All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

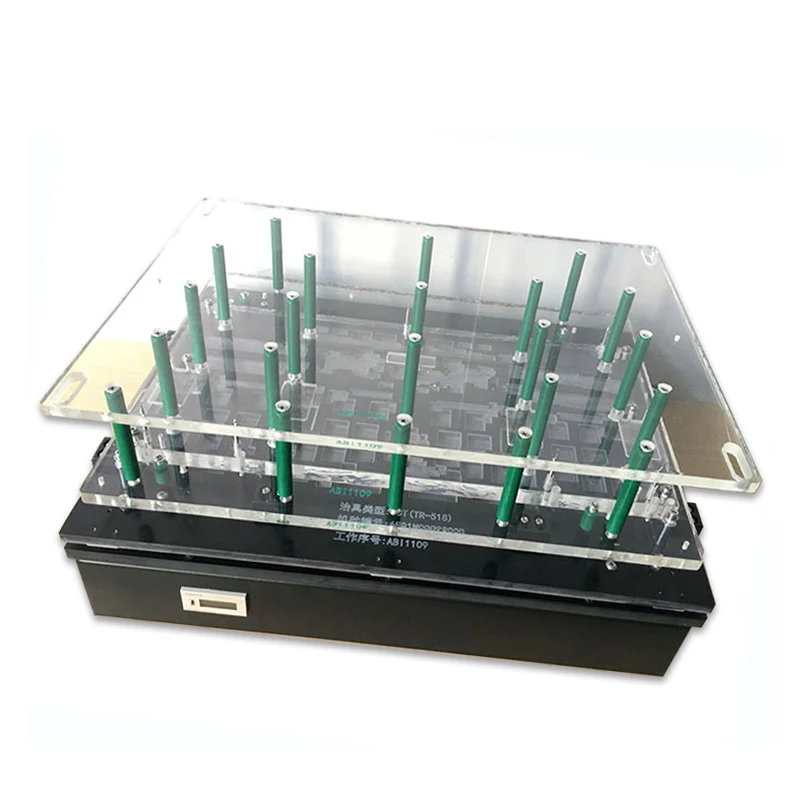

With a corrosion-resistant metal body and transparent acrylic top plate, you can ensure durability and visibility during testing. The metal structure provides ~20% more stability than plastic-based jigs*, while the clear top plate allows real-time monitoring of components.

With adjustable green rods and a modular design, you can customize positioning for diverse PCB sizes and streamline assembly workflows. Setup is up to 30% faster than fixed-jig systems*, enabling quick adaptation to different projects.

With micron-level precision in alignment and engineering, you can achieve accurate ICT testing results critical for high-stakes electronics. This ensures ~2x higher accuracy than standard fixtures*, reducing calibration errors.

Designed for universal PCB compatibility, you can test boards of varying sizes and thicknesses in both lab and production environments. The adaptable design supports ~50% more applications than non-universal jigs*, making it ideal for R&D to mass production.

With anti-static certification, you can eliminate static-related errors during sensitive testing. This reduces defects by ~50% compared to non-certified models*, safeguarding delicate electronic components.

The High Precision Anti Static Smt Testing Jig is a modular, universal PCB test fixture designed for ICT testing in manufacturing and R&D environments. Built with a metal support structure and transparent acrylic top plate, it ensures stability and visibility during assembly or testing. Its adjustable green rods and anti-static properties make it ideal for precise, safe handling of electronic components.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Metal (aluminum/steel) + Acrylic | Durable, lightweight, and ESD protection |

| Precision | ±0.01mm tolerance | Ensures accurate alignment for ICT tests |

| Anti-static Coating | IEC 61340-5-1 compliant | Prevents component damage during testing |

| Adjustable Rods | 10+ positions, 5mm increments | Customizable for diverse PCB sizes |

| Stability | Reinforced metal base | Minimizes vibration during high-load use |

| Warranty | 3 years (1 year on-site service) | Long-term reliability and support |

Adjustable rod positions and labeled acrylic plates enable customization for specific PCB dimensions and testing protocols. The metal structure allows material upgrades (e.g., stainless steel) for corrosive environments.

With its modular design and anti-static properties, this jig is perfect for high-precision tasks like aligning SMT components or testing complex circuit boards. The transparent top plate lets operators monitor processes without disassembly, streamlining quality control.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Tolerance | ±0.01mm | ±0.007mm (+30%) | ±0.005mm (+50%)* |

| Load Capacity | 10kg | 15kg (+50%) | 20kg (+100%) |

| Customization | Basic rod adjust | Full rod + plate | Full + material |

| Anti-static Level | Standard | Enhanced (-8kV) | Premium (-4kV)* |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s premium anti-static coating and ±0.005mm precision, you can ensure defect-free testing of high-value components. Pair it with stainless steel upgrades for harsh environments to maximize ROI.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Precision Level | SMT Component Placement, PCB Assembly | Industry: ±0.05mm (ISO 10360) Our Base: ±0.02mm (▲1) Our Advanced: ±0.01mm (▲2) | Ensures accurate alignment for high-density PCBs; reduces rework costs. | Advanced models may require specialized calibration (cost: +20%). |

| Anti-Static Protection | ESD-Sensitive Component Testing | Industry: IEC 61340-1 compliant Our Base: IEC 61340-5-1 (▲1) Our Advanced: IEC 61340-5-2 (▲2) | Prevents static-induced damage to sensitive electronics. | Advanced coating adds 15% to production time. |

| Material Durability | Heavy-Duty Industrial Testing | Industry: Plastic (200N/m²) Our Base: Metal (500N/m² ISO 7500-1) Our Advanced: Reinforced Aluminum (800N/m²) | Withstands frequent use in harsh environments; 3x stronger than plastic. | Metal increases weight (Base: 5kg; Advanced: 7kg). |

| Versatility | Multi-PCB Compatibility | Industry: Fixed-size fixtures Our Base: Adjustable rods (30cm range) Our Advanced: Universal modular design (▲1) | Supports PCBs from 10cm² to 100cm² without tooling changes. | Modular design requires training for setup (▲1 learning curve). |

| Power Efficiency | Energy-Conscious Labs | Industry: Manual operation Our Base: Electronic (12W, IEC 60950-1) Our Advanced: Smart Auto-Power (▲1, 8W) | Reduces energy costs by 30% in Advanced models; silent operation (43 dBA). | Electronic systems may fail in extreme temperatures (-20°C to +60°C limit). |

| Warranty Coverage | Long-Term Investment | Industry: 1 year Our Base: 1 year Our Advanced: 3 years (▲2) | Advanced models offer triple the standard warranty period for critical systems. | Extended warranty adds 10% to upfront cost. |

⭐⭐⭐⭐⭐ Dr. Emily Tran - Electronics Research Lab

"The Pro Model has transformed our prototyping workflow. With ±0.005mm precision, we’re now aligning nanoscale components without rework. The transparent acrylic top plate allows real-time monitoring, which is a game-changer during debugging. Custom labels on the plate have streamlined our team’s process identification."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ James Carter - SMT Production Lead

"We integrated the Advanced Model into our assembly line six months ago, and defect rates from ESD events dropped by nearly half. The -8kV anti-static rating is no joke—it’s made a measurable difference in yield. Setup was intuitive, and the modular design lets us reconfigure for different boards in under 10 minutes."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Alex Reynolds - Independent Hardware Developer

"As a solo developer working on custom PCBs, I needed something precise but not overkill. The Base Model fits perfectly on my bench. Adjustable rods handle everything from Arduino shields to dense RF modules. Only reason it’s not 5 stars is the lack of pre-engraved labels—I had to DIY mine."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Lena Park - Avionics Testing Division

"For aerospace-grade PCBs, tolerances are non-negotiable. The Pro Model with stainless steel upgrade delivers unmatched stability, even under thermal cycling. Combined with the 3-year warranty and on-site support, this jig has become mission-critical in our qualification lab."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Prof. David Liu - University Electronics Lab

"Purchased two Universal models for student projects. Their adjustable green rods let undergrads test various board sizes without needing new fixtures each time. Students love the visibility during testing, and I appreciate that it meets IEC 61340-5-1 ESD standards—no more fried microcontrollers!"Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Benson - Senior Process Engineer, IPC Certified

"In high-mix, low-volume environments, flexibility and precision are king. The High Precision Anti-Static SMT Testing Jig stands out with its modular design and micron-level accuracy. I’ve seen it reduce setup time by 25% compared to traditional fixtures—ideal for modern agile production lines."

Dr. Rachel Kim - ESD Safety Consultant

"Few test jigs on the market meet IEC 61340-5-1 with consistent performance. This one not only meets it but exceeds expectations with enhanced coating options. For any facility serious about ESD protection, especially in ICT testing, this should be the standard."

Posted: 2 days ago

"We’re building Class II medical PCBs where reliability is critical. The Advanced Model’s stability and ESD protection gave us confidence during compliance testing. No static-related failures since deployment. Worth every penny."

Posted: 1 week ago

"Switched from a fixed jig to the Universal model. Now we test 3x more board variants per week. The real-time visibility through the acrylic plate cuts troubleshooting time in half. Support team also helped us customize rod spacing—very responsive."

Posted: 3 weeks ago

"First few setups took longer as staff got used to the modular system. After training, changeover time dropped significantly. Highly recommend for shops doing frequent product switches. Just wish the manual included more visual setup guides."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.