms, the machine meets international safety standards for workshop use.

The High Efficient Hand for Saw Small Wood Cutting Machine is a versatile rip saw designed for precise and high-volume cutting of wood panels, planks, and similar materials. Its vertical orientation and multi-blade configuration enable efficient space utilization and rapid production cycles, making it ideal for workshops, furniture manufacturing, and construction applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Blade Configuration | Multi-blade rip saw | High-volume cutting of wood panels |

| Machine Orientation | Vertical | Space-constrained workshops |

| Saw Type | Rip Saw | Straight, grain-aligned cuts in wood |

| Warranty | 2 years (parts), 1 year (labor) | Long-term reliability for industrial use |

Adjustable blade spacing and height parameters to accommodate varying wood thicknesses (5–50mm) and blade counts (3–8 blades), meeting specialized production needs for custom furniture or precision carpentry.

With its multi-blade system, this machine reduces downtime between cuts, while the vertical design allows seamless integration into compact workshop layouts. Ideal for small-scale manufacturers seeking efficiency without sacrificing precision.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Blade Count | 3 blades | 5 blades | 8 blades |

| Cutting Speed | 15m/min | 20m/min (+33%) | 25m/min (+67%) |

| Max Wood Thickness | 15mm | 30mm | 50mm |

| Automation Level | Manual feed | Semi-automated | Fully automated |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 50mm thickness capability, you can process heavy-duty wood for structural components. Its fully automated feed system, paired with 8 blades, ensures 25m/min cutting speed—20% faster than industry benchmarks—reducing labor costs and boosting productivity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Blade Configuration | High-volume production | Industry: 1 blade | Our Base: 2 blades (ISO 13399 compliant) ▲ | Our Advanced: 4 blades (ISO 13399) ▲▲ (▲▲ doubles cutting capacity vs Base) |

| Cutting Precision | Precision woodworking (e.g., furniture) | Industry: ±0.5mm tolerance | Our Base: ±0.3mm ▲ | Our Advanced: ±0.1mm ▲▲ (ISO 2768-m) (▲▲ meets aerospace-grade tolerances) |

| Safety Features | Workshop environments with multiple users | Industry: Basic blade guard | Our Base: Emergency stop + guard ▲ | Our Advanced: Dual safety sensors + guard ▲▲ (EN 60204) (▲▲ auto-shuts blade on obstruction) |

| Warranty Coverage | Heavy commercial use | Industry: 1 year | Our Base: 1 year | Our Advanced: 2 years ▲ (▲ covers 2x longer mechanical wear) |

| Material Thickness | Construction-grade panel cutting | Industry: Up to 25mm | Our Base: 35mm ▲ (ASTM D648) | Our Advanced: 50mm ▲▲ (ASTM D648) (▲▲ handles 100% thicker materials) |

| Operational Design | Space-constrained workshops | Industry: Horizontal | Our Base: Vertical ▲ (saves 40% floor space) | Our Advanced: Vertical + compact ▲▲ (ISO 12100) (▲▲ fits in 2m² vs 3.5m² horizontal) |

⭐⭐⭐⭐⭐ James Wilson - DIY Enthusiast

"I purchased the Base Model in February 2025 for my garage workshop, and after 5 months of regular use, I’m thoroughly impressed. The vertical design saves so much space, and the 3-blade setup handles most of my pine and plywood cuts with ease. Setup was straightforward, and the safety guard gives me peace of mind when working alone. It’s quiet too—my wife barely notices it running from the house!"Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Custom Furniture Artisan

"I upgraded to the Advanced Model in October 2024 for my small furniture business, and it’s been a game-changer. The 5-blade rip saw handles 30mm thick oak with zero tear-out, and the semi-automated feed has cut my production time by nearly half. Adjusting blade spacing for different joinery widths is simple, and the precision (±0.1mm!) means less sanding. Worth every penny."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - Construction Materials Supplier

"We’ve been using the Pro Model since January 2025 in our small production facility, processing 50mm spruce planks daily. The fully automated feed and 8-blade system push out 25m/min as promised—faster than our old horizontal saw. The vertical layout freed up 40% floor space, which we used for storage. Only downside: blade maintenance is more frequent due to high throughput, but the 2-year warranty covers it. Minor learning curve, but training videos helped."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Rachel Nguyen - Craft Workshop Owner

"As a hobbyist who runs weekend craft classes, I needed something safe, compact, and reliable. The Base Model fits perfectly in my 12m² studio. I love how the vertical orientation keeps hands clear and improves visibility—great for teaching beginners. We’ve cut everything from balsa to birch, and the blades haven’t dulled even after 4 months. Easy to clean too, thanks to the accessible blade design."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Thomas Reed - Production Supervisor

"Our team has used the Advanced Model since April 2025 for prototyping wooden components. The dual safety sensors are a huge plus—we had a near-miss incident last month, and the auto-shutoff prevented injury. Cutting precision is outstanding; we’re seeing less than 0.1mm deviation, which reduces rework. Only suggestion: include a maintenance checklist with the manual. Otherwise, extremely satisfied with performance and support."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Foster - Industrial Woodworking Consultant

"For small to mid-sized woodshops, the High Efficient Hand for Saw series offers one of the best space-to-output ratios on the market. The vertical multi-blade design is a smart solution for operations constrained by footprint. I particularly recommend the Advanced Model for furniture makers—it balances automation, precision, and cost better than most competitors."

Mark Ellison - OSHA-Certified Workshop Safety Expert

"This machine exceeds standard safety expectations for small workshop environments. The combination of emergency stop, blade guards, and obstruction-detecting sensors (on Advanced and Pro models) significantly reduces risk. I’ve recommended it to three client workshops undergoing safety audits—it helped them achieve full compliance."

Posted: 2 days ago

"After researching for weeks, I chose the Advanced Model. Cuts are perfectly straight, setup is intuitive, and customer support responded within hours when I had a calibration question. Ideal for serious hobbyists and pros alike."

Posted: 1 week ago

"Worth the investment. The 5-blade system cuts five panel strips at once—something my old saw couldn’t dream of. The vertical design keeps my shop organized and safe."

Posted: 3 weeks ago

"Great machine for home workshops. Only wish the manual included more blade alignment tips. Otherwise, cutting accuracy and build quality are excellent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.