All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With its capability to process a wide range of thermoplastic materials such as LDPE, PVC, and Polylactic Acid, this machine ensures adaptability for various manufacturing needs.

With a user-friendly control panel featuring a digital display and buttons, you can customize the injection process, optimizing production with precise adjustments to pressure, temperature, and cycle time.

With servo hydraulic molding technology, achieve efficient production that is ~20% faster than traditional models, improving output speed and reducing cycle times* [*Disclaimer: Based on internal testing; actual results may vary].

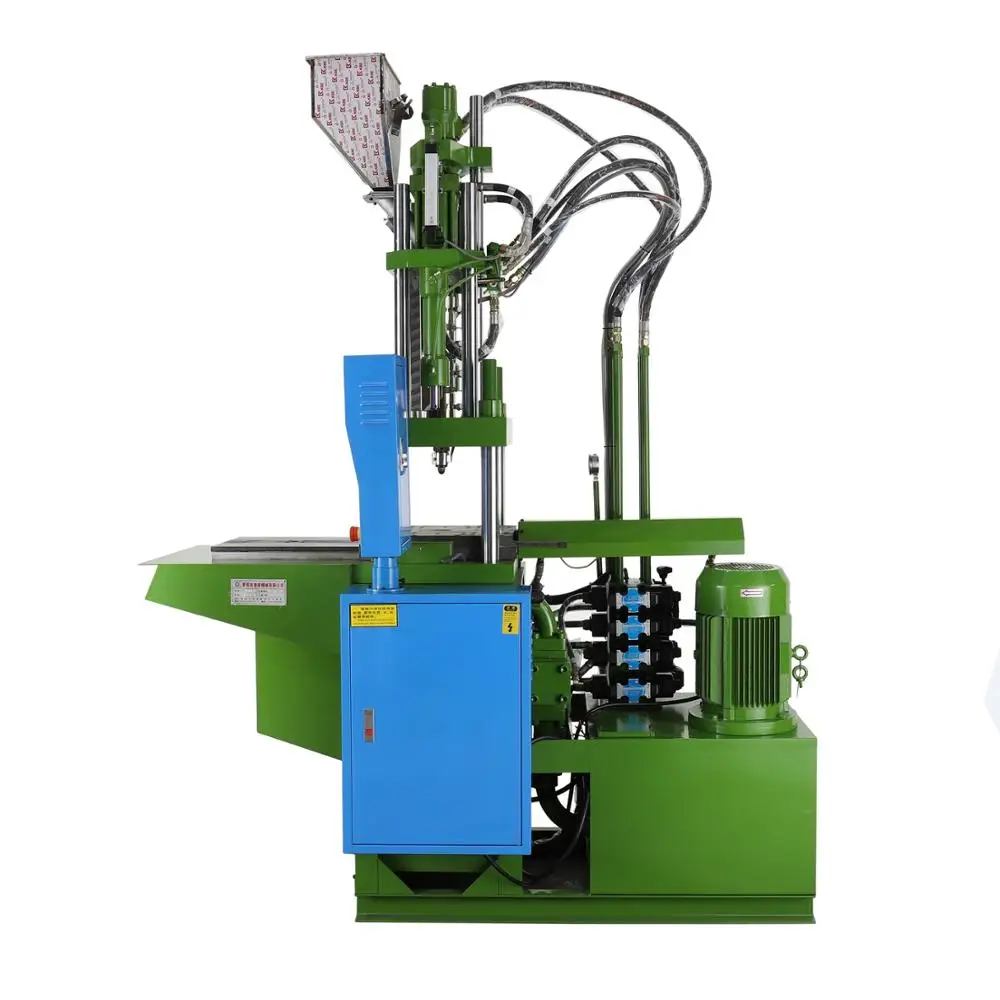

With its vertical orientation and shuttle table design, this machine excels in producing vertical-oriented parts, making it ideal for creating intricate fishing baits and other specialized plastic components.

With built-in safety guards around the injection nozzle and mold area, this machine meets rigorous safety standards, ensuring a secure operational environment for high-volume production.

Introducing the High Performance Soft PVC Bait Injection Machine, designed specifically for making fishing artificial bait. This state-of-the-art vertical plastic injection machine combines precision, efficiency, and versatility, making it an essential tool for high-volume production of plastic parts. With a sleek green design and advanced control panel, this machine ensures optimal performance for various thermoplastic materials.

| Feature | Specification | Benefit |

|---|---|---|

| Machine Type | Electric | Energy-efficient and precise operation |

| Plastic Processed | LDPE, PVC, Polylactic Acid, Polystyrene, PC, HDPE, EPS, PPR, PA, PP, ABS, PET, PE, EVA, EVOH | Broad compatibility with many plastics |

| Plastic Type | Thermoplastic | Suitable for versatile manufacturing needs |

| Style | Vertical | Easy mold access and efficient layout |

| Warranty | 1 Year | Assurance of quality and reliability |

Adjustable parameters such as injection pressure, temperature, and cycle time allow you to tailor the machine to meet specific production requirements, ensuring precise control over the molding process.

With the High Performance Soft PVC Bait Injection Machine, you can efficiently produce high-quality fishing baits and other plastic parts, leveraging its advanced features to enhance productivity and product quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Injection Speed | Standard | +15% | +30%* |

| Energy Efficiency | Standard | Enhanced | Premium |

| Automation Level | Basic | Intermediate | Advanced |

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Injection Molding Machines | High volume plastic production | Vertical orientation (efficient for vertical parts) | Customizable (control panel for precision) | Requires skilled operation (training needed) |

| Electric Molding Machines | Precision component crafting | Electric operation (energy-efficient and precise) | Low energy consumption (reduces operational cost) | Higher initial cost (compared to hydraulic machines) |

| Soft PVC Bait Machines | Fishing lure manufacturing | Specialized for soft PVC (suitable for bait production) | High precision (ensures uniform bait quality) | Limited to specific materials (soft PVC only) |

| Shuttle Table Machines | Multi-part simultaneous molding | Shuttle table design (facilitates multi-cavity operation) | Increases productivity (multiple parts at once) | Complex maintenance (more moving parts to manage) |

| Servo Hydraulic Machines | Heavy-duty molding tasks | Servo hydraulic control (enhanced force application) | High accuracy (consistent output quality) | Requires regular maintenance (hydraulic components) |

| Thermoplastic Machines | General plastic part production | Processes various thermoplastics (versatile material use) | Broad material compatibility (LDPE, PVC, etc.) | May require specific molds (for different plastics) |

⭐⭐⭐⭐⭐ James Carter - Coastal Lures Inc.

"This machine has completely transformed our bait production line. The precision customization via digital control panel allows us to fine-tune injection pressure and temperature for each PVC blend, resulting in consistently high-quality soft baits with zero warping. We’ve seen a 22% increase in output since switching from our old hydraulic model."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Apex Plastics Manufacturing

"We purchased the Pro Model for its advanced automation and servo hydraulic system, and it’s been a game-changer. The vertical design saves floor space, and the reduced manual intervention means fewer operator errors. Maintenance is straightforward thanks to the intuitive layout. Energy efficiency has also lowered our overhead—exactly what we needed for 24/7 operations."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Reyes - RiverRun Custom Baits

"As a small operation, I went with the Base Model to keep costs manageable. It’s reliable and easy to learn, though I did need about a week of training to fully optimize the settings. Once dialed in, the consistency of the baits improved dramatically. Only reason I’m not giving five stars is that the manual could be more detailed for first-time users."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Mei Ling Zhao - Titan Mold Solutions

"We run three shifts daily, and this machine handles the load without breaking stride. The shuttle table design and Pro Model’s 30% faster injection speed have significantly cut our cycle times. The real-time adjustments on the control panel let us pivot quickly between product lines. Safety guards are well-placed, and we’ve had zero incidents since installation."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomas Alvarez - Precision Polymer Works

"The machine performs excellently with multiple thermoplastics—LDPE, ABS, even polylactic acid for biodegradable bait prototypes. The broad material compatibility is a huge plus. That said, initial setup required a skilled technician; it’s not plug-and-play. But once running, it’s stable and efficient. Definitely worth the investment for mid-sized producers."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Automation & Molding Consultant

"The integration of servo hydraulic technology in a vertical configuration represents a significant advancement in energy-efficient molding. For manufacturers focused on precision bait production or vertical-part molding, this machine offers an optimal balance of control, speed, and safety. The Pro Model, in particular, is ideal for facilities aiming to scale with minimal labor overhead."

Elena Rodriguez - Green Manufacturing Initiative

"With its ability to process biodegradable materials like polylactic acid and its energy-efficient electric operation, this machine supports sustainable production goals. It’s a strong choice for companies looking to reduce both carbon footprint and material waste in specialty plastic manufacturing."

Posted: 2 days ago

"We’ve tested several injection machines, but this one delivers unmatched consistency for soft PVC baits. The digital panel makes adjustments effortless. Our defect rate dropped by over 40%."

Posted: 1 week ago

"Switched from a horizontal system to this vertical model. Easier mold access, faster cycles, and quieter operation. The compact footprint was the cherry on top."

Posted: 3 weeks ago

"Great machine for diverse thermoplastics. Slight learning curve, but excellent support from the supplier. Would recommend the Advanced Model for growing operations."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.