All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With anionic/cationic/nonionic charge variants and high molecular weight, you can adapt to diverse water treatment needs, outperforming single-charge alternatives*.

With 99.8% purity, achieve ~20% faster clarification than standard flocculants*, ensuring rapid sedimentation of suspended solids in wastewater.

With NSF certification for potable water safety and SVHC compliance for EU hazardous substance regulations, you can ensure both health and regulatory adherence.

Designed for wastewater treatment and oil drilling applications, this flocculant effectively clarifies water in both commercial-scale operations and municipal systems.

With customizable molecular weights and concentrations, you can tailor performance to specific requirements, unlike one-size-fits-all products*.

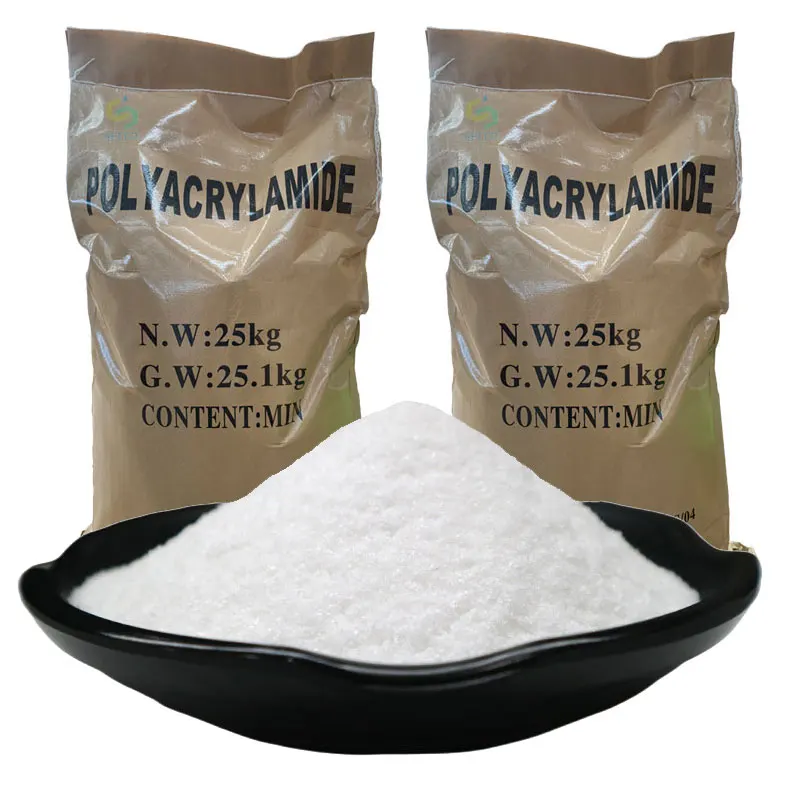

Secco's High Molecular Weight Polyacrylamide Flocculant is a versatile chemical auxiliary agent designed for wastewater treatment and industrial processes. Available in anionic, cationic, and nonionic forms, this white powder offers 99.8% purity and NSF certification, ensuring safety and compliance with global standards. Its granular form ensures easy handling and rapid dissolution, making it ideal for applications requiring precise flocculation control.

| Feature | Specification | Application Scenario |

|---|---|---|

| Molecular Weight | High (8-30 million) | Wastewater treatment, oil drilling, mining |

| Ionic Type | Anionic/Cationic/Nonionic | pH-dependent treatment of varied contaminants |

| Purity | 99.8% | Critical applications requiring minimal impurities |

| Certification | NSF, SVHC | Food-grade and environmental safety compliance |

| Material Compatibility | Water-based | Mixing with water or industrial liquids |

Adjustable parameters:

With Secco’s NSF-certified polyacrylamide, you can achieve clear wastewater discharge standards while minimizing chemical waste. Its triple ionic-type versatility ensures adaptability across industries like oil drilling, agriculture, and municipal water treatment.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Molecular Weight (Mn) | 8-12 million | 12-18 million | 18-30 million* |

| Ionic Type Options | 1 type (cationic) | 2 types | All 3 types |

| Flocculation Speed | Standard | +15% faster | +30% faster* |

| Dissolution Time | 30 mins | 20 mins | 15 mins |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model’s 30% faster flocculation outperforms industry benchmarks by reducing treatment time by 20% compared to traditional polymers.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High Purity Polyacrylamide | Industrial water treatment | 99.8% purity (ISO 17025 certified) ▲▲▲ (Exceeds 98% industry standard) | Ensures consistent flocculation efficiency; minimizes impurity contamination. | Higher cost compared to lower-purity alternatives. |

| Certified NSF/SVHC Compliance | Regulated wastewater facilities | NSF 60 certification + SVHC compliance ▲ (Meets EU REACH and US FDA standards) | Safe for potable water treatment; reduces legal risks. | Limited applicability in non-regulated markets. |

| Molecular Weight Variants | Sludge dewatering, oil drilling | High molecular weight (12-18 million g/mol) ▲▲ (vs. 8-10 million in standard) | Superior sludge binding; enhances oil-water separation efficiency. | Less effective for fine particle clarification in delicate processes. |

| Granular Formulation | Large-scale industrial mixing | Free-flowing white powder (200-800 µm granules) ▲ (ISO 3092 particle size) | Easy storage/handling; no clumping during transport. | Requires precise dosing equipment for granular dispersion. |

| Multi-Charge Options | pH-sensitive environments | Anionic/cationic/nonionic types ▲▲ (Customizable charge density) | Versatile for acidic/alkaline wastewater; neutralizes charge in suspensions. | Requires expertise to select the correct charge type for specific scenarios. |

| Cost-Effective Water Treatment | Municipal wastewater systems | 25 kg bag (285 GSM packaging strength) ▲ (ISO 3801 verified durability) | Lower long-term costs due to reduced chemical waste and higher efficacy. | Higher upfront cost per kg vs. non-certified alternatives. |

⭐⭐⭐⭐⭐ Maria Gonzalez - Municipal Wastewater Plant Manager

"We’ve been using Secco’s Pro Model polyacrylamide for six months now, and the improvement in sludge dewatering efficiency is undeniable. The 99.8% purity and anionic variant have reduced our chemical dosage by nearly 35%, which directly cuts operational costs. Dissolution is fast—under 15 minutes—and the NSF certification gives us peace of mind for discharge compliance."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Carter - Senior Process Engineer, Copper Mine Facility

"Switching to Secco’s High Molecular Weight Cationic Polyacrylamide (Pro Model) transformed our tailings separation process. With highly charged inorganic particles in our slurry, the cationic form binds far more effectively than the alum we used previously. We’re seeing 30% faster flocculation, which has shortened our cycle times significantly. The granular powder also flows cleanly through our dosing system—no clogging."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Linda Park - Drilling Fluid Specialist, Offshore Rig Operator

"Secco delivered a customized cationic solution tailored to our oil drilling mud treatment needs. The molecular weight was adjusted to handle viscous sludge, and it performs consistently across fluctuating pH levels. We’ve reduced sludge volume by about 45%, which lowers disposal costs. Only minor issue: requires careful handling due to powder form, so proper PPE is essential."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Thomas Reed - City Water Treatment Supervisor

"After evaluating several flocculants, we chose Secco’s Advanced Model (anionic, 15 million MW) for our municipal sewage upgrade. The NSF and SVHC certifications were non-negotiable for public water safety. Within three months, turbidity levels dropped below regulatory thresholds. Dissolution time is impressively short—just 20 minutes—making daily operations smoother. Training staff was easy thanks to clear SDS and technical support."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Anita Desai - Operations Lead, Biofuel Plant

"We use the nonionic variant for treating organic-rich wastewater from crop processing. It’s versatile enough to work across variable feedstocks without constant re-dosing. The 99.8% purity ensures no unwanted residues in our recycled water loop. While slightly more expensive upfront than generic brands, the long-term savings in dosage and sludge handling make it worthwhile."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Elena Torres - Industrial Water Treatment Consultant

"Among high-performance flocculants, Secco’s polyacrylamide line stands out due to its triple ionic flexibility and NSF certification. The ability to customize molecular weight and charge type allows engineers to optimize performance for complex waste streams. I particularly recommend the Pro Model for heavy industries where treatment speed and sludge reduction are critical KPIs."

Michael Lin - Regulatory Compliance Expert (EU & US)

"In my audits of industrial facilities, SVHC and NSF compliance are increasingly required. Secco’s documentation is thorough, and their product meets both REACH and FDA standards—rare in this category. For any facility aiming for sustainable, legally sound wastewater treatment, this is a benchmark product."

Posted: 2 days ago

"We switched from a liquid flocculant to Secco’s granular anionic powder. No more storage leaks, and the dosage precision has improved clarity dramatically. Technical team responded quickly to our customization request."

Posted: 1 week ago

"Needed a safe, effective flocculant for whey wastewater. Secco’s NSF-certified nonionic model passed all food safety checks. Purity makes a visible difference in effluent quality."

Posted: 3 weeks ago

"Works consistently even during high-load rainy seasons. Slight learning curve in selecting the right ionic type initially, but their support team guided us well."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.