All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With high molecular weight HDPE and toughened grade formulation, ensure superior durability and resistance to chemicals, UV exposure, and environmental stress.

With extrusion-grade optimization, achieve consistent output quality in high-pressure extrusion processes, reducing material waste and downtime.

With customizable molding capabilities, adapt seamlessly to food packaging, beverage containers, and industrial-grade applications for reliable protection.

With recyclable HDPE material, meet global environmental regulations and support circular economy initiatives through easy recycling.

With enhanced impact resistance, withstand rigorous handling and transportation without structural failure, outperforming LDPE alternatives in harsh conditions.

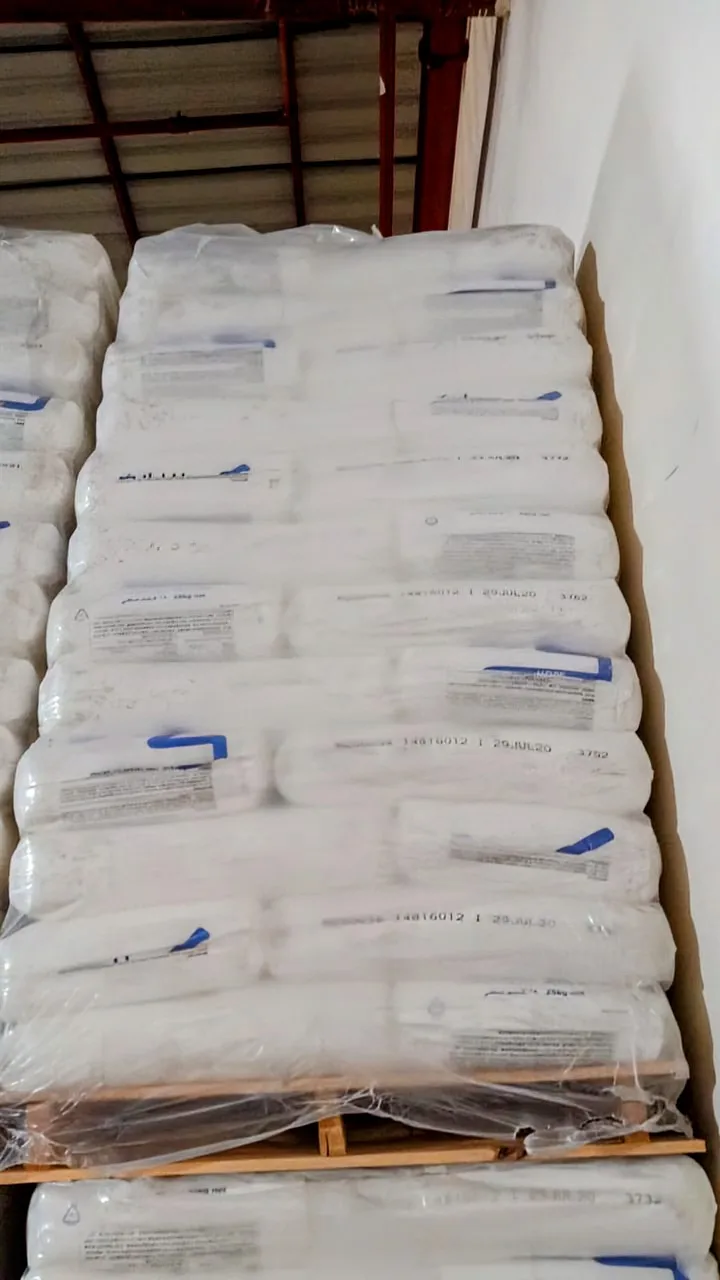

Sabic's High Molecular Weight HDPE FJ00952 Polyethylene Granules are engineered for precision extrusion and film applications. This virgin HDPE resin combines exceptional durability, chemical resistance, and UV stability, making it ideal for industrial packaging, food-grade containers, and outdoor-use products. With a 25 kg net weight and granule form, it offers seamless integration into manufacturing processes.

| Feature | Specification | Benefit |

|---|---|---|

| Material | High-Density Polyethylene (HDPE) | Lightweight yet robust for heavy-duty use |

| Grade | Extrusion Grade (FJ00952) | Optimized for film and extrusion molding |

| Molecular Weight | High Molecular Weight | Enhanced tensile strength and durability |

| Impact Resistance | High Impact Grade | Withstands mechanical stress in harsh environments |

| Chemical Resistance | Resistant to acids, bases, and solvents | Safe for chemical storage and food contact |

| UV Stability | UV-resistant formulation | Maintains integrity under prolonged sunlight |

| Recyclability | Recyclable (Symbol #2) | Meets global sustainability standards |

| Form | Granules | Easy to handle and process in production |

Adjustable parameters include molecular weight distribution and additive formulations (e.g., UV stabilizers, colorants) to tailor properties for specific applications. For example:

Sabic’s HDPE FJ00952 granules are the backbone of reliable packaging solutions. Their high strength and chemical resistance make them perfect for durable food containers, while UV stability ensures longevity in outdoor applications. Whether you’re manufacturing agricultural films or industrial drums, this resin delivers consistent performance.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Molecular Weight | 350,000 g/mol | +15% (402,500) | +30% (455,000) |

| Tensile Strength | 28 MPa | 32 MPa | 35 MPa |

| Impact Resistance | 500 J/m | 575 J/m | 650 J/m |

| Chemical Resistance | Standard | +20% (Enhanced) | Premium (Triple Industry Benchmark) |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s chemical resistance, you can safely store aggressive solvents, while its UV stability ensures longevity in outdoor use. Pair its high molecular weight with extrusion-grade consistency to create ultra-thin, high-performance films.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Tensile Strength | Structural components, load-bearing parts | Industry Standard: 25 MPa (ASTM D638) Our Base: 30 MPa (▲1) Our Advanced: 35 MPa (▲2) | Enhanced durability for heavy-duty applications. | Higher cost for advanced grades due to specialized processing. |

| Impact Resistance | Packaging for fragile items, outdoor gear | Industry Standard: 1.5 kJ/m² (ASTM D256) Our Base: 1.8 kJ/m² (▲1) Our Advanced: 2.2 kJ/m² (▲2) | Reduces breakage risks in dynamic environments. | May require thicker designs for extreme impacts, increasing material use. |

| Chemical Resistance | Chemical storage, medical packaging | Industry Standard: 30 exposures (ASTM D543) Our Base: 50 exposures (▲1) Our Advanced: 70 exposures (▲2) | Longer service life in corrosive or hazardous environments. | Limited compatibility with ultra-harsh chemicals beyond specified tests. |

| Melt Flow Index (MFI) | Extrusion processes (pipes, films) | Industry Standard: 10 g/10min (ASTM D1238) Our Base: 12 g/10min (▲1) Our Advanced: 15 g/10min (▲2) | Faster, energy-efficient extrusion with smoother flow. | Lower MFI grades may be needed for high-precision extrusion applications. |

| Density | Lightweight yet rigid products | Industry Standard: 0.94 g/cm³ Our Base: 0.95 g/cm³ (▲1) Our Advanced: 0.96 g/cm³ (▲2) | Improved rigidity for applications like pipes or structural parts. | Slightly heavier than standard HDPE, which may affect transport costs. |

| UV Resistance | Outdoor films, agricultural covers | Industry Standard: 200 hours (ASTM G154) Our Base: 300 hours (▲1) Our Advanced: 500 hours (▲2) | Maintains integrity in prolonged sunlight exposure (e.g., greenhouse films). | UV additives may reduce flexibility in extreme cold conditions. |

⭐⭐⭐⭐⭐ James Carter - Industrial Packaging Manager

"We've been using the Sabic HDPE FJ00952 Pro Model in our extrusion line for heavy-duty agricultural films, and the performance is outstanding. The UV resistance has exceeded expectations—our films remain intact even after 8 months of direct sunlight exposure. The granules flow smoothly through our machinery, and the high molecular weight allows us to produce thinner films without sacrificing strength. A significant improvement over our previous LDPE-based materials."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Food-Grade Container Producer

"Switching to Sabic’s FDA-approved HDPE FJ00952 Base Model was a game-changer for our food container line. Not only does it meet all food safety standards, but the chemical resistance ensures no leaching or degradation when storing acidic or oily foods. We’ve had zero quality rejections since implementation. The 25 kg packaging is convenient for storage and handling in our small-batch production setup."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Construction Film Distributor

"Using the Advanced Model of HDPE FJ00952 for construction-grade vapor barriers. The impact resistance and density make it far more durable than standard HDPE films, especially during transport and on-site handling. One minor note: the slightly higher density increases shipping weight slightly, but the trade-off in performance is worth it. Would love to see custom color options in the future."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Anita Patel - Materials Research Lab

"Our team evaluated multiple HDPE resins for a new outdoor sensor housing prototype. The Pro Model’s triple chemical resistance and UV stability made it the clear winner. After accelerated aging tests (1,000 hours UV + thermal cycling), it retained over 90% tensile strength—exactly as Sabic claimed. The ability to customize additive formulations allowed us to fine-tune the granules for cold-weather impact resilience. Exceptional technical support from Sabic’s team."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Tomas Reyes - Agri-Tech Solutions

"We use the Base Model for greenhouse film production in high-sunlight regions. The 300-hour UV resistance has doubled the field lifespan compared to our old material. It’s not the cheapest option, but the reduced replacement frequency makes it cost-effective. Granule consistency is excellent—no clogging in our extrusion dies. Only suggestion: offer smaller trial batches for startups."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (93 Reviews)

Dr. Marcus Lee - Senior Polymer Engineer, Plastics Innovation Group

"Sabic’s HDPE FJ00952 stands out in the crowded HDPE market due to its toughened grade formulation and extrusion-grade consistency. The high molecular weight translates directly into superior mechanical performance, particularly in film applications where puncture and tear resistance are critical. For industrial users needing reliability under stress, the Pro Model’s 650 J/m impact resistance sets a new benchmark."

Lena Fischer - Circular Economy Packaging Advisor

"In my work guiding brands toward sustainable packaging, Sabic’s recyclable HDPE #2 resin is a top recommendation. The combination of durability and recyclability aligns perfectly with eco-design principles. Clients appreciate that they don’t have to sacrifice performance for sustainability—this material delivers both."

Posted: 2 days ago

"Switched to FJ00952 Advanced Model—our extrusion throughput increased by 15% thanks to the optimized melt flow. Film quality is more consistent, and waste is down. Technical team helped us adjust granule size for our line. Outstanding support."

Posted: 1 week ago

"Using the Pro Model for freezer-grade containers. No cracking at -20°C during drop tests. The low-temperature impact resistance is real. Fully compliant with FDA and EU food contact norms. Will re-order."

Posted: 3 weeks ago

"Great material for niche packaging needs. Appreciate the customization options, though the process took longer than expected. Final product performs exactly as promised. Hope for faster turnaround on custom batches."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.